Ultrafine grain biodegradable zinc alloy as well as preparation method and application thereof

A technology of ultra-fine grain and zinc alloy, applied in the field of alloy materials, can solve the problems of less slip system, low mechanical strength and toughness, easy formation of fiber texture or plate texture, etc., and achieve improved mechanical strength and toughness, high mechanical strength The effect of toughness and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of an ultrafine-grained biodegradable zinc alloy, comprising the following steps:

[0031] Heating zinc to melting to obtain zinc liquid;

[0032] Adding aluminum or magnesium to the zinc liquid, smelting to obtain an alloy liquid;

[0033] The alloy liquid is poured to obtain an as-cast billet;

[0034] The as-cast billet is subjected to homogenization heat treatment to obtain a plate;

[0035] The sheet is hot rolled to obtain an ultrafine grain biodegradable zinc alloy.

[0036] In the present invention, zinc is heated to melt to obtain zinc liquid. In the present invention, the melting temperature is preferably 650°C.

[0037] After the zinc liquid is obtained, in the present invention, aluminum or magnesium is added to the zinc liquid and smelted to obtain an alloy liquid. In the present invention, when aluminum is added to the zinc solution, the content of aluminum in the alloy solution is preferably 0.5-1.5wt%, mor...

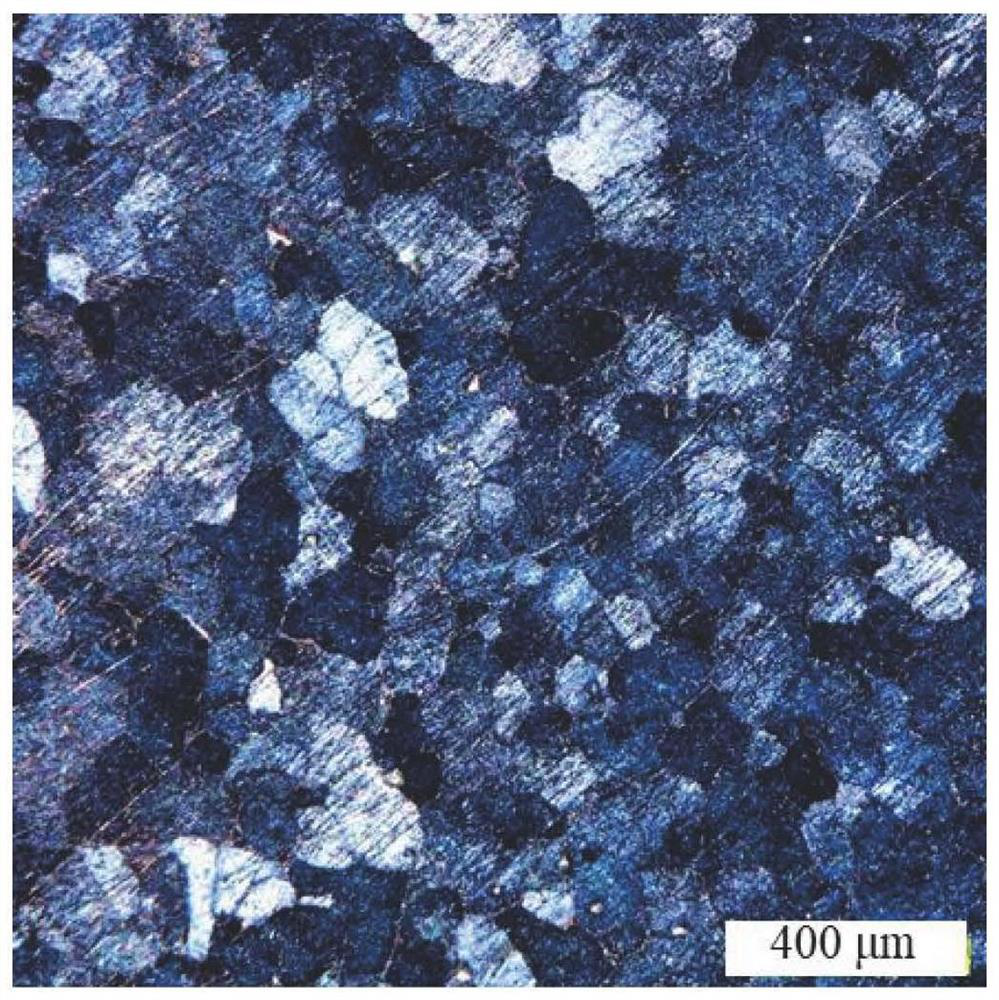

Embodiment 1

[0052] Using metal zinc and metal aluminum as raw materials, according to the ratio of 99.0wt% Zn and 1.0wt% Al, first put metal zinc into a resistance furnace at 650 ℃, after it is melted, add 1.0wt% Al, After all the metal is melted, stir until the mixture is uniform, keep it at rest for 15 minutes, vibrate with an ultrasonic vibrator for 5 minutes, and pour it into a graphite crucible preheated to 200 ° C in advance to obtain a cylindrical cast with a diameter of 40 mm and a length of 180 mm. blank;

[0053] The as-cast billet is subjected to homogenization heat treatment, and the heat treatment process is as follows: heating up to 300° C. with the furnace and keeping the temperature for 3 hours, air-cooling to room temperature, and then cutting the heat-treated billet into a 60mm×20mm×3mm plate;

[0054] Put the plate into a resistance furnace and heat it to 200°C with the furnace, then put it into a four-roll mill for hot rolling, set a single pass reduction of 0.5mm, and...

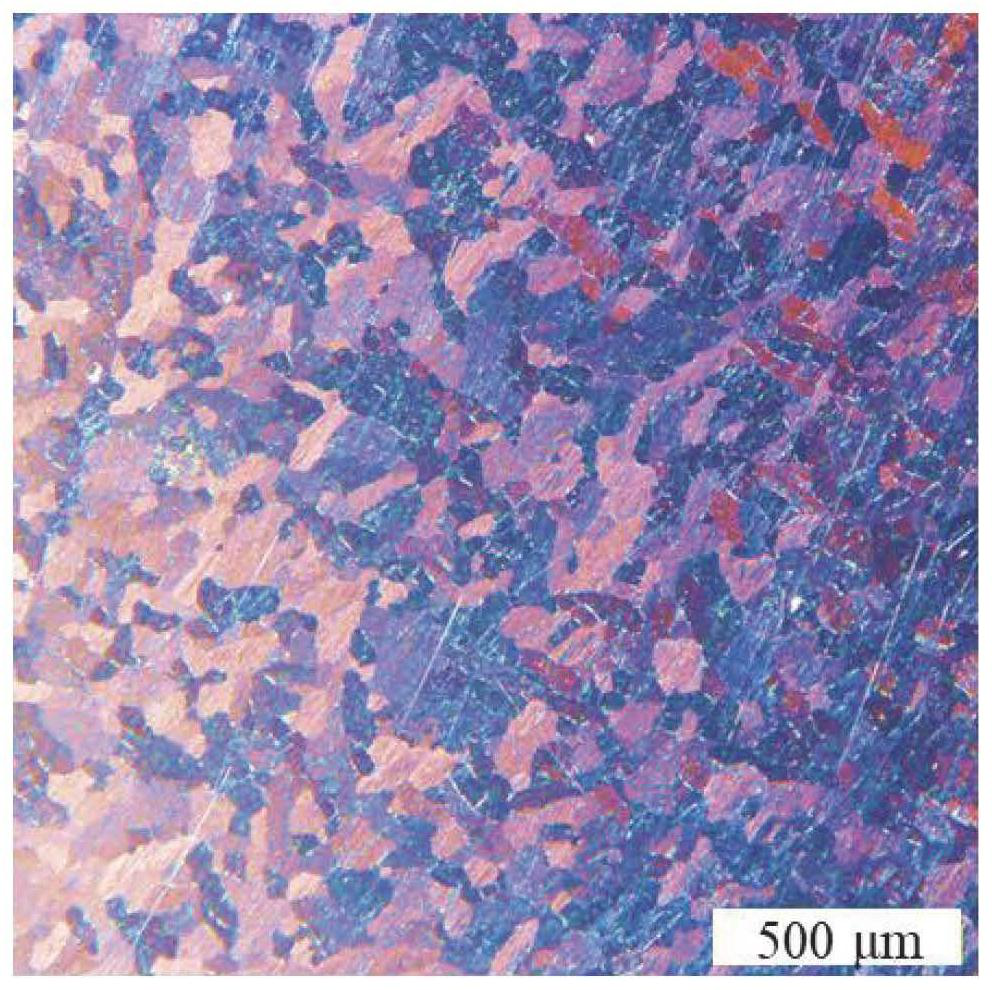

Embodiment 2

[0058] Using metal zinc and Zn-50wt% Mg as raw materials, according to the ratio of 99.9wt% Zn and 0.1wt% Mg, first put metal zinc into a resistance furnace at 650 ℃, after it is melted, add 0.1wt% After all the metal is melted, stir until the mixture is uniform, keep it at rest for 15 minutes, vibrate with an ultrasonic vibrator for 5 minutes and pour it into a graphite crucible preheated to 200 ° C in advance to obtain a cylinder with a diameter of 40 mm and a length of 180 mm. as-cast billet;

[0059] The as-cast billet is subjected to homogenization heat treatment, and the heat treatment process is as follows: heating up to 300° C. with the furnace and keeping the temperature for 3 hours, air-cooling to room temperature, and then cutting the heat-treated billet into a 60mm×20mm×3mm plate;

[0060] Put the plate into a resistance furnace and heat it to 200°C with the furnace, then put it into a four-roll mill for hot rolling, set a single pass reduction of 0.5mm, and put it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com