Heating device used for surface machining of daylighting panel and facilitating feeding

A surface processing and heating device technology, applied in lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of inconvenient introduction of lighting panels, insufficient heating effect of lighting panels, etc., to achieve simple and convenient cutting, improve heating effect, Comprehensive and effective heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the above technical solutions, the above technical solutions will be described in detail below with reference to the accompanying drawings and specific embodiments.

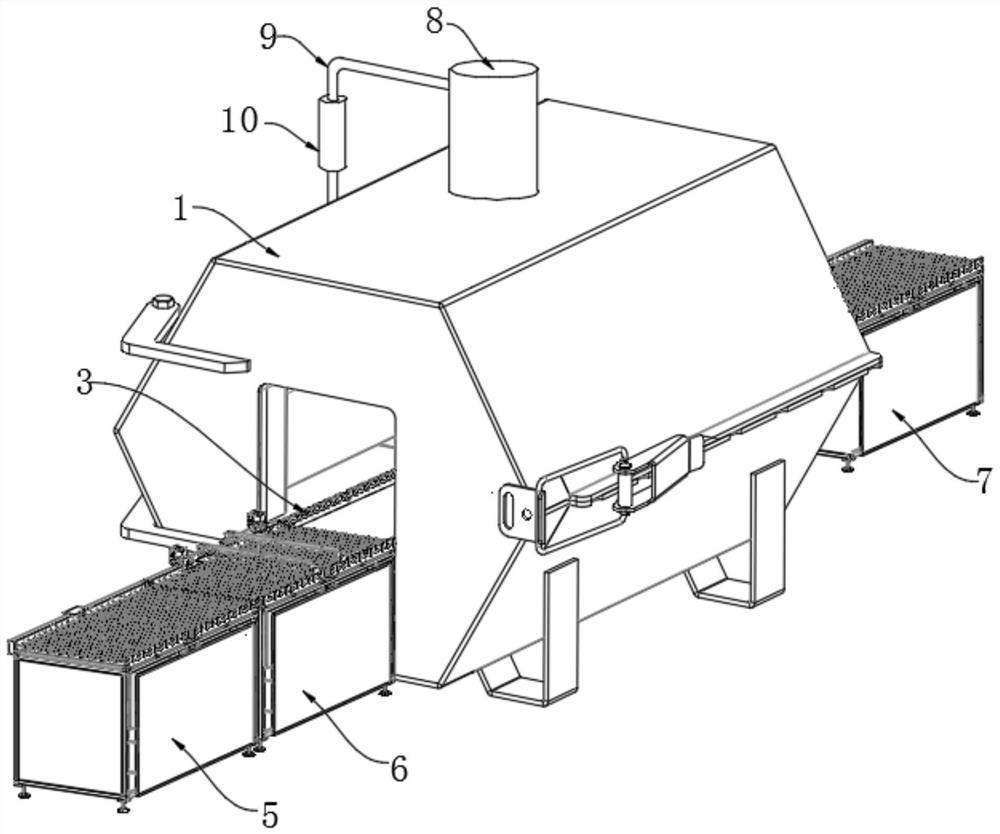

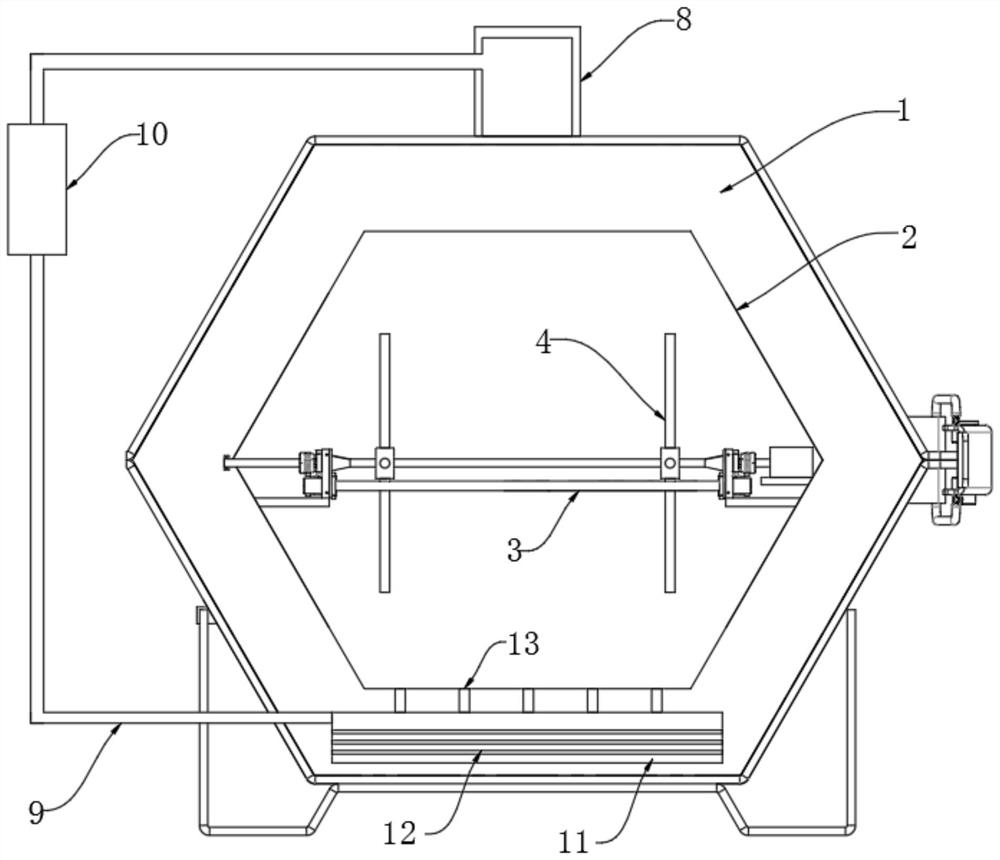

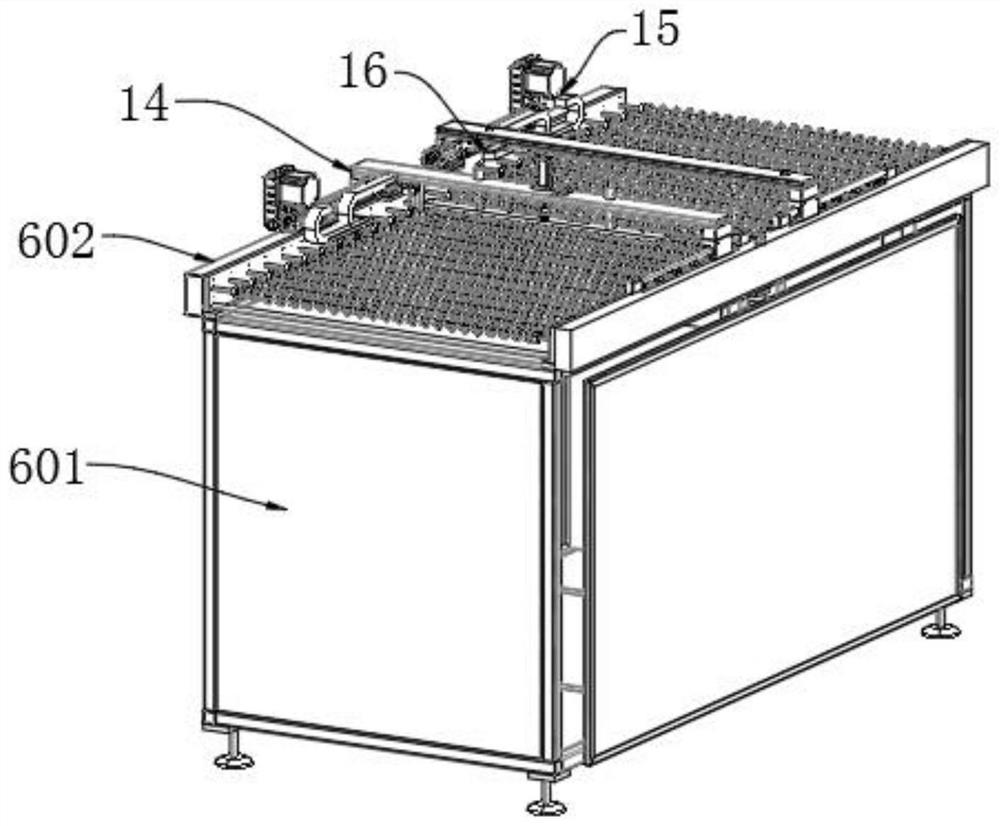

[0038] see Figures 1 to 9 , in the embodiment of the present invention, a heating device for the surface processing of the lighting board that is convenient for feeding, including a heating furnace 1, a heating cavity 2 is opened inside the heating furnace 1, and the interior of the heating cavity 2 is fixedly connected with two Conveying assemblies 3 in parallel, a turning assembly 4 is arranged between the two conveying assemblies 3, one side of one conveying assembly 3 is fixedly connected with the second guide table 6 and the first guide table 5, and one side of the other conveying assembly 3 is fixedly connected. The side is fixedly connected with a third material guide table 7, the first material guide table 5, the second material guide table 6 and the third material gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com