Winding and packaging equipment for stainless steel pipe body

A stainless steel pipe and equipment technology, which is applied in the field of stainless steel pipe winding and packaging equipment, can solve the problems of affecting the packaging quality, burrs, and puncture of the packaging film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

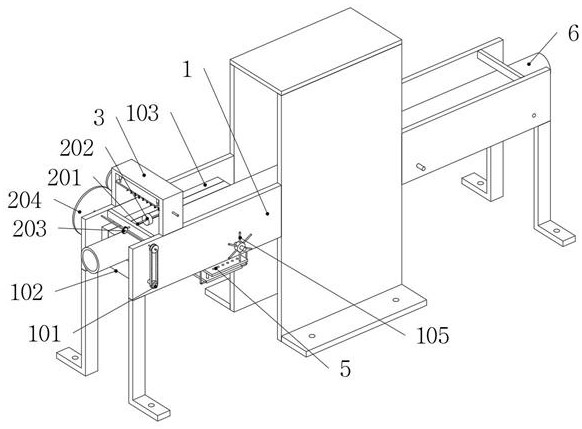

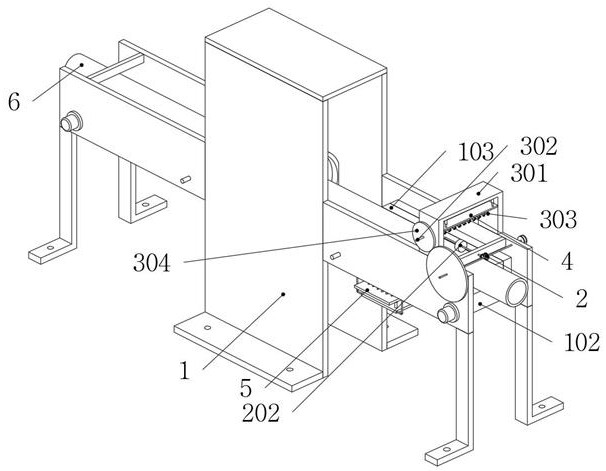

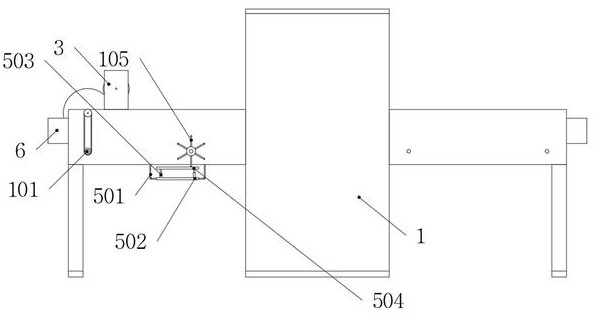

[0038] Example: please refer to Figure 1 to Figure 9 :

[0039] The present invention proposes a wrapping and packaging equipment for stainless steel pipe body, comprising: a frame body 1, a driving part 2, a heat dissipation part 3, a purification part 4 and a cleaning part 5;

[0040] The frame body 1 is fixed on the ground;

[0041] The driving part 2 is composed of a rotating shaft A201, a friction wheel 202, a bevel gear 203, a rotating shaft B204 and a gear A205, and the rotating shaft A201 is rotatably connected to the frame body 1;

[0042] The heat dissipation part 3 is composed of a seat body 301, a rotating shaft C302, an impeller 303 and a gear B304, and the seat body 301 is welded on the top surface of the frame body 1;

[0043] The purification part 4 is composed of an elastic telescopic rod A401, a force plate 402, a piston bottle 403, a water storage box 404, an exhaust pipe 405, a connecting pipe 406, a suction pipe 407 and a through hole A408, and the elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com