Magnesium oxide ceramic composite carbon fiber and preparation method thereof

A composite carbon fiber and ceramic composite technology, which is applied in fiber processing, textiles and papermaking, etc., to achieve the effects of overcoming mechanical strength and toughness, stabilizing the preparation process, and improving thermal oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

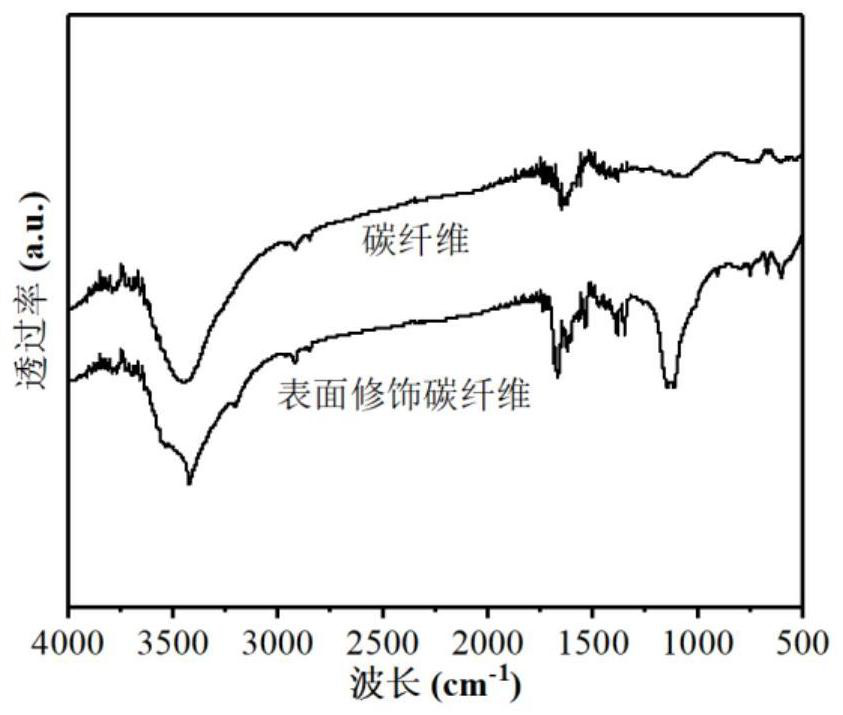

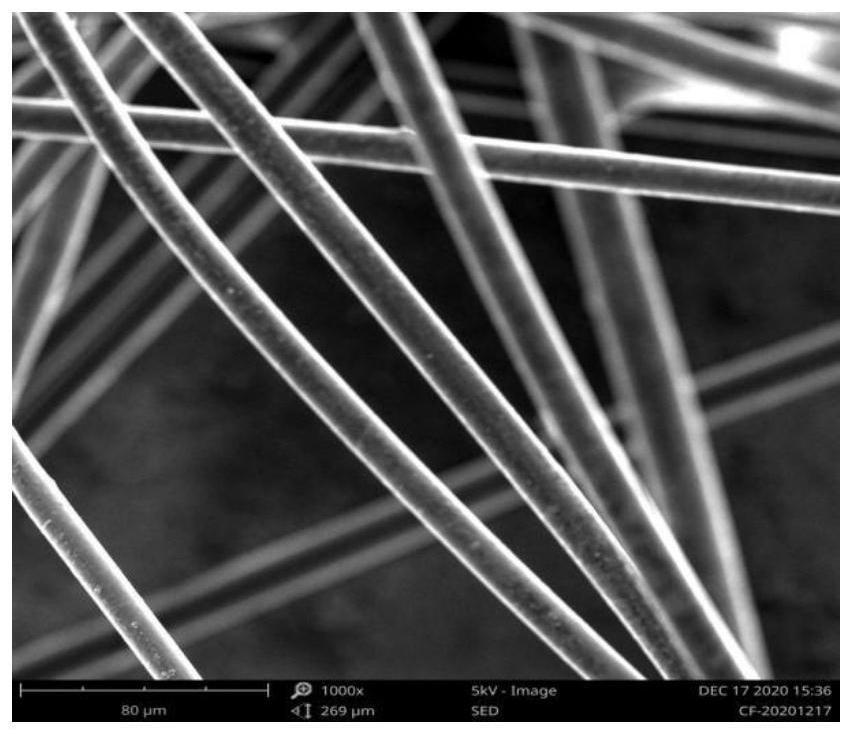

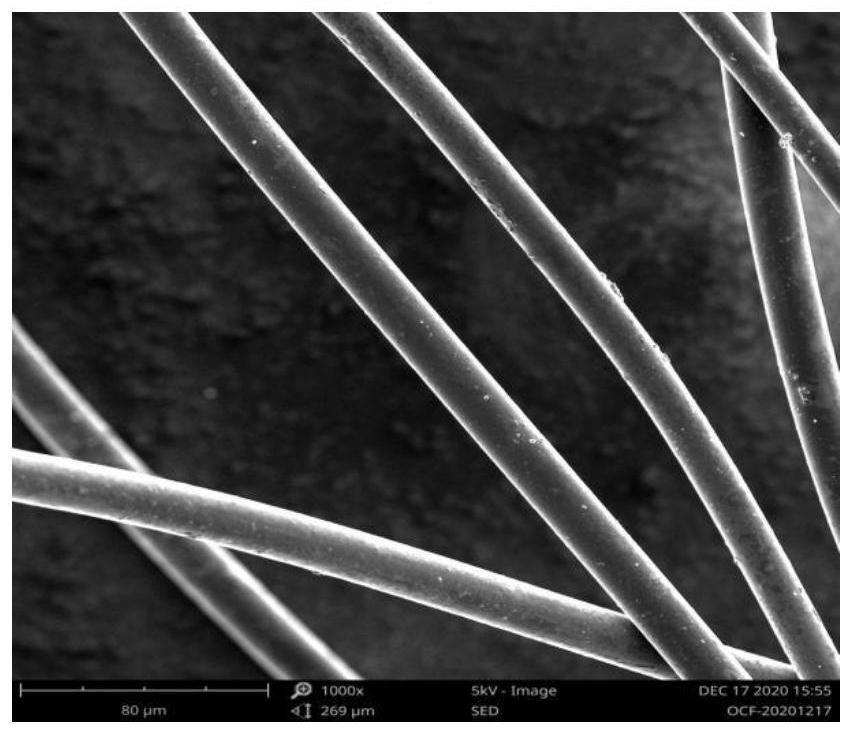

[0034] (1) Surface modification of carbon fiber

[0035] First, measure 300ml of a mixed solution of ethanol and acetone with a volume ratio of 1:1 as a cleaning agent, and then ultrasonically clean 1 g of carbon fiber without any treatment for 40 minutes. ; Then acidify the desizing carbon fiber with 50% nitric acid solution at 60°C for 2h (acidified carbon fiber CF-COOH), wash with water until neutral, and dry at 80°C for use.

[0036] (2) Magnesium oxide sol-gel coated surface-modified carbon fibers

[0037] Weigh 148g of propionic acid, dissolve it in 700g of water, the dissolution temperature is 35°C, and the stirring speed is 200r / min for 30min. After the solution is completely mixed, add 80g of magnesium oxide powder and continue to stir until the solution is completely clear. The solution was concentrated under reduced pressure to a homogeneous colorless sol-gel slurry with a viscosity of 135 Pa·s at 55°C. Then, 1 g of the surface-modified carbon fiber was dipped in ...

Embodiment 2

[0045] (1) Surface modification of carbon fiber

[0046] First, measure 300 ml of a mixed solution of ethanol and acetone with a volume ratio of 1:2 as a cleaning agent, and then ultrasonically clean 1 g of carbon fiber without any treatment for 40 minutes. ; Then acidify the desizing carbon fiber with 50% nitric acid solution at 60°C for 2h (acidified carbon fiber CF-COOH), wash with water until neutral, and dry at 80°C for use.

[0047] (2) Magnesium oxide sol-gel coated surface-modified carbon fibers

[0048] Weigh 148g of propionic acid, dissolve it in 700g of water, the dissolution temperature is 35°C, and the stirring speed is 200r / min for 30min. After the solution is completely mixed, add 80g of magnesium oxide powder and continue to stir until the solution is completely clear. The solution was concentrated under reduced pressure to a homogeneous colorless sol-gel slurry with a viscosity of 145 Pa·s at 55°C. Then 1 g of the surface-modified carbon fiber was dipped in ...

Embodiment 3

[0055] (1) Surface modification of carbon fiber

[0056] First, measure 200ml of a mixed solution of ethanol and acetone with a volume ratio of 1:1 as a cleaning agent, then ultrasonically clean 0.5g of carbon fiber without any treatment for 40 minutes. 10h; then acidified the desizing carbon fiber with 50% nitric acid solution at 60°C for 2h (acidified carbon fiber CF-COOH), washed with water until neutral, and dried at 60°C for use.

[0057] (2) Magnesium oxide sol-gel coated surface-modified carbon fibers

[0058] Weigh 60g of acetic acid, dissolve it in 200g of water, the dissolution temperature is 35°C, and the stirring speed is 200r / min for 30min. After the solution is completely mixed, add 40g of magnesium oxide powder and continue to stir until the solution is completely clear. At 65 °C, it was concentrated to a homogeneous colorless sol-gel slurry with a viscosity of 155 Pa·s by distillation under reduced pressure. Then 0.5 g of surface-modified carbon fibers were d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com