Multi-mode aggregation-induced fluorescence immunochromatography test paper and preparation method thereof

A technology with aggregation-induced fluorescence and fluorescence characteristics, applied in the field of rapid immunoassay, it can solve problems such as limitations, and achieve the effects of stable markers, controllable conditions, and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

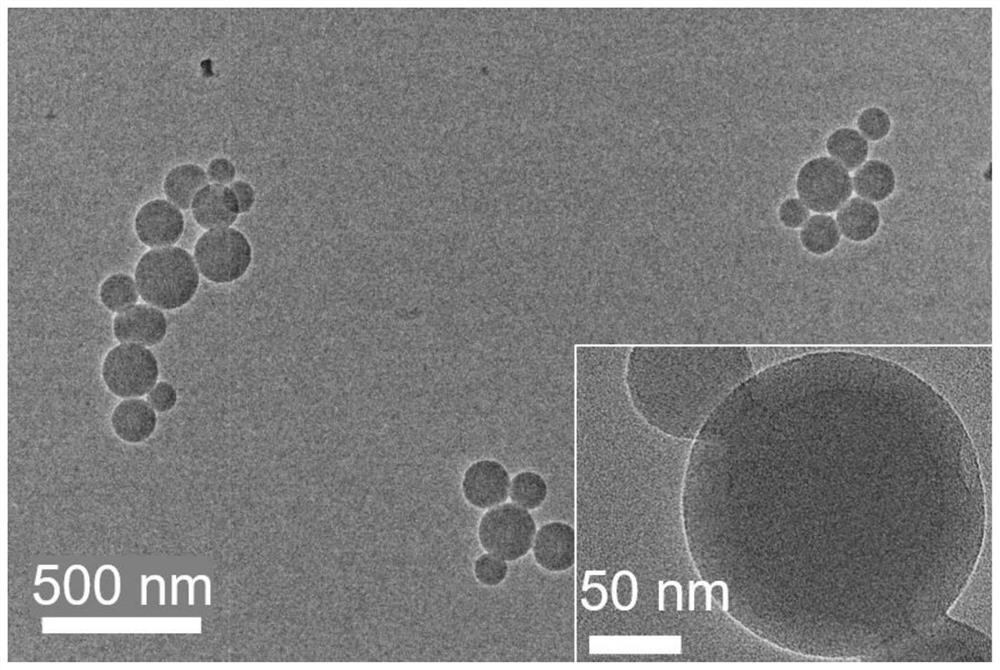

[0034] Example 1: Preparation of aggregation-induced fluorescent particles and method for labeling C-reactive protein antibody:

[0035] A. Preparation of oil phase components: Disperse tetrastyrene-based AIE derivatives and polystyrene-maleic anhydride copolymer (molecular weight 1900, purchased from Sigma-Aldrich) in chloroform solution, and tetrastyrene-based AIE derivatives The concentration is 10 mg / mL, and the concentration of the polymer is 10 mg / mL;

[0036] B. Preparation of water phase components: Sodium dodecyl sulfonate and Triton X-100 are prepared into an aqueous solution, the mass concentration of sodium dodecyl sulfonate is 0.1%, and the mass concentration of Triton X-100 is 0.1%. is 0.5%;

[0037] C. Add the oil phase to the aqueous phase solution, stir magnetically until it is uniform, and then use an ultrasonic crusher to perform ultrasonic treatment on the mixed solution for 2 minutes to obtain a uniform and stable microemulsion;

[0038] D. At room tempera...

Embodiment 2

[0043] Example 2: Preparation of aggregation-induced fluorescent particles and method for labeling goat anti-rabbit immunoglobulin (IgG) antibody:

[0044] A. Preparation of oil phase components: Disperse tetrastyrene AIE derivatives and polystyrene-acrylic acid copolymer (molecular weight 37000, purchased from Sigma-Aldrich) in chloroform solution, the concentration of tetrastyrene AIE derivatives is 10mg / mL, the concentration of the polymer is 10mg / mL;

[0045] B, preparation water phase component, is mixed with sodium dodecyl sulfonate into aqueous solution, and the mass concentration of sodium dodecyl sulfonate is 0.5%;

[0046] C. Add the oil phase to the aqueous phase solution, stir magnetically until it is uniform, and then use an ultrasonic breaker to perform ultrasonic treatment on the mixed solution for 5 minutes to obtain a uniform and stable microemulsion;

[0047] D. At room temperature, the microemulsion was placed in an open container, and under magnetic stirri...

Embodiment 3

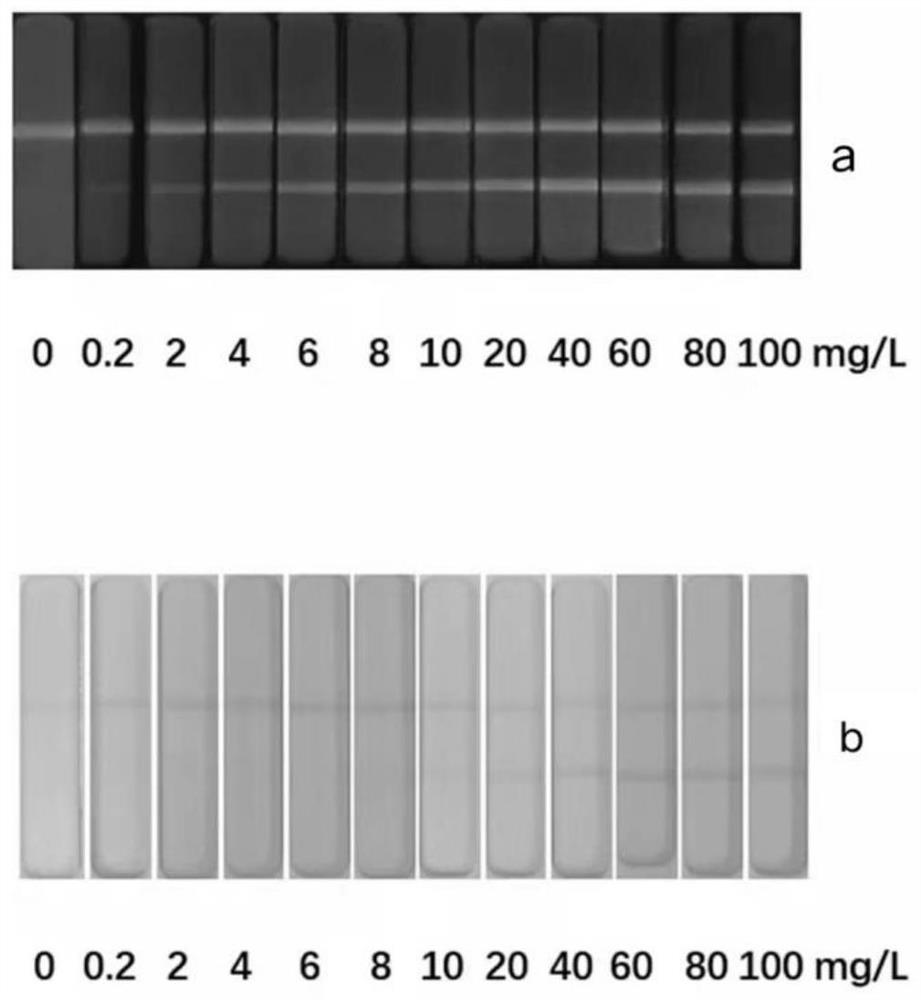

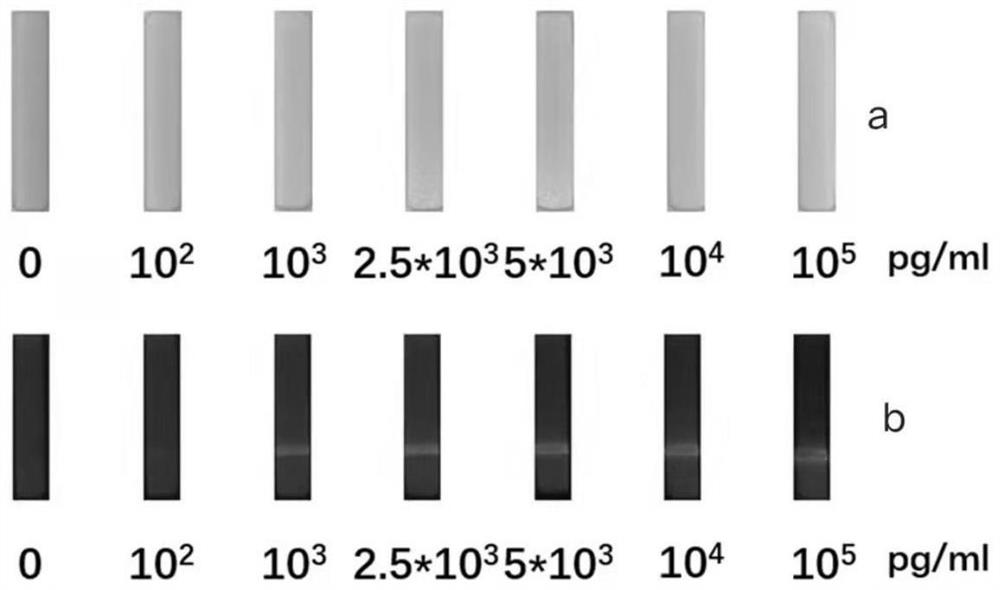

[0052] Example 3: Detection of C-reactive protein samples

[0053] Aggregation-inducing fluorescent particles labeled with C-reactive protein antibody in Example 1 (ie, aggregation-inducing fluorescent particles-C-reactive protein antibody complexes) and goat anti-rabbit IgG antibody-labeled aggregation-inducing particles in Example 2 (ie, aggregation-induced fluorescent particles) were used. Fluorescent particle-goat anti-rabbit IgG antibody complex) to prepare highly sensitive C-reactive protein aggregation-induced fluorescent particle multimodal immunochromatographic test paper, and the test paper production steps are as follows:

[0054] The aggregation-induced fluorescent particle-C-reactive protein antibody complex and the aggregation-induced fluorescent particle-goat anti-rabbit IgG antibody complex were coated on the coupling pad for use; the C-reaction was adjusted with phosphate buffered saline (PBS), respectively The concentration of another strain of protein and an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com