A device for installing an optical probe under high temperature and vibration conditions

An optical probe and conditional technology, which is applied in the direction of measuring devices, material analysis through optical means, scientific instruments, etc., can solve problems such as the difficulty of installing optical probes, improve measurement accuracy and accuracy, ensure accuracy and precision, and reduce offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

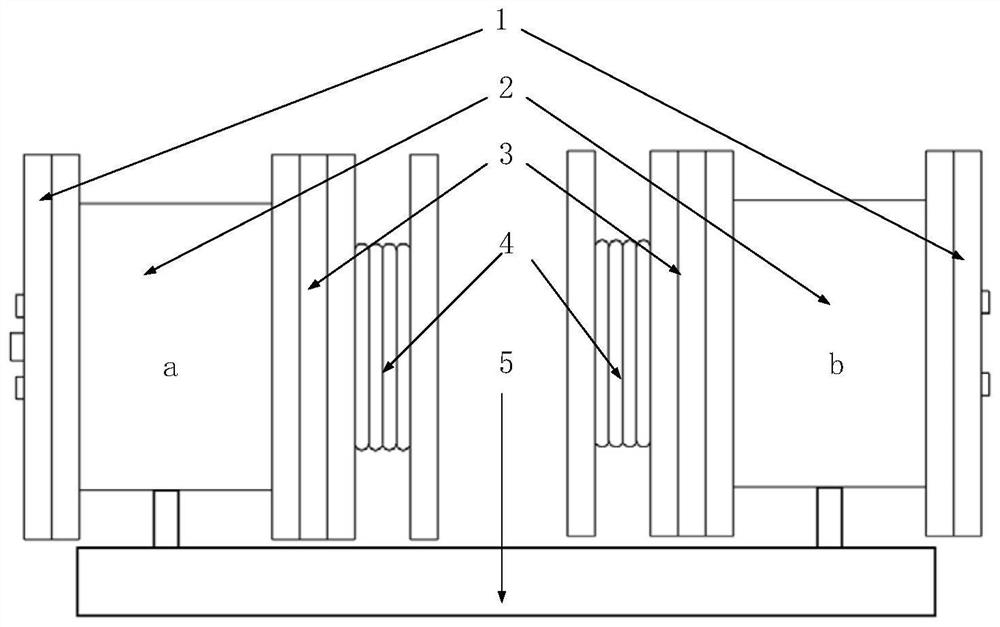

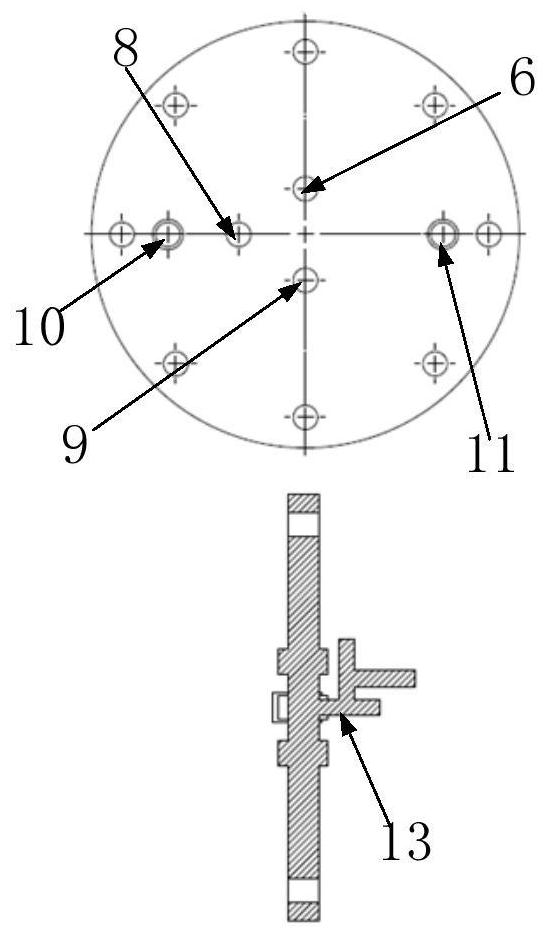

[0037] figure 1 It is a specific implementation of the high-precision optical probe installation device under high temperature and vibration conditions, including a laser emitting device a on the left and a laser receiving device b on the right, wherein the devices at both ends include a vacuum flange 1 and a vacuum cavity 2 , wedge-shaped window vacuum flange 3, corrugated chamber 4, and vacuum flange 1, vacuum chamber 2, wedge-shaped window vacuum flange 3, and corrugated chamber 4 are provided with 8 evenly distributed through holes at both ends. Among them, one end of the vacuum flange 1 is connected to one end of the vacuum chamber 2, and the other end of the vacuum chamber 2 is connected to one end of the wedge-shaped window vacuum flange 3, and a sapphire window 22 is opened on it to ensure that the light beam can effectively enter the interior of the combustion chamber; the wedge-shaped window The other end of the vacuum flange 3 and the corrugated cavity. At the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com