Acrylate table printing gravure ink and preparation method thereof

An acrylic and gravure ink technology, applied in inks, chemical instruments and methods, transportation and packaging, etc., can solve problems such as insufficient gloss, affect printing effect, poor adhesion, etc., to improve stirring efficiency and mixing uniformity, Improves adhesion and gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

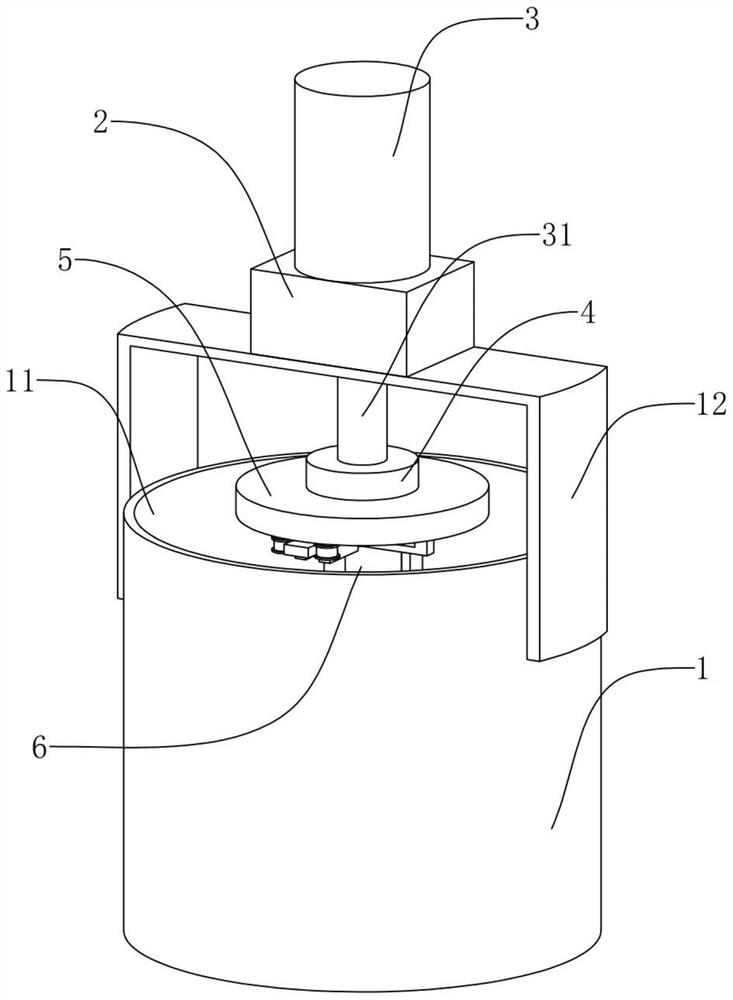

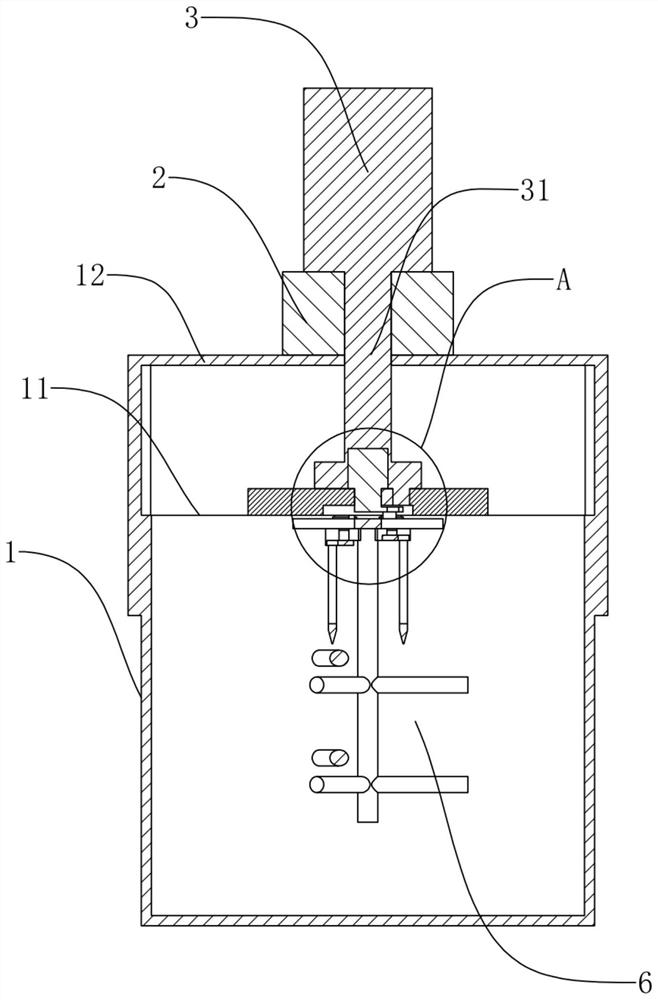

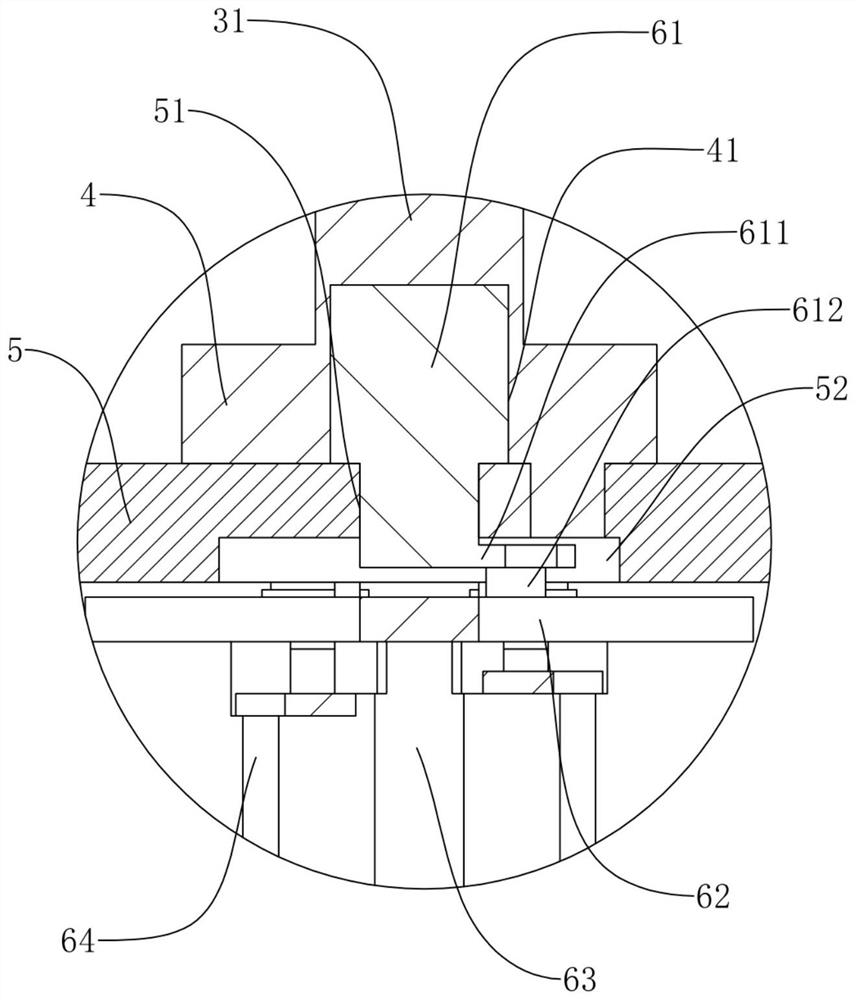

Image

Examples

Embodiment 1

[0045] An acrylic gravure ink for surface printing includes a blend group and a dilution group in a ratio of 5:1 by weight.

[0046] Wherein, the blend group comprises by weight 28 parts of acrylate emulsion, 16 parts of methylcyclopentadiene dimer, 15 parts of color paste, 6 parts of antioxidant, 3 parts of penetrant, 2.0 parts of dispersant, 1.0 part of photoinitiator and 0.6 part of polyacrylamine hydrochloride.

[0047] And the antioxidants are ditetradecyl alcohol ester, tert-butyl-p-cresol and dihydroquinoline, and the mass percentage of the ditetradecyl alcohol ester in the antioxidant is 60%. The penetrants were polyethylene glycol ethers, sodium alkyl succinate sulfonate, and sulfated castor oil. The dispersant is zinc stearate. The photoinitiator was diphenyl-(2,4,6-trimethylbenzoyl)phosphonium oxide.

[0048]Meanwhile, the dilution group included toluene, isopropanol, ethyl acetate and ethanol in a ratio of 5:3:1:1 by weight.

[0049] Therefore, the acrylic grav...

Embodiment 2

[0057] The difference between Example 2 and Example 1 is that the acrylic surface printing gravure ink in Example 2 includes a blend group and a dilution group in a ratio of 5:2 by weight.

[0058] Wherein, the blend group comprises by weight 32 parts of acrylate emulsion, 21 parts of methylcyclopentadiene dimer, 17 parts of color paste, 8 parts of antioxidant, 3.5 parts of penetrant, 2.3 parts of dispersant, 1.2 parts of photoinitiator and 0.7 parts of polyacrylamine hydrochloride.

[0059] And the antioxidants are ditetradecyl alcohol ester and 2,6-tertiary butyl-4-methylphenol, and the mass percentage of the ditetradecyl alcohol ester in the antioxidant is 80%. The penetrant is an alkylphenol polyoxyethylene ether. The dispersing agent is stearic acid monoglyceride and bisphenol-A polyoxyethylene ether. The photoinitiators were butyl benzoin and isopropylthioxanthone.

[0060] Meanwhile, the dilution group included toluene, isopropanol, ethyl acetate, and ethanol in a ra...

Embodiment 3

[0062] The difference between Example 3 and Example 1 is that the acrylic surface printing gravure ink in Example 3 includes a blend group and a dilution group in a ratio of 5:3 by weight.

[0063] Wherein, the blend group comprises by weight 36 parts of acrylate emulsion, 26 parts of methylcyclopentadiene dimer, 18 parts of color paste, 10 parts of antioxidant, 4 parts of penetrant, 2.6 parts of dispersant, 1.4 parts of photoinitiator and 0.8 parts of polyacrylamine hydrochloride.

[0064] And the antioxidants are ditetradecyl alcohol ester, tert-butyl-p-cresol and 2,6-tertiary butyl-4-methylphenol, and the ditetradecyl alcohol ester accounts for the antioxidant mass percentage is 85%. The penetrant is at least one of polyethylene glycol ether, polycarboxylate ether, alkylphenol polyoxyethylene ether, sodium alkyl succinate sulfonate and sulfated castor oil. The dispersing agents are monoglyceryl stearate, zinc stearate, polyethylene glycol and bisphenol-A polyoxyethylene e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com