3D printing sand, high-temperature and cooling treatment process and application thereof

A processing technology and 3D printing technology, applied in the field of 3D printing materials, can solve problems such as affecting product quality, expansion and contraction, and increase in air volume of the mold, so as to reduce the probability of veining and pores, improve production efficiency, and improve surface quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

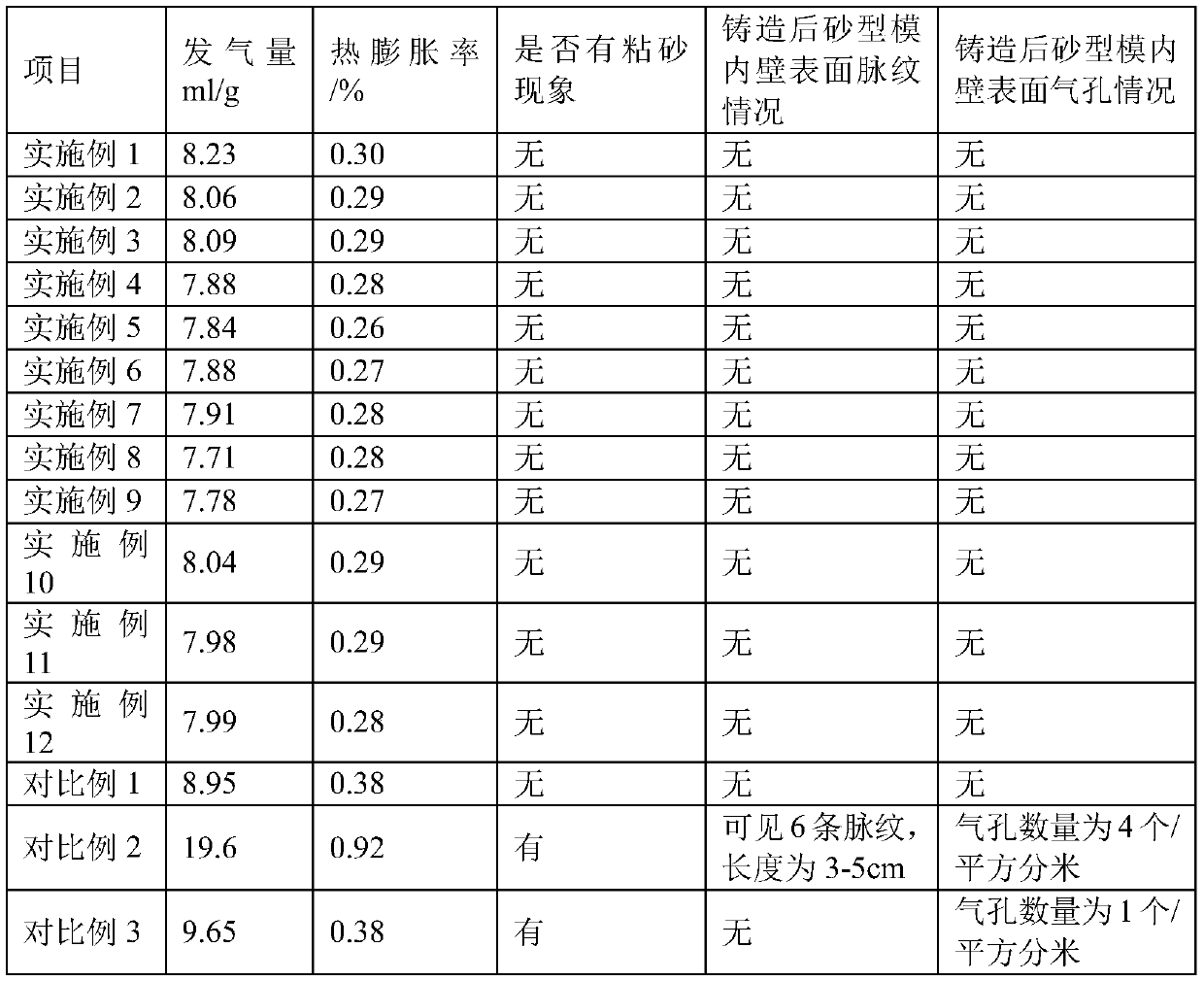

Examples

Embodiment 1

[0030] A 3D printing sand high temperature and cooling treatment process, the treatment process includes the following steps:

[0031] (1) High-temperature roasting treatment of natural silica sand; select natural silica sand with a particle size of 70 meshes, with a mud content of 0.17% and a silicon content of 99.4%, and transport this natural silica sand to a vertical roasting kiln. Roasting treatment, the treatment time is 90 minutes;

[0032] (2) Transport the natural silica sand obtained by the high temperature treatment into a cooling bed for cooling treatment so that the temperature drops to 50° C. to obtain printing sand.

Embodiment 2

[0034] A 3D printing sand high temperature and cooling treatment process, the treatment process includes the following steps:

[0035] (1) High-temperature roasting treatment of natural silica sand; select natural silica sand with a particle size of 120 meshes, which has a mud content of 0.14% and a silicon content of 99.6%, and transports this natural silica sand to a vertical roasting kiln. Roasting treatment, the treatment time is 95 minutes;

[0036] (2) Transport the natural silica sand obtained by the high temperature treatment into the cooling bed for cooling treatment, and lower the temperature to 70° C. to obtain the printing sand.

Embodiment 3

[0038] A 3D printing sand high temperature and cooling treatment process, the treatment process includes the following steps:

[0039] (1) High-temperature roasting treatment of natural silica sand; select natural silica sand with a particle size of 140 meshes, with a mud content of 0.15% and a silicon content of 99.6%, and transport the natural silica sand to a vertical roasting kiln. Roasting treatment, the treatment time is 100 minutes;

[0040] (2) Transport the natural silica sand obtained by the high temperature treatment into the cooling bed for cooling treatment, so that the temperature is lowered to 80° C., and the printing sand is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com