Room-temperature self-repairing polyurethane based on multiple self-repairing units and preparation method thereof

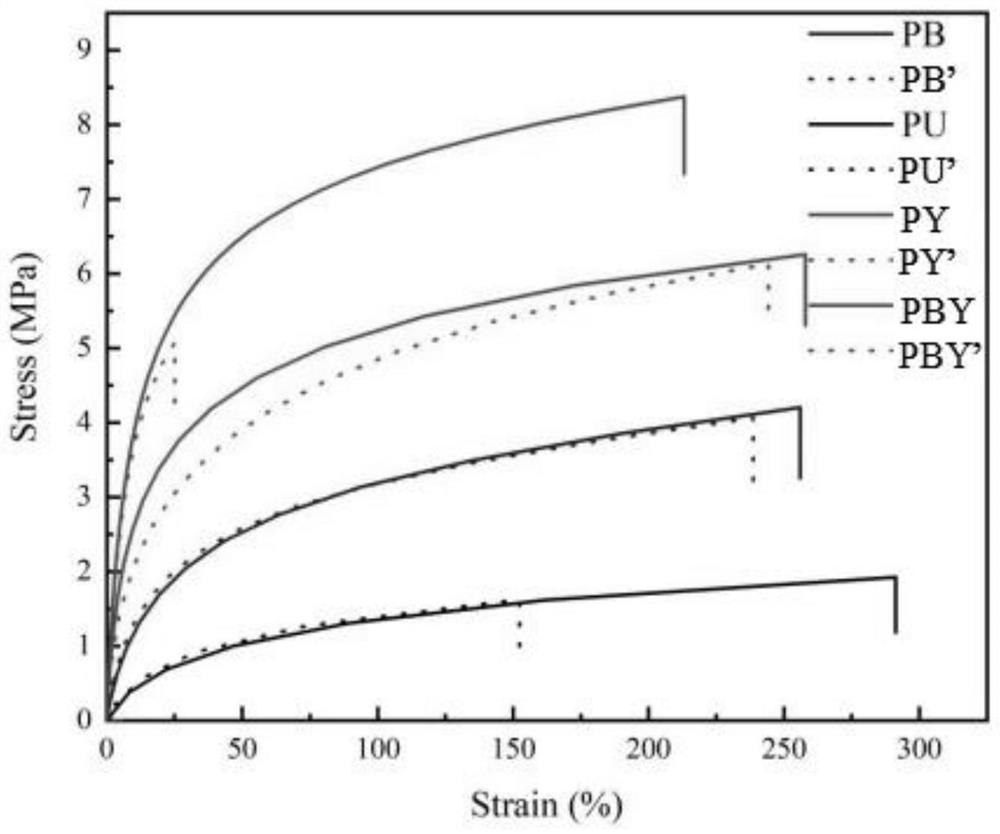

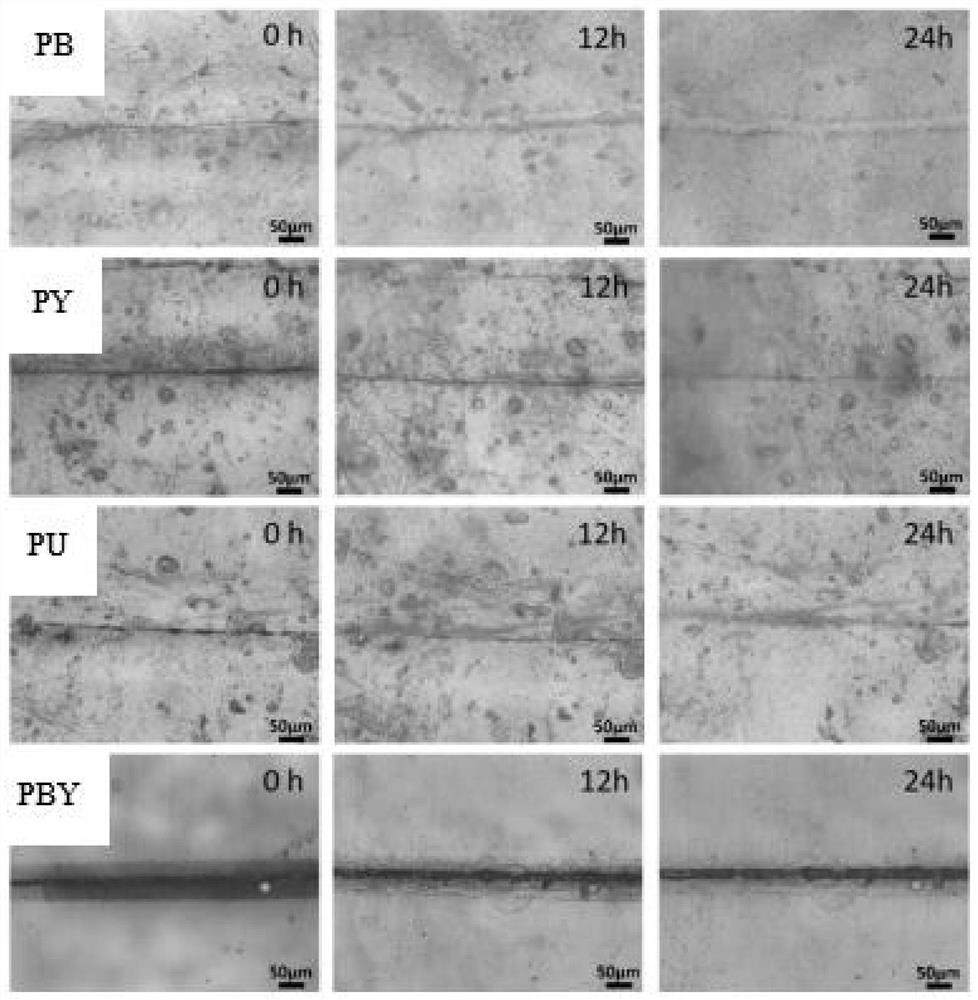

A self-healing and polyurethane technology, which is applied in the field of polyurethane and its preparation based on multiple self-healing units at room temperature self-healing, can solve the problems of poor self-healing ability under mild conditions, poor mechanical properties, low service life and functional reliability, and achieve Good mechanical properties, improved mechanical properties, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a preparation method of polyurethane self-repairing at room temperature based on multiple self-repairing units, comprising the following steps:

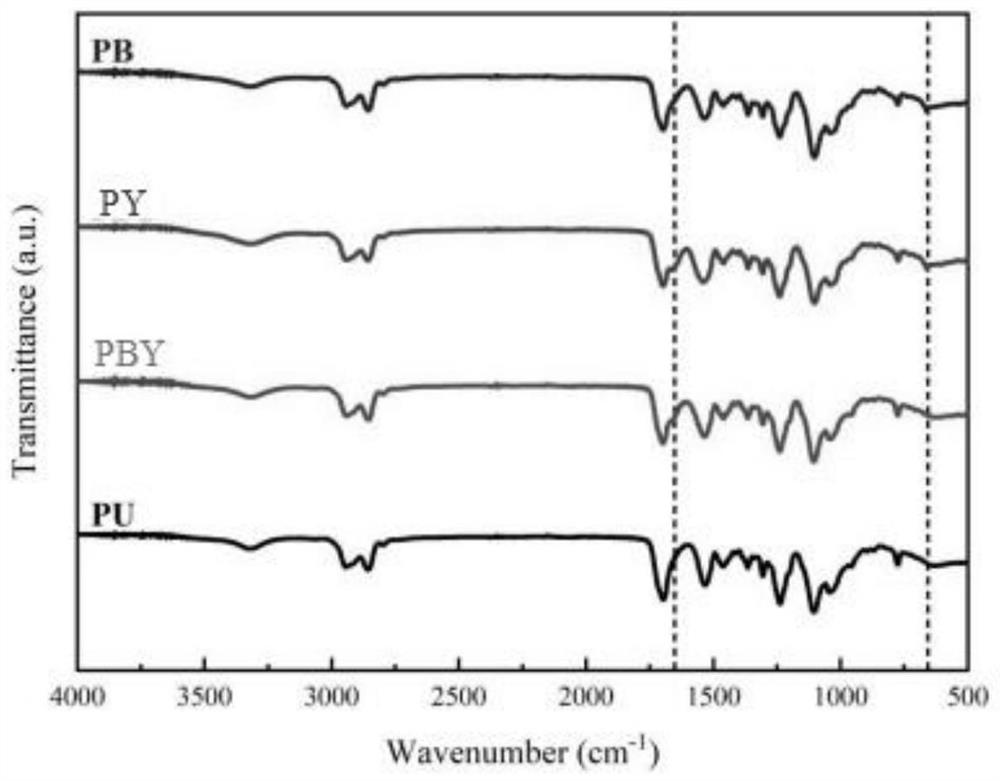

[0038] 1) mixing polytetrahydrofuran, 5-(2-hydroxyethyl)-6-methyl-2-aminouracil, and a solvent, and carrying out a dehumidification and impurity removal reaction to obtain a first mixture;

[0039] 2) mixing the first mixture, diisocyanate and a catalyst, and carrying out a catalytic reaction to obtain an isocyanate-terminated prepolymer;

[0040] 3) react after mixing the isocyanate-terminated prepolymer, 2,2-bis-methylolpropionic acid and diol to obtain a linear isocyanate-terminated polymer;

[0041] 4) mixing the linear isocyanate-terminated polymer with dihydroxy borate, and reacting to obtain a second mixture;

[0042] 5) The second mixture and the hydrophilic agent are mixed and reacted, and then end-capping, phase inversion, and curing reactions are performed in sequence to obtain a polyurethane f...

Embodiment 1

[0076] Preparation of 5-(2-hydroxyethyl)-6-methyl-2-aminouracil:

[0077] 1) 2-amino-4-hydroxy-6-methylpyrimidine (40mmol) and hexamethylene diisocyanate (240mmol) were reacted at 100°C for 20h, the reaction product was washed three times with solvent petroleum ether and then placed in an oven at 60°C Dry for 2h, and grind 3 times during this period;

[0078] 2) Dissolve the product (50 mmol) obtained in step 1) and 2-amino-1,3-propanediol (63.7 mmol) in solvent N,N-dimethylformamide, react at 100° C. for 2 h, add petroleum ether and ethyl acetate. 100 mL of mixed solution of ester (the molar ratio of petroleum ether and ethyl acetate is 1:1) precipitates the product, and then washes with acetone for 2 to 3 times after suction filtration. Take out the grind and keep it sealed.

Embodiment 2

[0080] Preparation of dihydroxyborate:

[0081] Terephthalic diboronic acid (25 mmol) and 1,2,6-hexanetriol (55 mmol) were dissolved in 100 mL of tetrahydrofuran, and anhydrous magnesium sulfate (10 g) was added to remove the water produced by the reaction. After reacting at room temperature for 24 h, filter, Finally, the filtrate was washed twice with n-hexane to obtain dihydroxyborate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com