Manufacturing method of highly corrosion-resistant/mildew-proof bamboo scrimber

A technology of bamboo recombined wood and manufacturing methods, applied in the direction of manufacturing tools, pretreatment of molding materials, flat products, etc., can solve the problems of short protection period, increased permeability, infection, etc., to improve anti-mildew and anti-corrosion performance, strengthen adhesion Synergistic effect, strong operability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The manufacturing method of the strong anti-corrosion / mildew-proof bamboo reconstituted material of the present embodiment comprises the following steps:

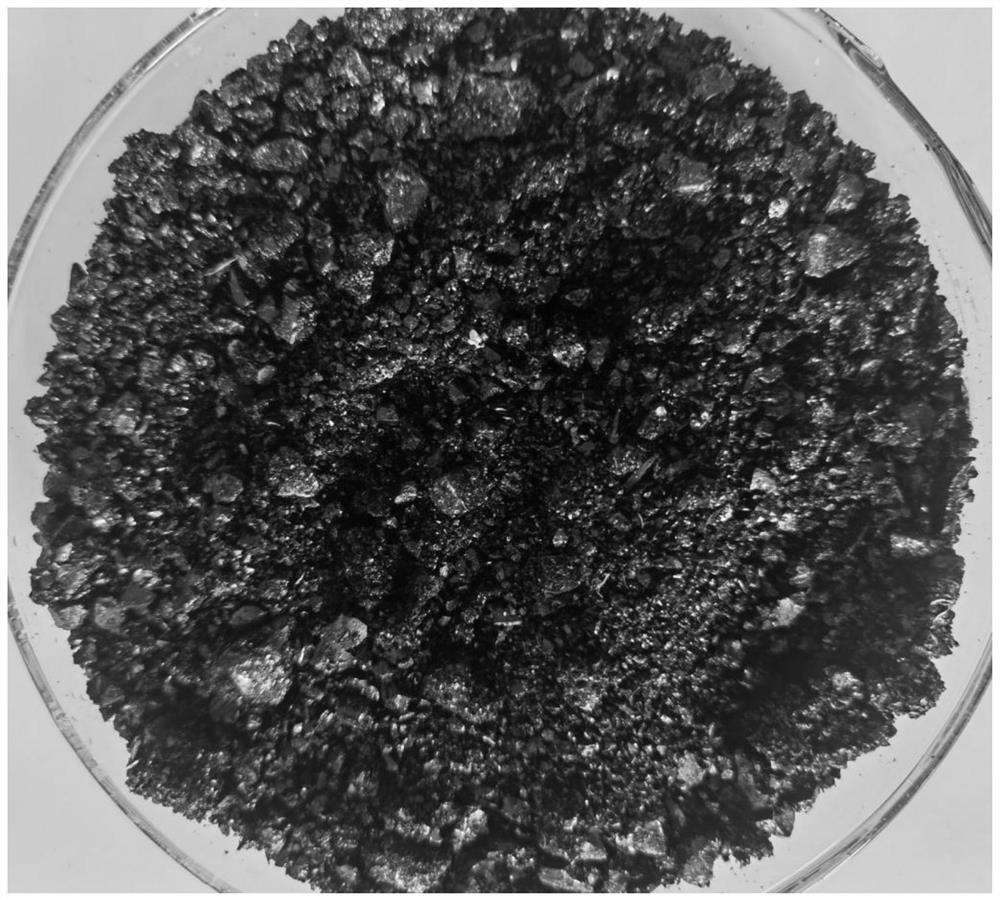

[0038] S1. Pretreatment of loosening bamboo bundles: drying the loosening bamboo bundles at a temperature of 50°C to a moisture content of 8%, heating the alkylnaphthalene type heat-conducting oil to 180°C, adding No. Bamboo bundles were dipped in it for 2min, taken out and drained immediately, to obtain pretreated post-removal bamboo bundles; the addition of described No. 10 pitch was 5% of the heat-conducting oil weight;

[0039] Under the action of high temperature, the pretreated bamboo bundles will decompose and destroy nutrients, reduce hydrophilic groups, increase dimensional stability (cold-heat expansion and dry-wet deformation), and the surface layer penetrates strong anti-corrosion components of asphalt;

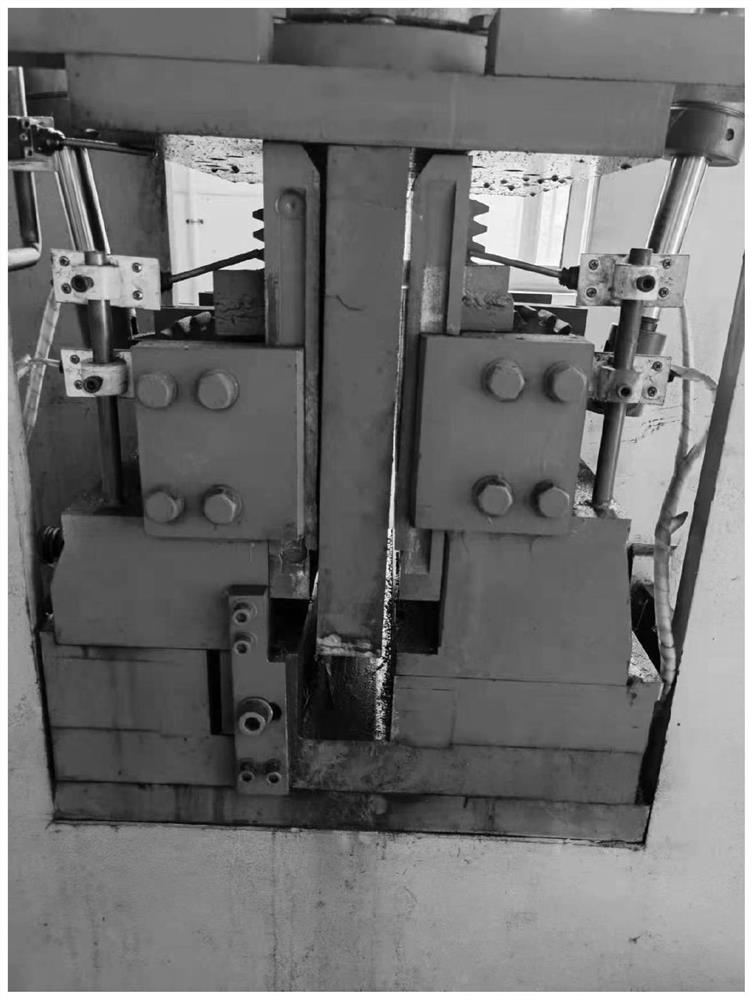

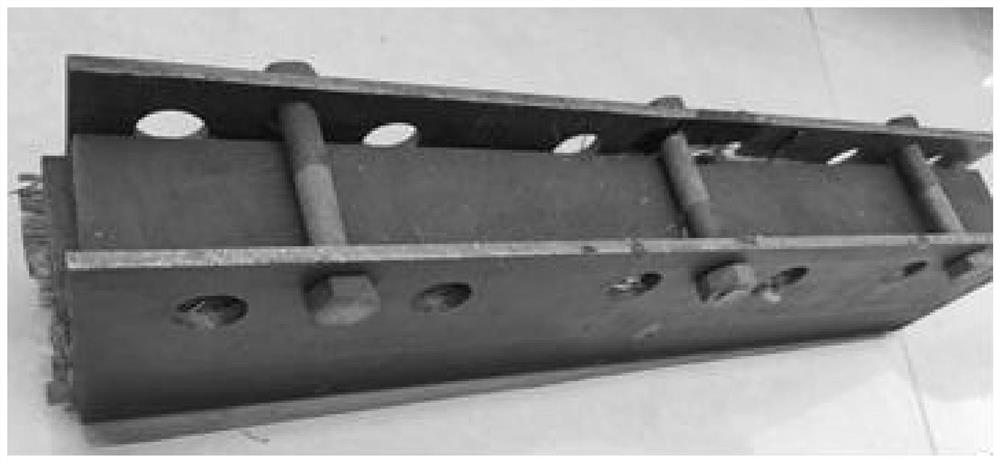

[0040] S2. Cold-pressed molding: grind No. 10 block asphalt at a temperature of 9°C, then add polyphe...

Embodiment 2

[0050] The manufacturing method of the strong anti-corrosion / mildew-proof bamboo reconstituted material of the present embodiment comprises the following steps:

[0051] S1. Pretreatment of loosening bamboo bundles: drying the loosening bamboo bundles at a temperature of 60°C to a moisture content of 12%, heating the alkylnaphthalene type heat-conducting oil to 160°C, adding No. 10 pitch, and drying the dried bamboo bundles Bamboo bundles were dipped in it for 8min, taken out and drained immediately, to obtain pretreated post-removal bamboo bundles; the addition of described No. 10 pitch was 10% of the heat transfer oil weight;

[0052] S2. Cold pressing: Grind No. 10 block asphalt to a powder with a particle size of less than 2 mm at a temperature of 8 °C, then add polyphenol antioxidant 1010 and mix evenly to obtain asphalt mixed powder; Adding bamboo fiber scraps with a length of 0.5 mm to 4 mm into the asphalt mixture powder, and mixing evenly to obtain a mixture of asphal...

Embodiment 3

[0060] The manufacturing method of the strong anti-corrosion / mildew-proof bamboo reconstituted material of the present embodiment comprises the following steps:

[0061] S1. Pretreatment of loosened bamboo bundles: drying the loosened bamboo bundles at a temperature of 80° C. to a moisture content of 10%, heating the cooked tung oil to 200° C., adding No. 10 pitch, and dipping the dried loosened bamboo bundles in Wherein 6min, take out and drain immediately, obtain the pretreatment post-relief bamboo bundle; The addition of described No. 10 pitch is 8% of the weight of the heat-conducting oil;

[0062] S2. Cold pressing: Grind No. 10 block asphalt to a powder with a particle size of less than 2 mm at a temperature of 6 °C, then add polyphenol antioxidant 1076 and mix evenly to obtain asphalt mixed powder; Add bamboo fiber scraps with a length of 0.5 mm to 4 mm into the asphalt mixture powder, and mix them evenly to obtain an asphalt bamboo fiber mixture; the addition amount of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com