Method for synthesizing porphyrin-based two-dimensional metal organic framework nanosheet array on zinc substrate and battery

A metal-organic framework and nanosheet array technology, which is applied in the field of electrochemical power supply, can solve the problems such as the inability to adjust the wall thickness and sheet size of MOF, the incompact deposition of zinc metal, and the inapplicability to the battery field, so as to ensure ion transport, The synthesis method is simple, and the preparation process is green and pollution-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

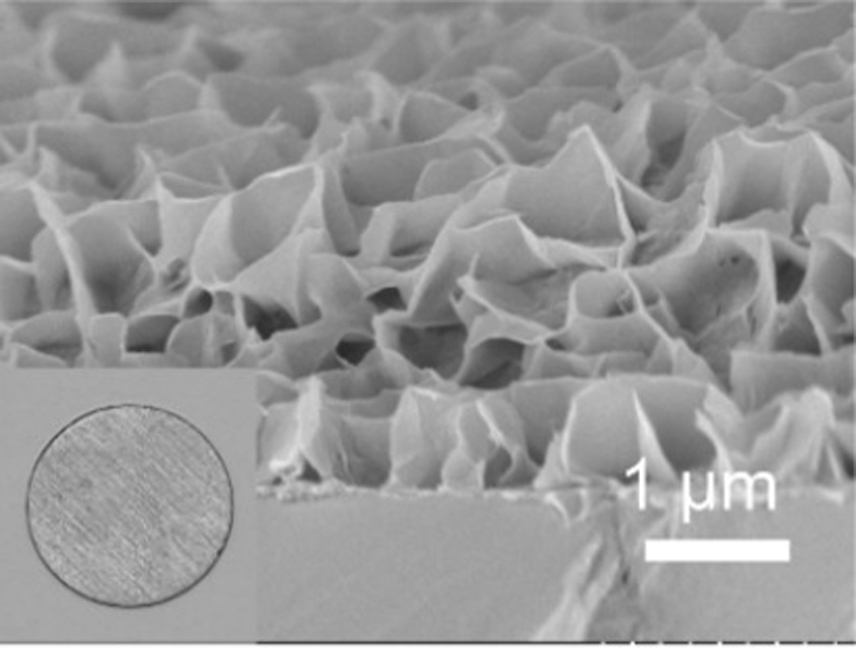

[0040] (1) Preparation of porphyrin-based Zn-TCPP nanosheet arrays.

[0041] A method for synthesizing a porphyrin-based two-dimensional metal-organic framework (MOF) nanosheet array on a zinc substrate, characterized in that the preparation process at least comprises the following steps:

[0042] The first step is to prepare the solution: at room temperature, weigh a certain amount of 4,4,4,4-(porphyrin-5,10,15,20-tetraformyl)tetrakis(benzoic acid) (TCPP) and dissolve it in In dimethylformamide / ethanol mixed solvent, ultrasonically dispersed, the concentration is 2 mgml -1 , to obtain the precursor solution.

[0043] The second step is to polish the zinc sheet with 600-1000 mesh sandpaper to remove the oxide layer on the surface;

[0044] In the third step, the precursor solution and the polished zinc substrate are put into a reaction kettle for reaction at a reaction temperature of 60°C and a time of 5 minutes to obtain a two-dimensional Zn-TCPP array;

[0045] In the fou...

Embodiment 2

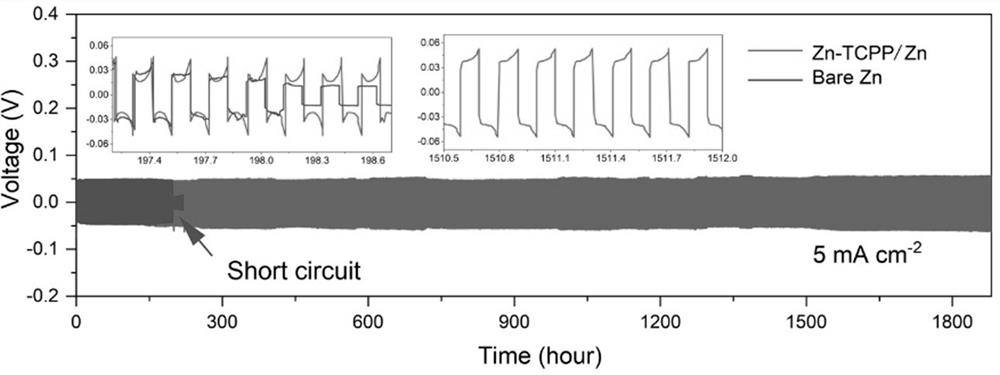

[0051] The difference from implementation 1 is that the mixed solvent in the first step is a mixture of dimethylformamide and methanol, the solvent in the third step is water, and the reaction time in the third step is 10 minutes. The height of the grown two-dimensional Zn-TCPP array was extended to about 1 μm, no dendrites were generated in the zinc deposition test, and the deposition method was U-shaped.

[0052] The rest are the same as in Embodiment 1, and are not repeated here.

Embodiment 3

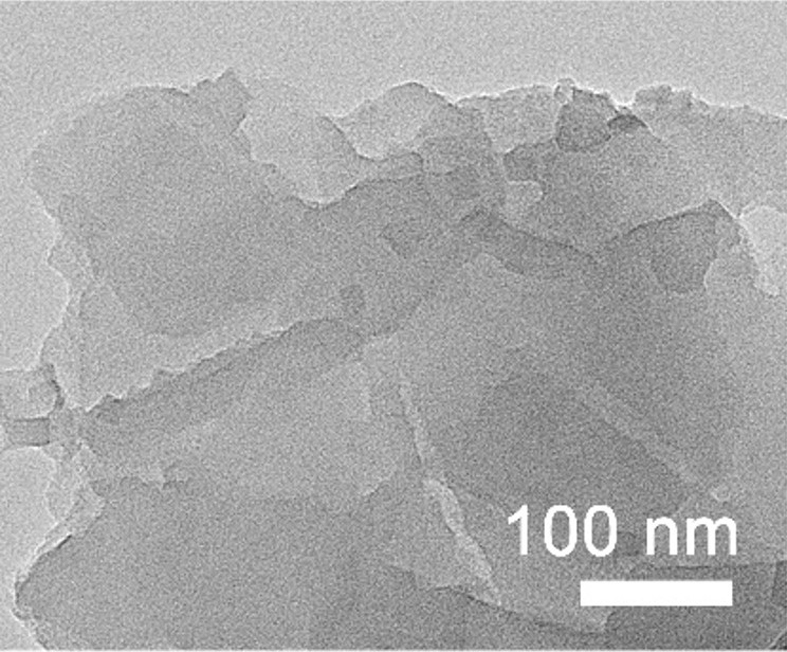

[0054] The difference from implementation 1 is that the mixed solvent of the first step is a mixture of ethanol and dimethyl sulfoxide, the solvent of the third step is methanol, the reaction time of the third step is 30 minutes, and the grown two-dimensional Zn-TCPP array is highly Extending to about 1.5 μm, the thickness of the Zn-TCPP sheet is nearly 100 nm. No dendrites were produced in the zinc deposition test, and the deposition pattern was U-shaped.

[0055] The rest are the same as in Embodiment 1, and are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com