Polyamide composite reverse osmosis membrane repairing method

A technology of reverse osmosis membrane and repair method, which is applied in the field of polyamide composite reverse osmosis membrane repair, can solve problems such as chemical modification of old and inferior membrane surface repair, waste reverse osmosis membrane originals, etc. Improves sodium ion osmotic resistance and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The performance-deteriorated polyamide film was fixed in a Teflon frame with an inner frame size of 10 × 20 cm, and placed for use. Concentrated hydrochloric acid was added dropwise to deionized water to prepare an aqueous hydrochloric acid solution with pH=1.02. Weigh 0.18 g of solid sodium nitrite in a beaker with a stirring magnet, pour into a pH=1.02 hydrochloric acid solution to a total mass of 60.0 g, and prepare an aqueous solution of sodium nitrite with a concentration of 0.3 wt%. Stir on a magnetic stirrer for 30s, and prepare the diazotization reagent. Pour the diazotization reagent onto the membrane surface, let it stand for 10 min at room temperature of 20°C, pour off the diazotization reagent on the membrane surface, put the polyamide membrane with deteriorated performance after the surface diazotization into ionized water, and soak it in ionized water. Put it in a container with ultraviolet light for 3 hours, and finally wash it with deionized water and s...

Embodiment 2

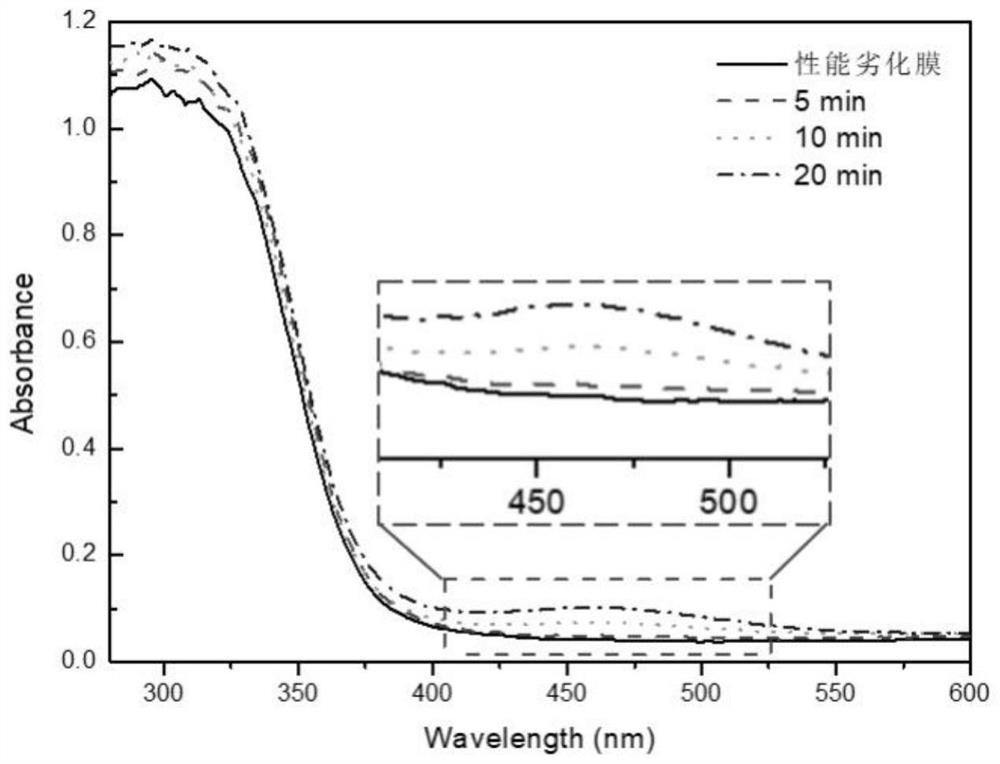

[0042] Take three polyamide films with deteriorated performance, respectively fix them in a PTFE frame with an inner frame size of 10×20 cm, and place them for use. Concentrated hydrochloric acid was added dropwise to deionized water to prepare an aqueous hydrochloric acid solution with pH=3.00. Weigh 0.15 g of solid sodium nitrite into a beaker with a stirring magnet, pour into a pH=3.00 hydrochloric acid solution to a total mass of 150.0 g, and prepare an aqueous solution of sodium nitrite with a concentration of 0.1 wt%. Stir on a magnetic stirrer for 30s, and prepare the diazotization reagent. Pour the diazotization reagent on the 3 membrane surfaces on average, and let stand for 5, 10 and 20 minutes at room temperature and 20°C, respectively. After the diazotization reagent is poured off the membrane surface, the performance of the polyamide after the surface diazotization is degraded. The membrane was soaked in ionized water, placed in a container with ultraviolet light...

Embodiment 3-4

[0046] Except that the pH was changed to the pH described in Table 1, the other procedures were the same as those in Example 1.

[0047] [Table 1]

[0048] pH Average water flux (l / m 2 .h)

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com