Ink direct-writing zinc ion hybrid miniature supercapacitor and preparation method and application thereof

A technology of supercapacitors and zinc ions, applied in the field of electrochemical energy storage, to achieve good rate performance and cycle stability, high energy density and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Zn(NO 3 ) 2 ·6H 2 ZIF-8 particles of O and 2-methylimidazole are mixed with PVP in a mass ratio of 1:(0.5-2) to obtain a material ZPC without pyrolysis. Its structure is as follows figure 1 shown.

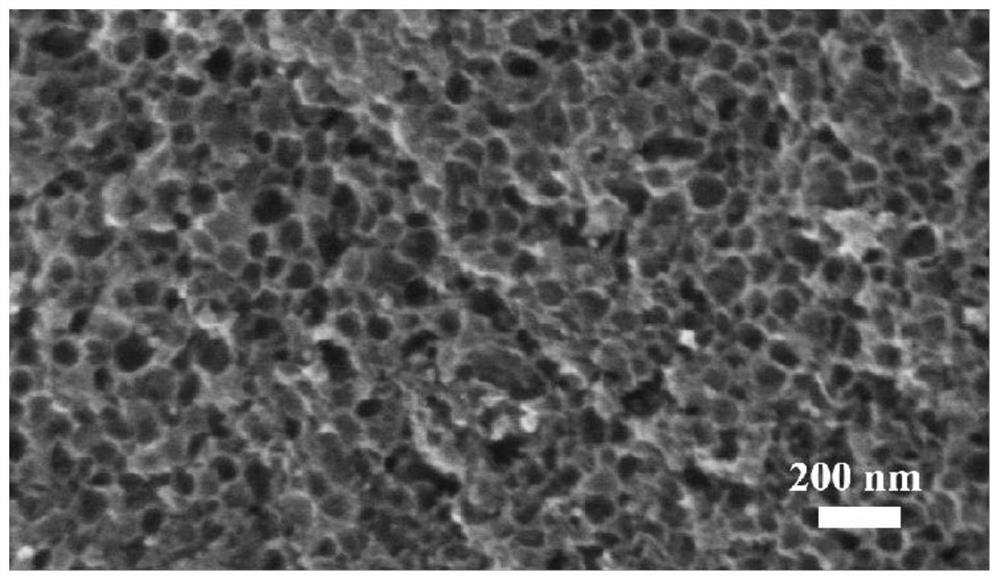

[0031] (2) Put the ZPC into a tube furnace under an argon atmosphere at a constant temperature of 700-850 °C for 2-4 hours, and after 1-3M HCl acid treatment, a porous material HCF is obtained, and its structure is as follows figure 2 shown.

[0032] (3) Mix the obtained HCF and KOH according to the mass ratio of 1:(1.5-5), stir and dissolve at 65-90 ° C and stir and dry, and then keep the tube furnace in an argon atmosphere at a constant temperature of 700-850 ° C for 2 -4h, the multi-layer porous carbon material PCF was obtained, and its structure was as follows image 3 shown.

[0033] (4) The obtained multi-layer porous carbon material, conductive carbon black, and polyvinylidene fluoride mass ratio range is (7-8.5): (1-1.5): (1:1.5) grinding in a mortar for 2...

Embodiment 2

[0037] (1) Zn(NO 3 ) 2 ·6H 2 The ZIF-8 particles of O and 2-methylimidazole were mixed with PVP in a mass ratio of 1:(1-3) to obtain ZPC without pyrolysis.

[0038] (2) Put the ZPC into a tube furnace under an argon atmosphere at a constant temperature of 600-950°C for 1.5-5h, and after being treated with 0.5-2M HCl acid, the porous material HCF is obtained.

[0039] (3) Mix the obtained HCF and KOH according to the mass ratio of 1:(2.5-4), stir and dissolve at 70-85 ° C and stir and dry, and then keep a constant temperature at 600-950 ° C in a tube furnace under an argon atmosphere for 1 -6h, multi-layer porous carbon material PCF was obtained.

[0040] (4) The obtained multi-layer porous carbon material, conductive carbon black, and polyvinylidene fluoride mass ratio range is (7-8): (2-1.5): (2-1.5) and grind in a mortar for 3-5h, get the positive electrode material ink;

[0041] (5) Disperse the conductive silver glue in N-methylpyrrolidone to ultrasonically prepare in...

Embodiment 3

[0044] (1) Zn(NO 3 ) 2 ·6H 2 ZIF-8 particles of O and 2-methylimidazole are mixed with PVP in a mass ratio of 1:(1-2) to obtain a material ZPC without pyrolysis. Its structure is as follows figure 1 shown.

[0045] (2) Put the ZPC into a tube furnace under an argon atmosphere at a constant temperature of 350-900° C. for 1-4 hours, and after being treated with 0.25-1.25M HCl acid, the porous material HCF is obtained.

[0046] (3) Mix the obtained HCF and KOH according to the mass ratio of 1:(1.5-4), stir and dissolve at 45-95 ° C and stir and dry, and then keep the tube furnace in an argon atmosphere at a constant temperature of 3.5 at 250-950 ° C -6.5h, multi-layer porous carbon material PCF was obtained.

[0047] (4) The obtained multi-layer porous carbon material, conductive carbon black, and polyvinylidene fluoride mass ratio range is (5.5-8.5): (1-3.5): (1-3.5) Grind in a mortar for 5-9h, get the positive electrode material ink;

[0048] (5) Disperse the conductive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com