Photoresist stripping liquid and preparation method thereof

A technology of photoresist and stripping solution, which is applied in the processing of photosensitive materials, etc., can solve the problems of increasing the difficulty and cost of product anti-corrosion process, easy-to-corrode substrate materials, etc., and achieve good deglue effect and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

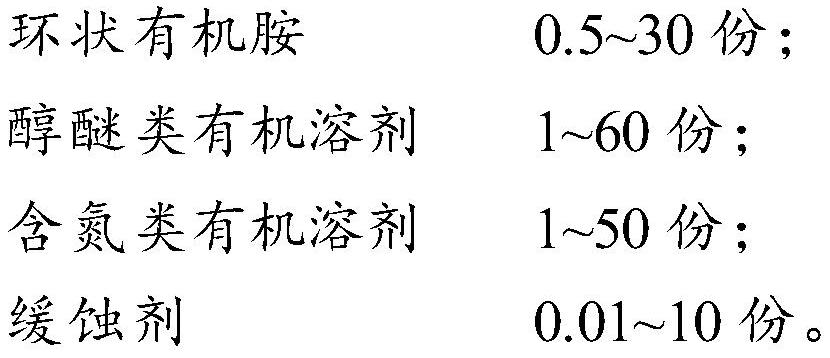

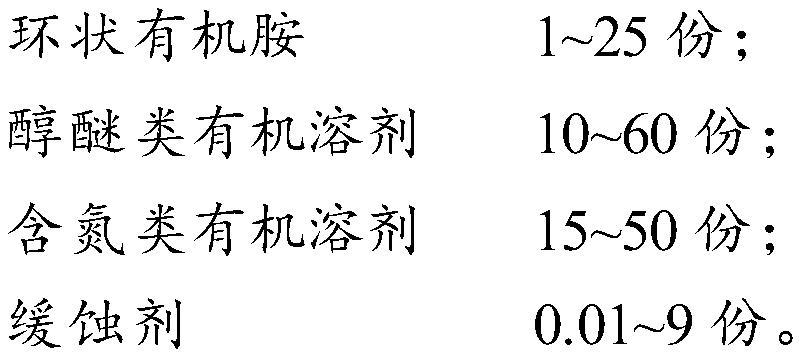

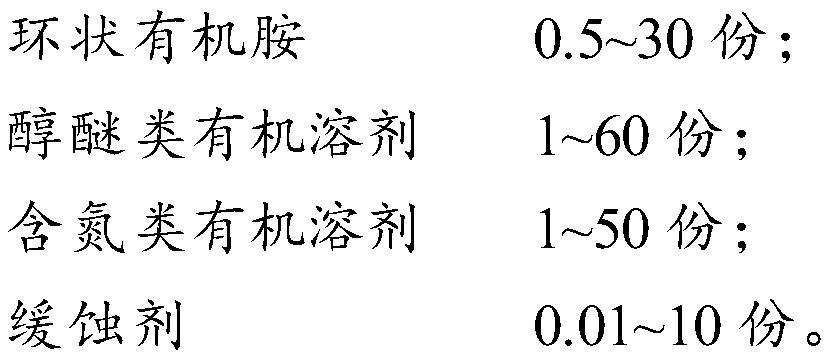

Method used

Image

Examples

preparation example Construction

[0045] The present invention provides a method for preparing a photoresist stripping solution according to any one of the above technical solutions, comprising the following steps:

[0046] The cyclic organic amine, alcohol ether organic solvent, nitrogen-containing organic solvent and corrosion inhibitor are mixed and dissolved with stirring, and then filtered.

[0047] The photoresist stripping solution of the present invention can be dissolved by adding the above-mentioned components in sequence, and the exothermic phenomenon of the organic base should be controlled during the dissolving process. The filter element is 1 μm or less.

[0048] The present invention provides a method for using the photoresist stripping solution described in any one of the above technical solutions, including:

[0049] The photoresist stripping solution described in any one of the above is used to clean the substrate containing the photoresist film by means of soaking or spraying, and then clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com