Dental bone material for in-vitro collagen demineralization

A bone and demineralization technology, applied in the field of biomedical engineering, can solve the problem of low mechanical strength, achieve the effect of short processing time, good mechanical strength, and promote cell adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

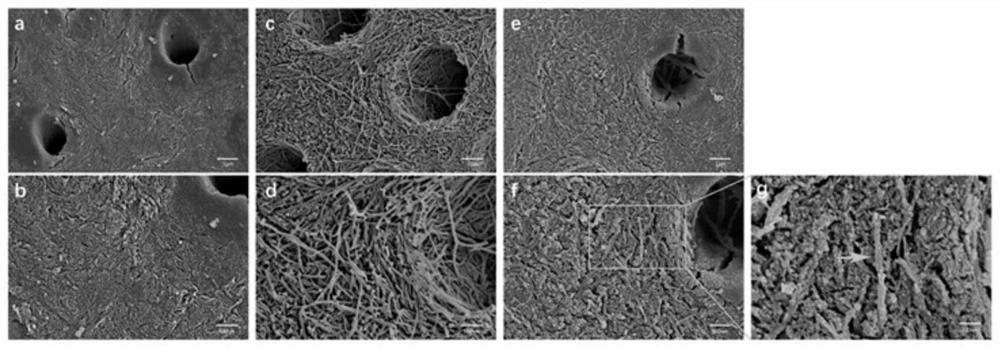

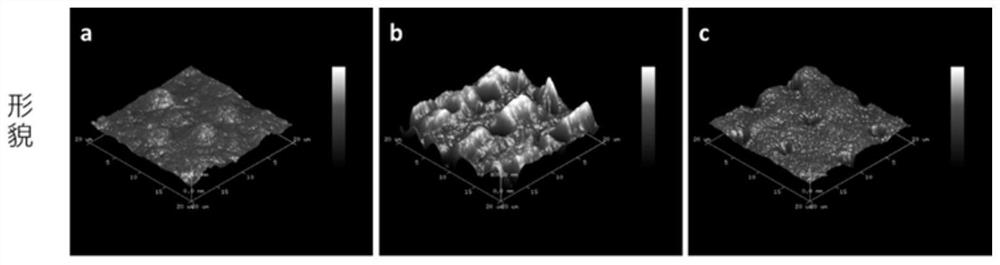

Image

Examples

Embodiment 1

[0039] S1. Take fresh human teeth, ultrasonically clean them with deionized water for 3 times, filter the water, add disinfectant (75% ethanol), soak for 15 minutes at room temperature, filter out the solution, soak in sterile deionized water for 1 hour , ultrasonic cleaning for 5 minutes, repeat the above soaking ultrasonic cleaning 3 times;

[0040] S2. Use mechanical methods to remove the enamel of the tooth, open the pulp, and extract the pulp tissue to obtain a dentin matrix-based material A;

[0041] S3. Use an electric grinder to pulverize material A, and collect dentin powder with a particle size of 0.2-0.8 mm to obtain material B;

[0042] S4. Soak material B in sterile phosphate buffered saline (PBS) for ultrasonic cleaning, replace the liquid every 10 minutes for a total of 30 minutes of cleaning, and remove the cleaning solution to obtain material C;

[0043] S5. Add material C into a 15% wt PAAN (Mw=225kDa) sodium polyacrylate aqueous solution, stir for 12 hours,...

Embodiment 2

[0047]S1. Take fresh human teeth, ultrasonically clean them with deionized water for 3 times, filter the water, add disinfectant (75% ethanol), soak for 15 minutes at room temperature, filter out the solution, soak in sterile deionized water for 1 hour , ultrasonic cleaning for 5 minutes, repeat the above soaking ultrasonic cleaning 3 times;

[0048] S2. Use mechanical methods to remove the enamel of the tooth, open the pulp, and extract the pulp tissue to obtain a dentin matrix-based material A;

[0049] S3. Use a slow-speed saw to cut material A to obtain a 2×2×1 mm cube-shaped dentin sheet material B;

[0050] S4. Soak material B in sterile phosphate buffered saline (PBS) for ultrasonic cleaning, replace the liquid every 10 minutes for a total of 30 minutes of cleaning, and remove the cleaning solution to obtain material C;

[0051] S5. Add material C into 15% wt PAAN (Mw=225kDa) sodium polyacrylate aqueous solution, stir for 24 hours, remove the solution, then inject ster...

Embodiment 3

[0055] The sodium polyacrylate involved in S5 in Example 1 was replaced with carboxymethyl chitosan, and the others were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com