On-line rotor and stator axial clearance measuring device based on dual-wavelength sweep frequency intensity modulation

A technology of intensity modulation and axial gap, applied in measuring devices, optical devices, instruments, etc., can solve the problems of high temperature resistance, large transmission loss, and large temperature drift of magnetic cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

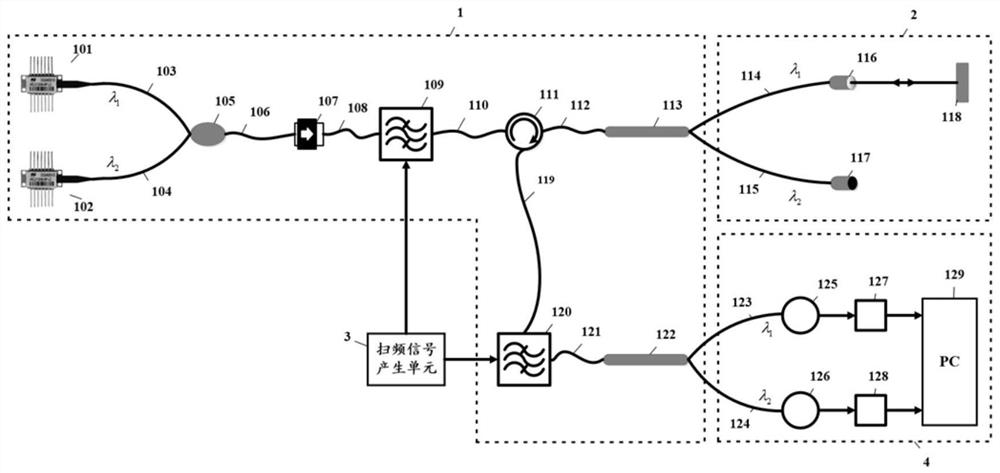

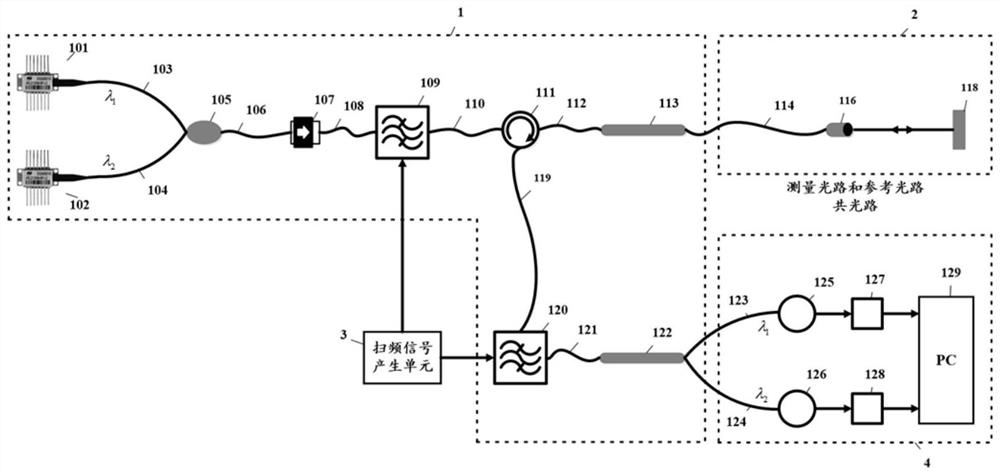

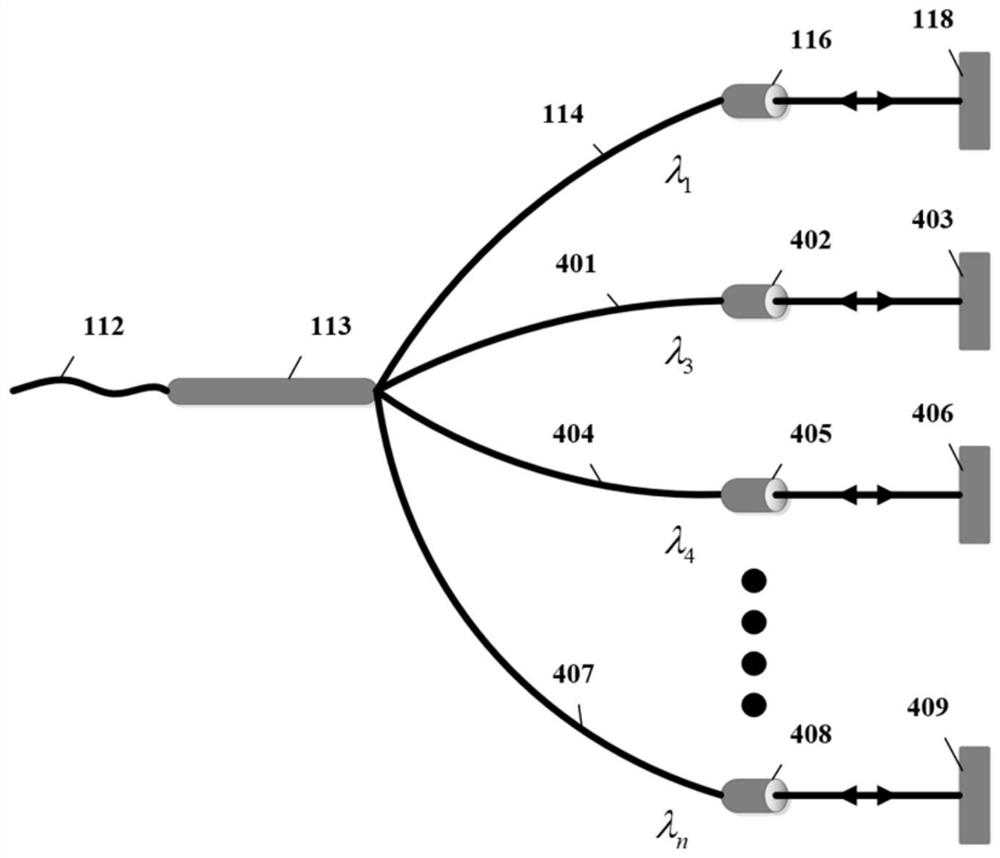

[0042] This embodiment discloses an on-line measurement device for rotor-stator axial gap based on dual-wavelength sweep frequency intensity modulation, which is characterized by comprising a secondary modulation optical path unit 1, a measurement optical path and a reference optical path unit 2, a frequency sweep signal generation unit 3, Data acquisition and processing unit 4; secondary modulation optical circuit unit 1 consists of a first laser 101, a second laser 102, a coupler 105, an isolator 107, a first electro-optical intensity modulator 109, a circulator 111, a first wavelength division multiplexer The data acquisition and processing unit 4 consists of a first detector 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com