A kind of double-layer solid electrolyte film for lithium battery and preparation method thereof

A technology for solid electrolytes and lithium batteries, applied in solid electrolytes, lithium batteries, non-aqueous electrolytes, etc., can solve problems such as poor chemical properties and poor interface compatibility, achieve improved dispersion, high binding force, and inhibit the growth of lithium dendrites Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

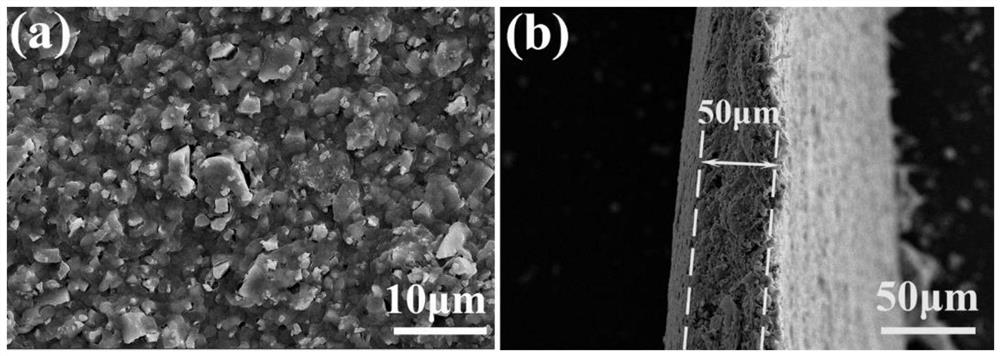

[0055] Embodiment 1: The preparation method of the double-layer solid electrolyte film that is used for lithium battery of the present embodiment, carries out according to the following steps:

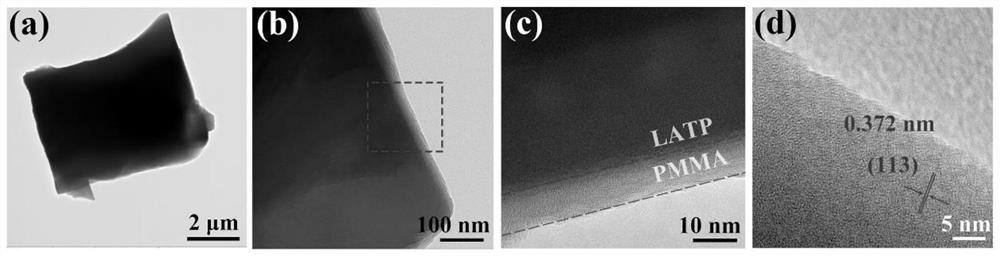

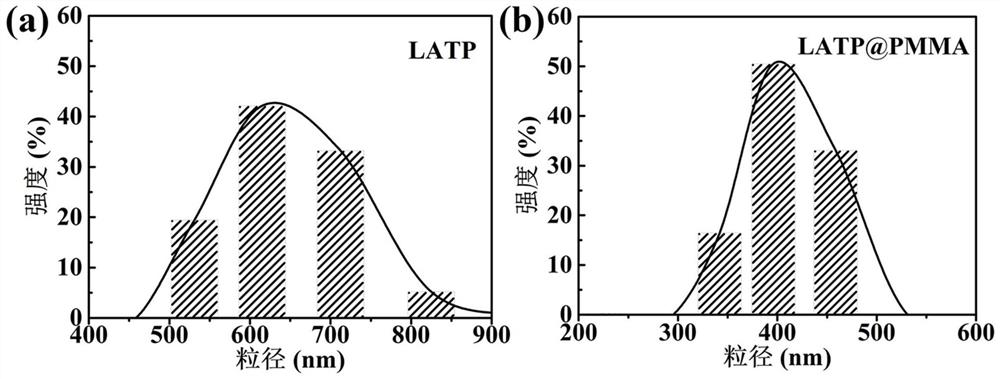

[0056] 1. Preparation of surface treatment agent-coated lithium ion conductor filler: 0.6g of aluminum doped lithium titanium phosphate (Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 , LATP) was dispersed in 5 mL of deionized water, and 1 g of polymethylmethacrylate (PMMA) dispersion solution was added, and stirred at room temperature for 12 hours to form a dispersion; the resulting dispersion was centrifuged, washed, and ultrasonically dispersed in sequence, and repeated Three times; the upper solvent after the third centrifugation was sucked out, the remaining solid phase at the bottom was taken out, and vacuum-dried at 80°C for 12 hours; polymethyl methacrylate-coated aluminum-doped lithium titanium phosphate (LATP@PMMA) was obtained; The dispersion solution of methyl methacrylate is a product...

Embodiment 2

[0080] Embodiment 2: The preparation method of the double-layer solid electrolyte film for lithium battery of the present embodiment is carried out according to the following steps:

[0081] 1. Preparation of surface treatment agent-coated lithium ion conductor filler: Disperse 0.6g of aluminum-doped lithium titanium phosphate in 5mL of deionized water, add 1g of polymethyl methacrylate dispersion solution, and stir at room temperature for 12 hours to form a dispersion; The resulting dispersion was centrifuged, washed, and ultrasonically dispersed in sequence, and repeated three times; the solvent in the upper layer after the third centrifugation was sucked out, and the remaining solid phase at the bottom was taken out, and vacuum-dried at 80°C for 12 hours; polymethyl methacrylate-coated Aluminum-doped lithium titanium phosphate; the dispersion solution of polymethyl methacrylate is a product of Soken Chemical&Enginerring Co., Ltd., the product model is MX-1000F, the solvent i...

Embodiment 3

[0088] Embodiment 3: The preparation method of the double-layer solid electrolyte film for lithium battery of the present embodiment is carried out according to the following steps:

[0089] 1. Preparation of surface treatment agent-coated lithium ion conductor filler: disperse 0.6g of aluminum-doped lithium titanium phosphate in 5mL of deionized water, add 1g of polymethyl methacrylate dispersion solution, and stir at room temperature for 12 hours to form a homogeneous solution ; Centrifuge, wash, and ultrasonically disperse the obtained solution in sequence, and repeat three times; suck out the upper solvent after the third centrifugation, take out the remaining solid phase at the bottom, and dry it in vacuum at 80°C for 12 hours to obtain a polymethyl methacrylate coating type Germanium-doped lithium titanium phosphate;

[0090] 2. Preparation of composite solid electrolyte solution: Disperse 0.6g of polymethyl methacrylate-coated aluminum-doped lithium titanium phosphate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com