Equipment and method for reducing drilling burrs

A technology of draping and equipment, which is applied in the manufacture of printed circuits, electrical components, and printed circuits. The effect of cloaking the front, reducing pressure, and reducing the feed speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

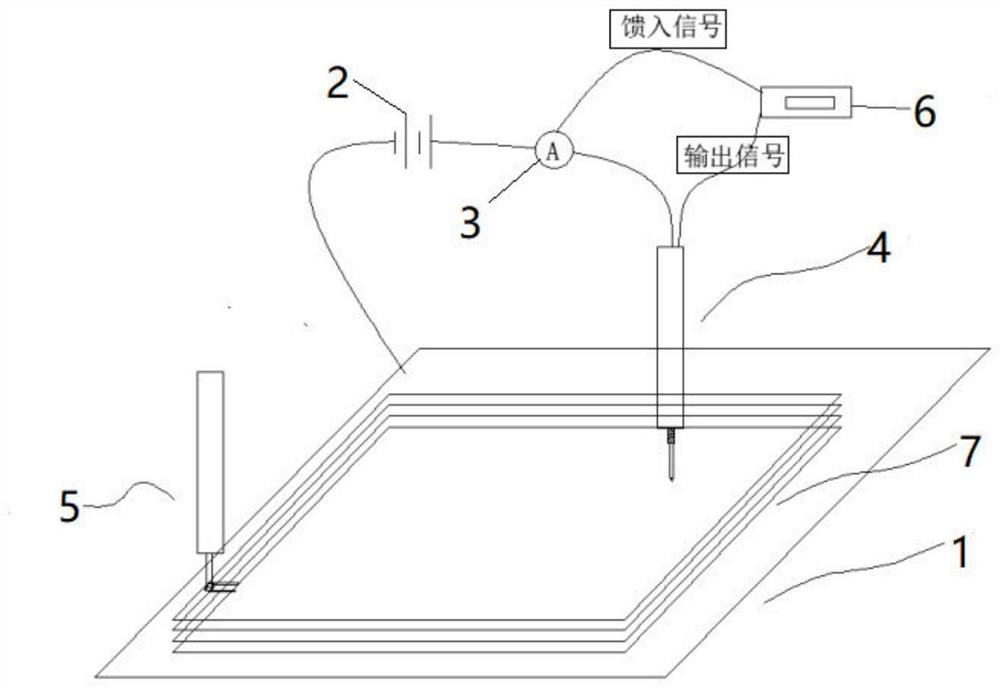

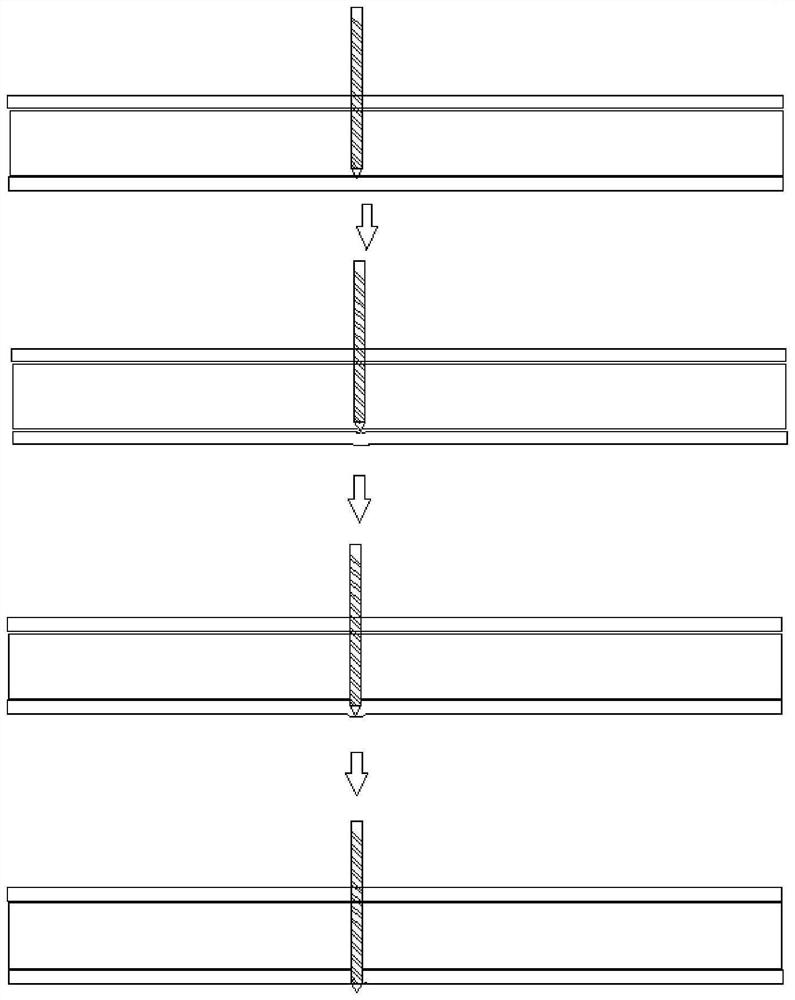

[0025] A device and method for reducing drilling burrs are realized through directional current conduction and PLC control. The equipment consists of a drilling rig with a conductive feedback system, a presser foot plate, a drill bit, an aluminum sheet, a backing plate and a PCB board; the PCB board placement method, from top to bottom, is the PCB board, the aluminum sheet, and the backing board. The drilling rig is connected to the aluminum sheet at the bottom of the PCB board through a conductor, and the aluminum sheet is connected to the bottom copper foil of the PCB. When drilling to the bottom according to the normal drilling parameters, the tip angle of the drill tool contacts the bottom copper foil and the drill tool forms a loop, which is fed back to the PLC system to slow down or stop the feed speed of the drill spindle, keep the speed unchanged, and continue to feed by inertia. . Make the copper foil and the base material in a small feeding force, reduce the single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com