Flame retardant as well as preparation method and use method thereof

A technology of flame retardant and boron-based flame retardant, which is applied in the field of 3D printing, can solve the problems of difficulty in uniform mixing of flame retardant and foundry sand, and easy reaction with curing agent, so as to improve curing strength and flame retardant performance, Effect of preventing porosity and improving casting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The second purpose of the present invention is to disclose the preparation method of the above-mentioned flame retardant, which comprises the following steps:

[0026] S1. According to the needs, design the distribution ratio of each component of boron-based flame retardant and / or covering flame retardant, and weigh the raw materials according to the component distribution ratio;

[0027] S2. Place the raw material in a ball mill, and mill it for 1 to 2 hours to obtain fine powder;

[0028] S3. Use each mesh screen to sieve the fine powder to obtain the corresponding mesh fine powder;

[0029] S4. According to needs, design the particle size ratio of the flame retardant, weigh and mix the fine powder of the corresponding mesh number according to the particle size ratio to obtain the flame retardant of the present invention.

[0030] The third object of the present invention is to disclose the use method of the above-mentioned flame retardant, which comprises the follow...

Embodiment 1

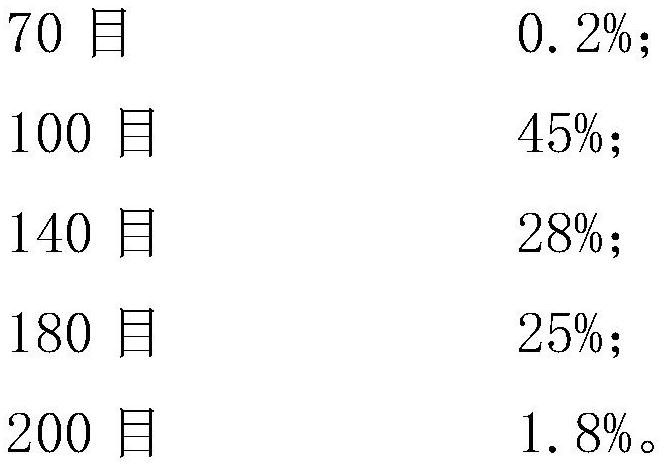

[0035] A flame retardant, the composition ratio is 100% potassium fluoroborate, and after ball milling for 1 hour, it is screened with a screen, and the flame retardant disclosed in this embodiment is prepared by remixing according to the particle size ratio. The particle size ratio is specifically:

[0036]

[0037] After measurement, the bulk density of the flame retardant disclosed in this example is 1.55g / cm 3 .

[0038] For the use method of the flame retardant disclosed in this embodiment, 2% by weight of the flame retardant is added to the foundry sand, and the 3D printing method completes the production of the sand mold, and the surface of the sand mold has no cracks and no veins.

[0039] The 3D printing sand mold made of the flame retardant disclosed in this embodiment is used for magnesium-aluminum alloy casting, and there is no combustion phenomenon during the pouring process, and the magnesium-aluminum alloy solution does not react with the sand mold.

Embodiment 2

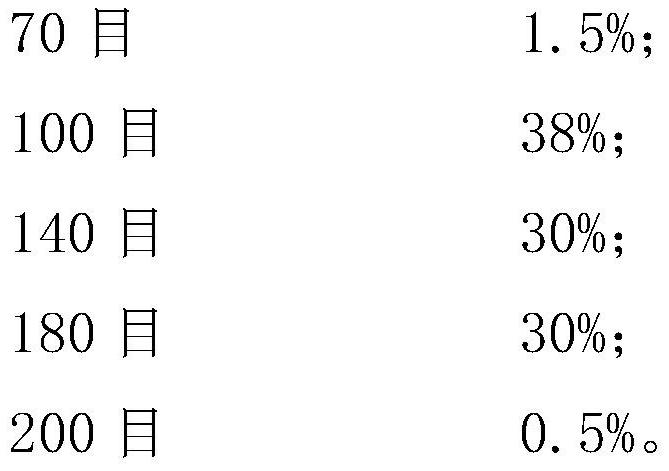

[0041] A flame retardant, the composition ratio is 40% sodium tetraborate, 30% potassium fluoroborate, 20% ammonium fluoroborate and 10% ammonium phosphate. After ball milling for 1 hour, use a screen to sieve, and remix according to the particle size ratio. The flame retardant disclosed in this embodiment is obtained, and the particle size ratio is specifically:

[0042]

[0043] After measurement, the bulk density of the flame retardant disclosed in this example is 1.55g / cm 3 .

[0044] For the use method of the flame retardant disclosed in this embodiment, 2% by weight of the flame retardant is added to the foundry sand, and the 3D printing method completes the production of the sand mold, and the surface of the sand mold has no cracks and no veins.

[0045] The 3D printing sand mold made of the flame retardant disclosed in this embodiment is used for magnesium-aluminum alloy casting, and there is no combustion phenomenon during the pouring process, and the magnesium-al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com