Processing method of pulp of dogwood fruit

A technology of cornus and cornus, which is applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, plant raw materials, etc., can solve the problem of low loganin content in cornus, reduce the loss of loganin, The operation process is easy to control and reduce the effect of mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

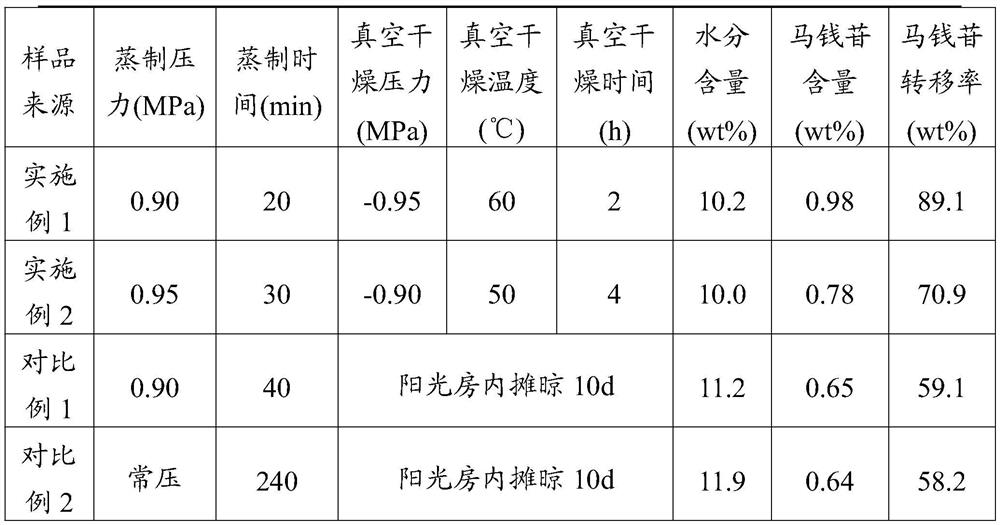

Embodiment 1

[0031] Taking the fresh dogwood fruit with a loganin content of 1.1 wt%, using a medicine moisturizing machine for high-pressure steaming after cleaning, the steaming pressure is 0.90 MPa, and the steaming time is 20min, to obtain the steamed dogwood fruit;

[0032] The steamed dogwood fruit is naturally cooled to room temperature (25° C.) to remove impurities and fruit pits to obtain clean dogwood flesh;

[0033] The clean mountain dogwood meat is vacuum-dried, the vacuum degree is -0.95 MPa, the drying temperature is 60° C., and the drying time is 2 hours, so as to obtain the finished mountain dogwood meat.

[0034] The processed mountain dogwood meat product is tested, and the result shows that the moisture content of the mountain dogwood meat product is 10.2wt%, and the loganin content is 0.98wt%. Loganin transfer rate (%) = loganin content in fresh dogwood fruit / loganin content in finished cornus meat × 100%, it can be seen from the calculation that the loganin transfer...

Embodiment 2

[0036] Taking the fresh dogwood fruit with a loganin content of 1.1 wt%, using a medicine moisturizing machine for high-pressure steaming after cleaning, the steaming pressure is 0.95MPa, and the steaming time is 30min, to obtain the steamed dogwood fruit;

[0037] The steamed dogwood fruit is naturally cooled to room temperature (25° C.) to remove impurities and fruit pits to obtain clean dogwood flesh;

[0038] The clean mountain dogwood meat is vacuum-dried, the vacuum degree is -0.90 MPa, the drying temperature is 50° C., and the drying time is 4 hours, so as to obtain the finished mountain dogwood meat.

[0039] The finished product of the processed mountain dogwood meat in this example was tested, and the results showed that the moisture content of the processed mountain dogwood meat product was 10.0 wt%, the loganin content was 0.78 wt%, and the loganin transfer rate was 70.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com