7-series aluminum alloy hot top casting process for new energy automobile

A new energy vehicle, hot top casting technology, applied in the field of aluminum alloy casting, can solve the problems of extruded profile strain, center cracks, edge cracks, etc., to reduce the tendency of melting back, improve crack resistance, reduce range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

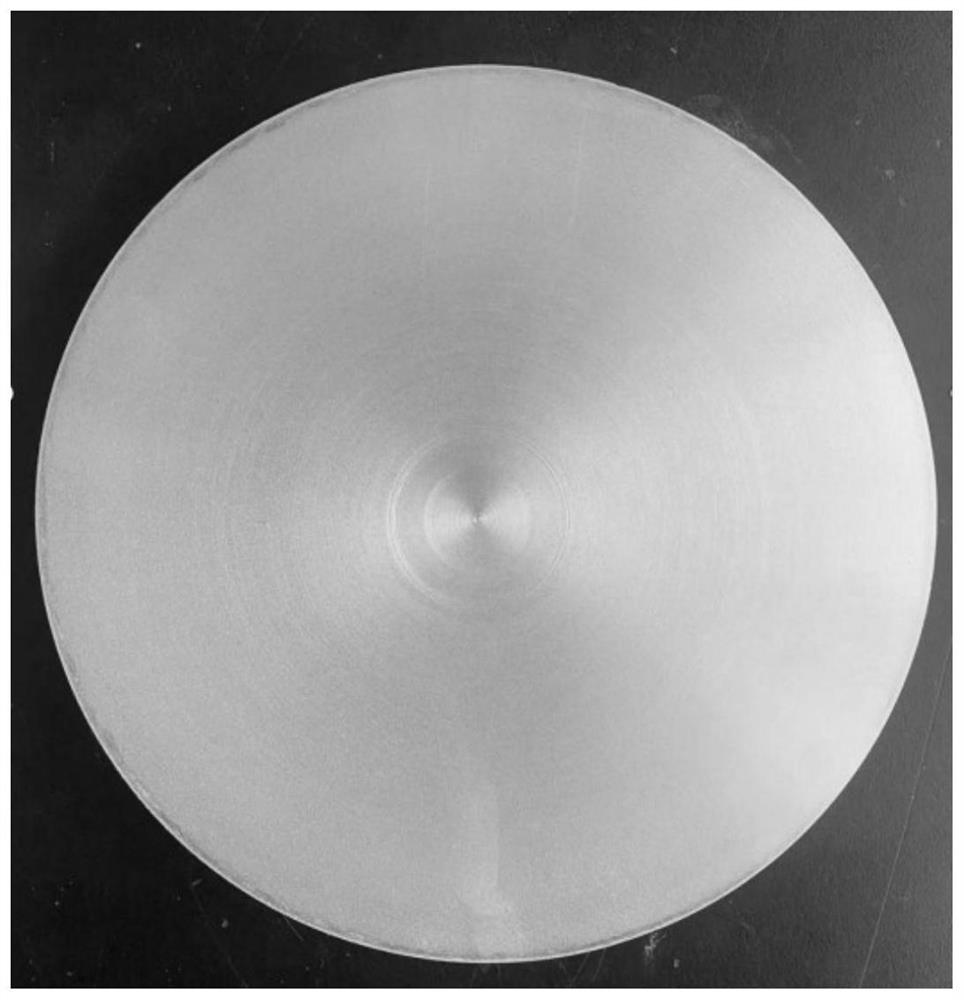

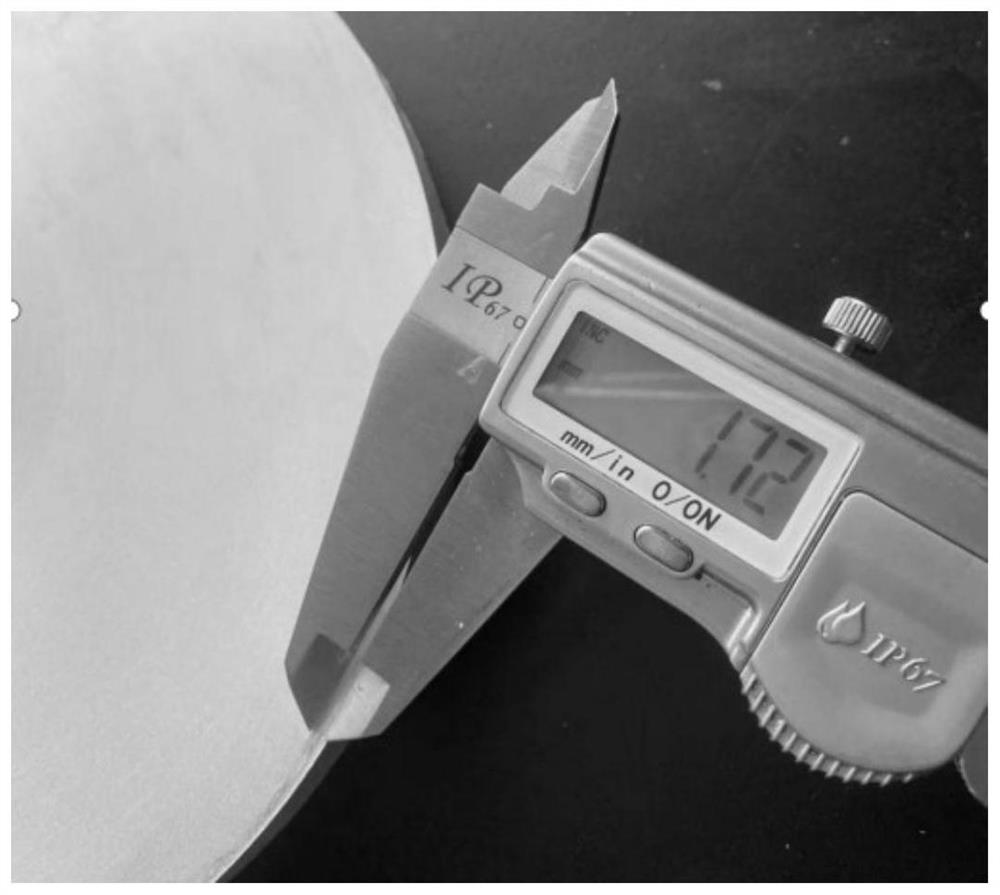

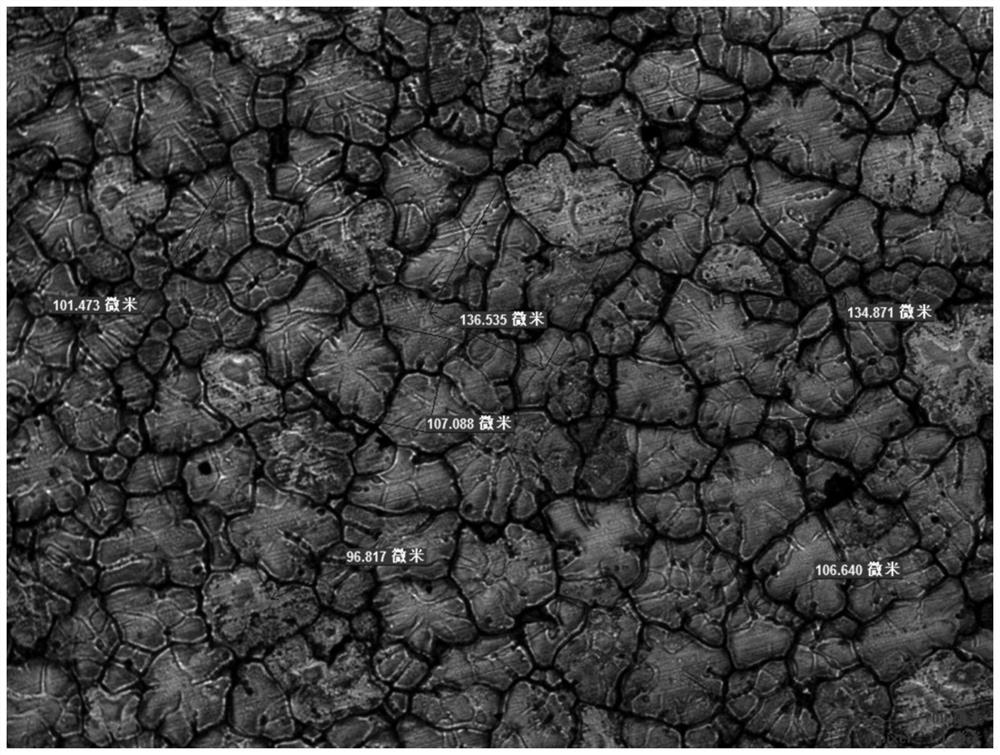

Image

Examples

Embodiment 1

[0034] The 7-series aluminum alloy of the present invention includes the following components by weight:

[0035] Si≤0.10 part, Fe≤0.20 part, Cu0.45 part, Mn0.10 part, Mg1.30 part, Cr0.10 part, Zn5.60 part, Ti0.03 part, balance Al.

[0036] The 7-series aluminum alloy hot-top casting process includes the following process steps:

[0037] (1) Feeding: 20 parts of cold material (aluminum rod head and tail of the same material and profile return material) and 80 parts of electrolytic aluminum liquid are added to the regenerative smelting furnace;

[0038] (2) Smelting: After the molten aluminum reaches the temperature (740-750°C), the alloying elements are added after slag removal, and electromagnetic stirring is used to ensure uniform composition;

[0039] (3) Refining: After the first refining in the smelting furnace, the adjusted components are transferred to the holding furnace for secondary refining. During refining, high-purity argon gas is used to blow into the melt toget...

Embodiment 2

[0053]The 7-series aluminum alloy of the present invention includes the following components by weight:

[0054] Si≤0.10 part, Fe≤0.20 part, Cu0.45-0.55 part, Mn0.15 part, Mg1.40 part, Cr0.15 part, Zn6.00 part, Ti0.06 part, balance Al.

[0055] The 7-series aluminum alloy hot-top casting process includes the following process steps:

[0056] (1) Feeding: 30 parts of cold material (aluminum rod head and tail of the same material and profile return material) and 70 parts of electrolytic aluminum liquid are added to the regenerative smelting furnace;

[0057] (2) Smelting: After the molten aluminum reaches the temperature (740-750°C), the alloying elements are added after slag removal, and electromagnetic stirring is used to ensure uniform composition;

[0058] (3) Refining: After the first refining in the smelting furnace, the adjusted components are transferred to the holding furnace for secondary refining. During refining, high-purity argon gas is used to blow into the melt t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com