Preparation method of flaky magnetic electrothermal composite material

A composite material and magnetic technology, used in heating/cooling reflective point instruments, sustainable construction, acupuncture, etc., can solve the problems of silicon carbide component burning, restricting wide application, restricting development and application, etc., to achieve low production costs , Excellent thermal conductivity, convenient process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

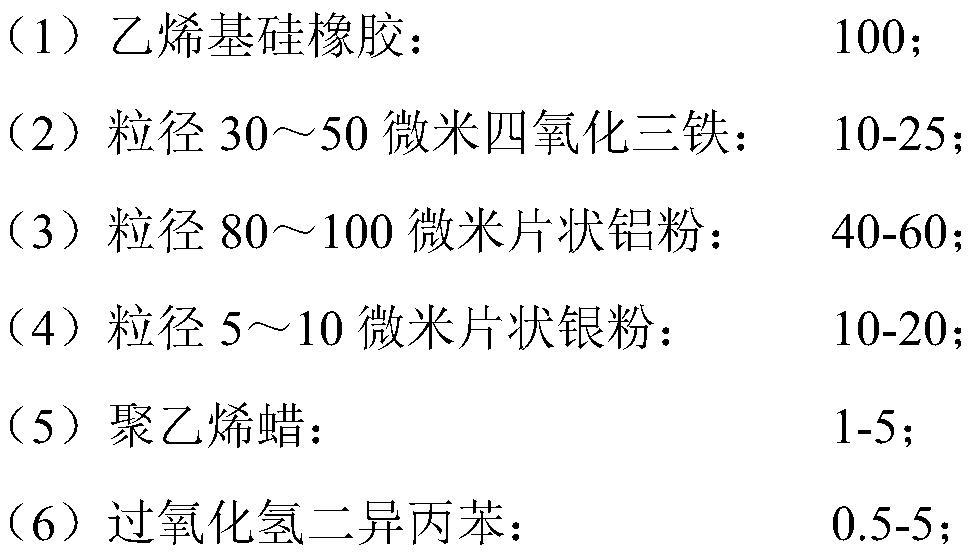

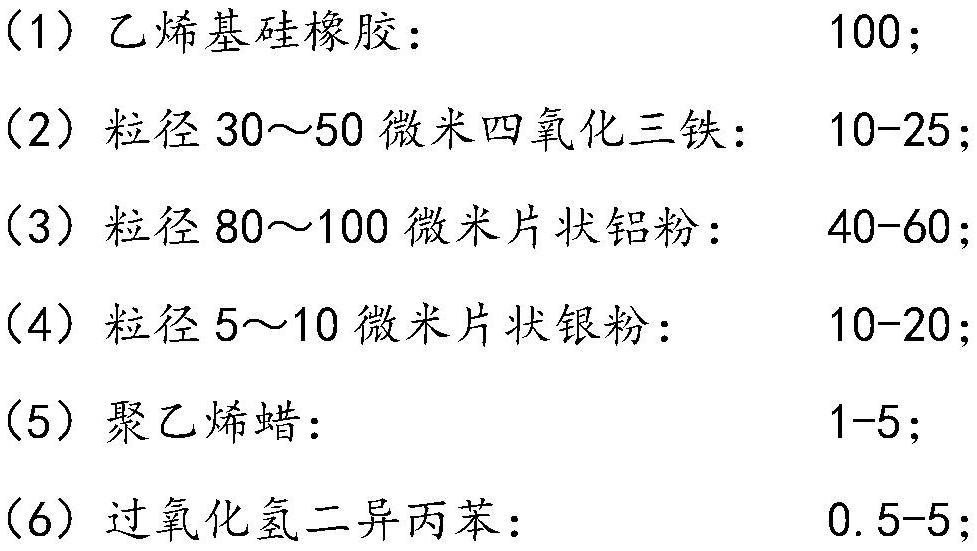

[0039] (1) Select vinyl silicone rubber (Chenguang Chemical Research Institute), vinyl content 5%, melt index 5.8g / 10min (2.16kg, 190 ℃), iron tetroxide (particle size 30 ~ 50 microns, Chengdu Maike Rui New Materials Co., Ltd.), flake aluminum powder (particle size 80-100 microns, China Aluminum Industry Shandong Branch), flake silver powder (particle size 5-10 microns, Guiyan Platinum), polyethylene wax (melting point 65℃) , Yanshan Petrochemical Company), dicumyl hydrogen peroxide (analytical grade, Chengdu Kelong Reagent Co., Ltd.). First, dry ferric oxide, aluminum powder and silver powder in an oven at 80°C for 12 hours;

[0040] (2) each raw material is weighed and prepared, and the proportion by weight of the prepared material is: the weight ratio of vinyl silicone rubber, iron tetroxide, aluminum powder, silver powder, polyethylene wax, dicumyl hydrogen peroxide is 100:20: 60:15:3:0.5, put polyethylene wax, dried ferric oxide and aluminum powder into the ceramic high-...

Embodiment 2

[0068] (1) Select vinyl silicone rubber (Chenguang Chemical Research Institute), vinyl content 5%, melt index 5.8g / 10min (2.16kg, 190 ℃), iron tetroxide (particle size 30 ~ 50 microns, Chengdu Maike Rui New Materials Co., Ltd.), flake aluminum powder (particle size 80-100 microns, China Aluminum Industry Shandong Branch), flake silver powder (particle size 5-10 microns, Guiyan Platinum), polyethylene wax (melting point 65℃) , Yanshan Petrochemical Company), dicumyl hydrogen peroxide (analytical grade, Chengdu Kelong Reagent Co., Ltd.). First, dry ferric oxide, aluminum powder and silver powder in an oven at 80°C for 12 hours;

[0069] (2) each raw material is weighed and prepared, and the proportion by weight of the prepared material is: the weight ratio of vinyl silicone rubber, ferric oxide, aluminum powder, silver powder, polyethylene wax, and dicumyl hydrogen peroxide is 100:25: 50:15:3:1, put polyethylene wax, dried ferric oxide and aluminum powder into the ceramic high-...

Embodiment 3

[0090] (1) Select vinyl silicone rubber (Chenguang Chemical Research Institute), vinyl content 5%, melt index 5.8g / 10min (2.16kg, 190 ℃), iron tetroxide (particle size 30 ~ 50 microns, Chengdu Maike Rui New Materials Co., Ltd.), flake aluminum powder (particle size 80-100 microns, China Aluminum Industry Shandong Branch), flake silver powder (particle size 5-10 microns, Guiyan Platinum), polyethylene wax (melting point 65℃) , Yanshan Petrochemical Company), dicumyl hydrogen peroxide (analytical grade, Chengdu Kelong Reagent Co., Ltd.). First, dry ferric oxide, aluminum powder and silver powder in an oven at 80°C for 12 hours;

[0091] (2) each raw material is weighed and prepared, and the proportion by weight of the prepared material is: the weight ratio of vinyl silicone rubber, ferric oxide, aluminum powder, silver powder, polyethylene wax, and dicumyl hydrogen peroxide is 100:25: 50:20:1:3, put polyethylene wax, dried ferric oxide and aluminum powder into a ceramic high-mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com