Method for preparing oil product through synthesis gas hydrogenation

A synthesis gas and hydrogen preparation technology, which is applied in the preparation of liquid hydrocarbon mixtures, chemical instruments and methods, and the petroleum industry. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

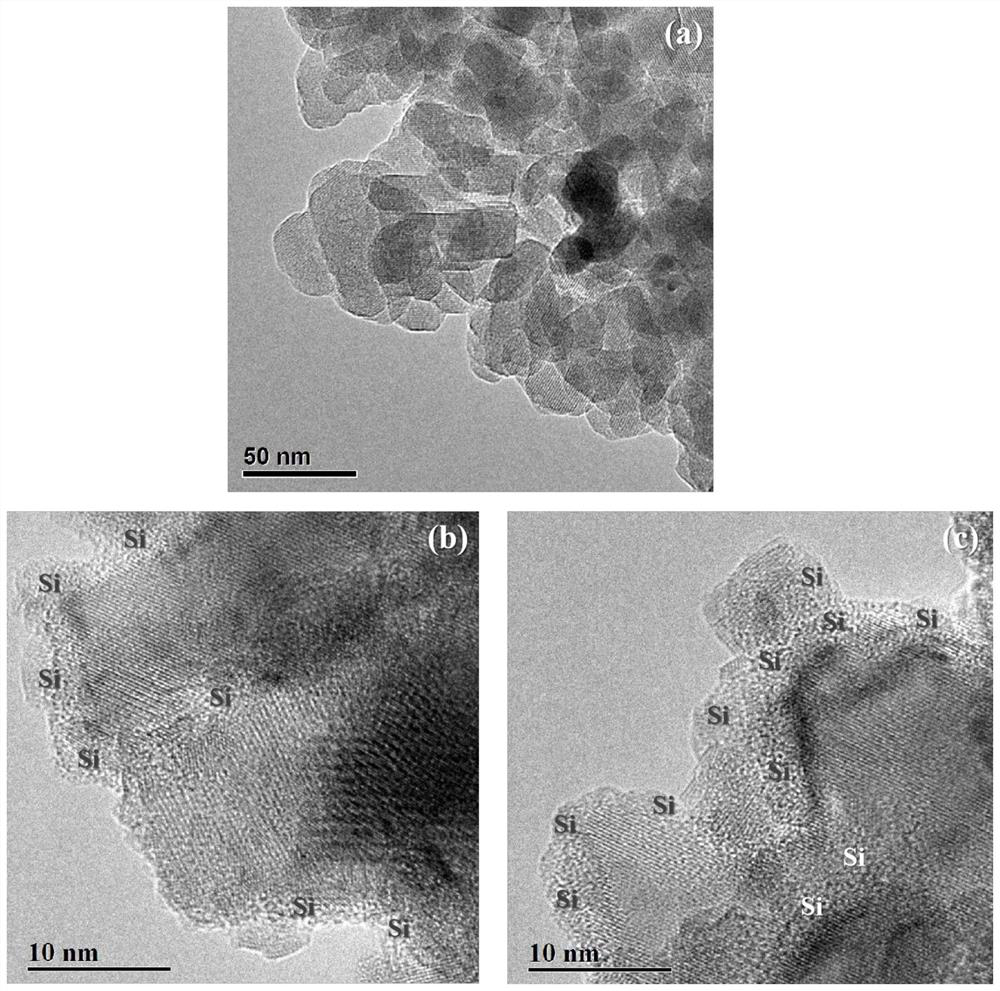

Image

Examples

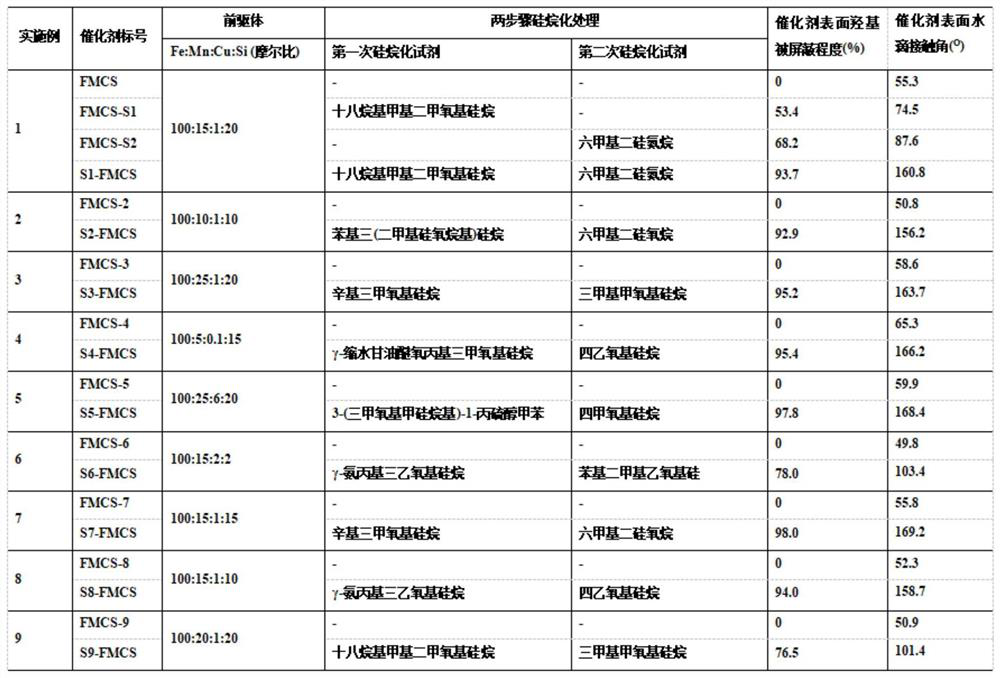

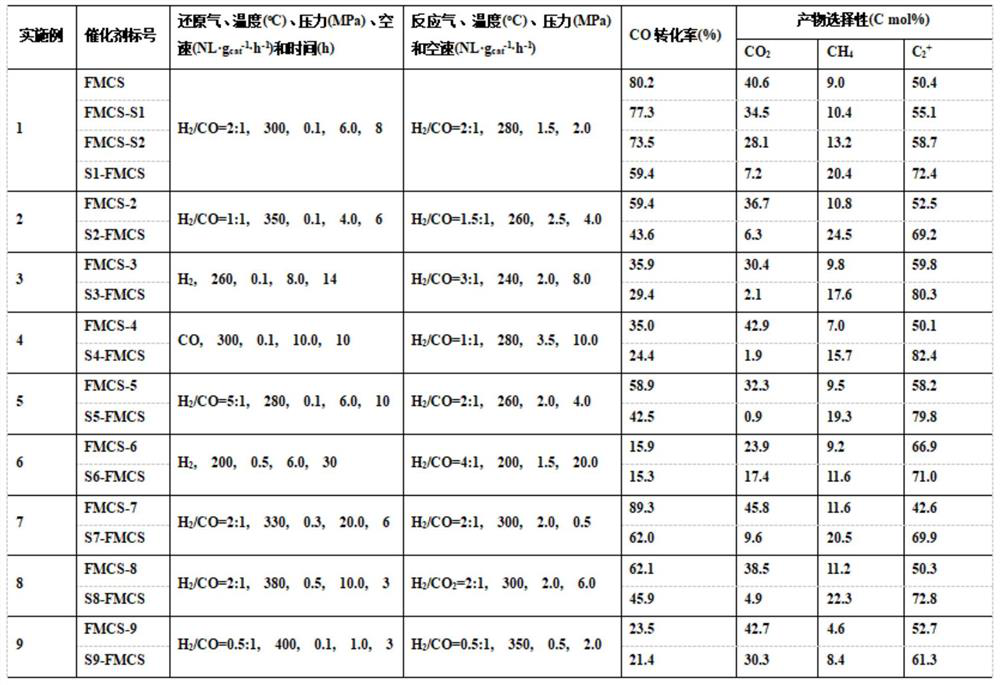

Embodiment 1

[0045]Preparation of iron-based precursors: 1) Dissolving iron nitrate, manganese nitrate and copper nitrate in water to obtain solution 1, in which the molar ratio of Fe:Mn:Cu is 100:15:1; Fe, Mn and Cu metal ions are The total molar concentration in the water is 3.0mol / L; 2) Prepare an aqueous ammonia solution, NH 4 + 3) After preheating solution 1, ammonia solution and ethyl orthosilicate to 50°C, carry out co-current precipitation under stirring conditions, keep the temperature at 50°C and pH value of 7 to obtain a precipitation solution , where the molar ratio of Fe:Si is 100:20; 4) The precipitation solution is aged with stirring for 3h, filtered, washed, and dried at 300°C for 5h to obtain the precursor, which is marked as FMCS-1.

[0046] Silanation treatment of iron-based precursor: 1) Mix 4g of FMCS-1 and 100mL of toluene in a 250ml double-necked round-bottom flask, add 10g of octadecylmethyldimethoxysilane, and at 120°C in an air atmosphere and mechanical stirring...

Embodiment 2

[0055] Preparation of iron-based precursors: 1) Dissolving iron nitrate, manganese nitrate and copper nitrate in water to obtain solution 1, wherein the molar ratio of Fe:Mn:Cu is 100:10:1; Fe, Mn and Cu metal ions are The total molar concentration in the water is 2.0mol / L; 2) Prepare an aqueous ammonia solution, NH 4 + 3) After preheating solution 1, ammonia solution and ethyl orthosilicate to 40°C, carry out co-current precipitation under stirring conditions, keep the temperature at 40°C and pH value of 7 to obtain a precipitation solution , where the molar ratio of Fe:Si is 100:10; 4) The precipitation solution is aged with stirring for 1 h, filtered, washed, and dried at 400 °C for 5 h to obtain the precursor, which is marked as FMCS-2.

[0056] Silanation treatment of iron-based precursor: 1) Mix 4g of FMCS-2 and 80mL of toluene in a 250ml double-necked round-bottom flask, add 10g of phenyltris(dimethylsiloxane)silane, and at 120°C, Silanation treatment was carried out ...

Embodiment 3

[0062] Preparation of iron-based precursors: 1) Dissolving iron nitrate, manganese nitrate and copper nitrate in water to obtain solution 1, wherein the molar ratio of Fe:Mn:Cu is 100:25:1; Fe, Mn and Cu metal ions are The total molar concentration in the water is 4.5mol / L; 2) Prepare an aqueous ammonia solution, NH 4 + 3) After preheating solution 1, ammonia solution and ethyl orthosilicate to 55°C, carry out co-current precipitation under stirring conditions, keep the temperature at 55°C and pH value of 8 to obtain a precipitation solution , where the molar ratio of Fe:Si is 100:20; 4) The precipitation solution is aged by stirring for 2h, filtered, washed, and dried at 300°C for 3h to obtain the precursor, which is marked as FMCS-3.

[0063] Silanation treatment of iron-based precursor: 1) Mix 4g of FMCS-3 and 240mL of cyclohexane in a 500ml double-neck round-bottom flask, add 32g of octyltrimethoxysilane, and stir at 110°C under nitrogen atmosphere and mechanical stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com