Method for monitoring tool wear state through enhanced comparative learning of Gramer angle field

A Graham angle field and tool wear technology, which is applied in manufacturing tools, measuring/indicating equipment, metal processing equipment, etc., can solve problems such as difficult selection of basis function or kernel function parameters, limited label samples, and neural network overfitting , to achieve the effect of overcoming good performance and reducing experiment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

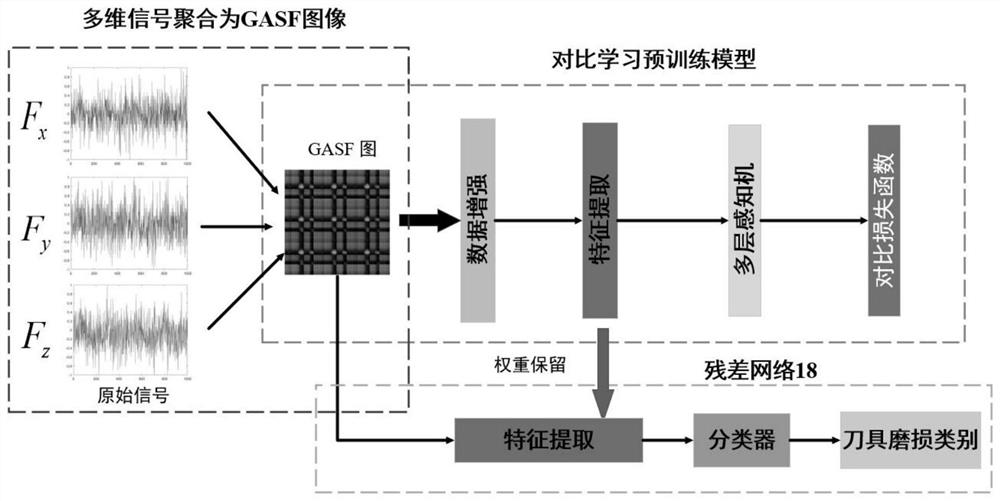

[0045] Example 1: A Gramm angle field enhanced contrast learning monitoring method for tool wear status, such as figure 1 shown, including the following steps:

[0046]Step 1. Collect cutting force signals in three directions and their corresponding tool wear states during the cutting process of the tool, and obtain labeled samples and non-labeled samples. The labeled samples are composed of the cutting force signals and The tool wear state is composed of; the unlabeled sample is composed of the cutting force signal in the intermediate stage of tool processing; the device collected in this embodiment is a TCM experimental device, and the tool wear state is that the tool is milled ten times on the workpiece surface, The length of each milling is 1.5m, each milling includes three forward milling and two reverse milling, and the sampling frequency is 12000Hz. After each milling is completed, the tool is removed and the tool microscope is used to take a wear picture; the tool flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com