Silica sand for 3D printing and preparation method and application thereof

A 3D printing and silica sand technology, applied in the field of 3D printing materials, can solve the problems of large deviation of sand core strength, rough surface of sand core, and easy moisture of silica sand, etc., to achieve smooth sanding, improve surface quality, and improve smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

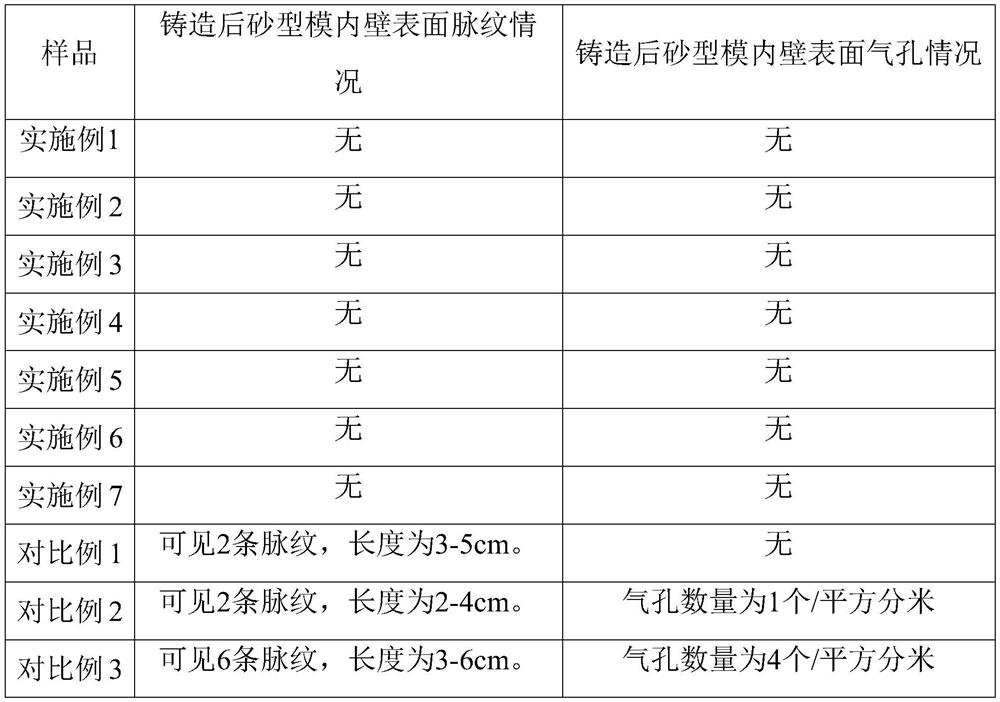

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing silica sand for 3D printing. The preparation method includes the following steps:

[0032] S1, Grinding: Grinding the raw silica sand until the angle coefficient is 1.3, wherein the silicon content of the raw silica sand is 99%;

[0033] S2, magnetic separation and drying: perform magnetic separation on the raw material silica sand, and carry out drying treatment at the same time, the drying temperature is 150°C;

[0034] S3, roasting: the raw silica sand was roasted at 900° C. for 3 hours, and then cooled in the furnace to obtain silica sand.

Embodiment 2

[0036] This embodiment provides a method for preparing silica sand for 3D printing. The preparation method includes the following steps:

[0037] S1, Grinding: Grinding the raw silica sand until the angle coefficient is 1.2, wherein the silicon content of the raw silica sand is 99.2%;

[0038] S2, magnetic separation and drying: perform magnetic separation on the raw material silica sand, and carry out drying treatment at the same time, the drying temperature is 160°C;

[0039] S3, roasting: the raw silica sand was roasted at 910° C. for 2.5 hours, and then cooled in the furnace to obtain silica sand.

Embodiment 3

[0041] This embodiment provides a method for preparing silica sand for 3D printing. The preparation method includes the following steps:

[0042] S1, Grinding: Grinding the raw silica sand until the angle coefficient is 1.2, wherein the silicon content of the raw silica sand is 99.5%;

[0043] S2, magnetic separation and drying: perform magnetic separation on the raw material silica sand, and carry out drying treatment at the same time, the drying temperature is 170°C;

[0044] S3, roasting: the raw silica sand was roasted at 920° C. for 2.5 hours, and then cooled in the furnace to obtain silica sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com