Automatic bottoming process method for process pipeline robot

A technology of process pipeline and process method, which is applied in the field of process pipeline robot automatic bottoming process, can solve the problems of complex process and low welding efficiency, and achieve the effects of simplified process, fast welding speed and beautiful weld shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

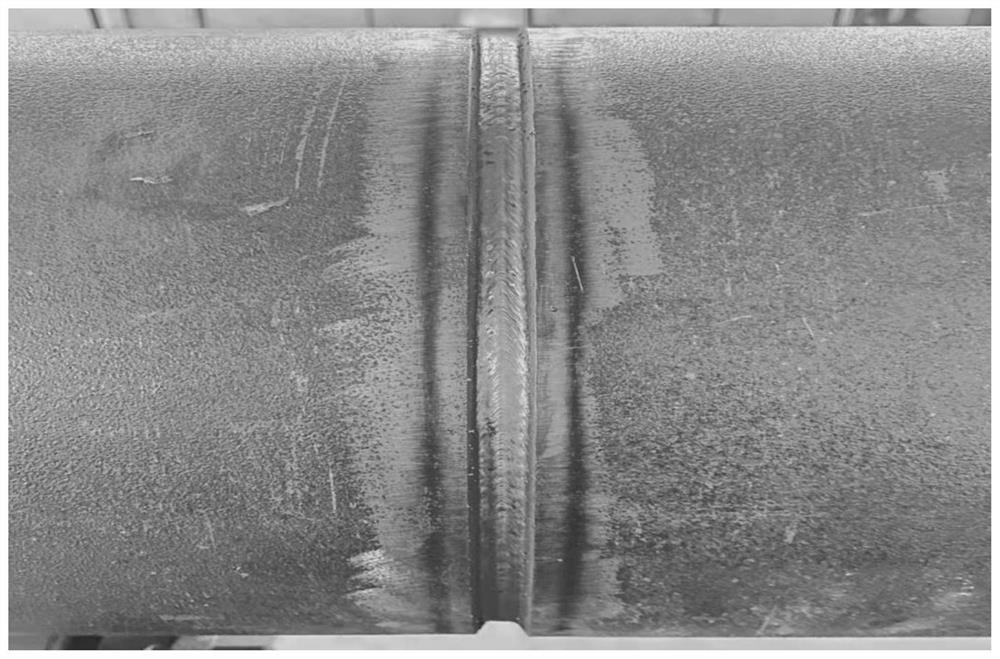

[0027] A process method for automatic bottoming of a process pipeline robot provided by the present embodiment is specifically as follows:

[0028] 1. Welding equipment and materials

[0029] (1) The welding equipment is a CLOOS welding robot, the model is QRC-410E, which is used in conjunction with the CLOOS welding power source model Qineo Pulse 451 PRO and positioner;

[0030] (2) The base metal of the welding material is Q235B (low alloy steel), the specification is Φ273×10mm, the yield strength>235Mpa, the tensile strength>415MPa; the low alloy steel gas shielded welding wire JQ·MG50- with a wire diameter of Φ1.2mm is used 6.

[0031] 2. Preparation before welding

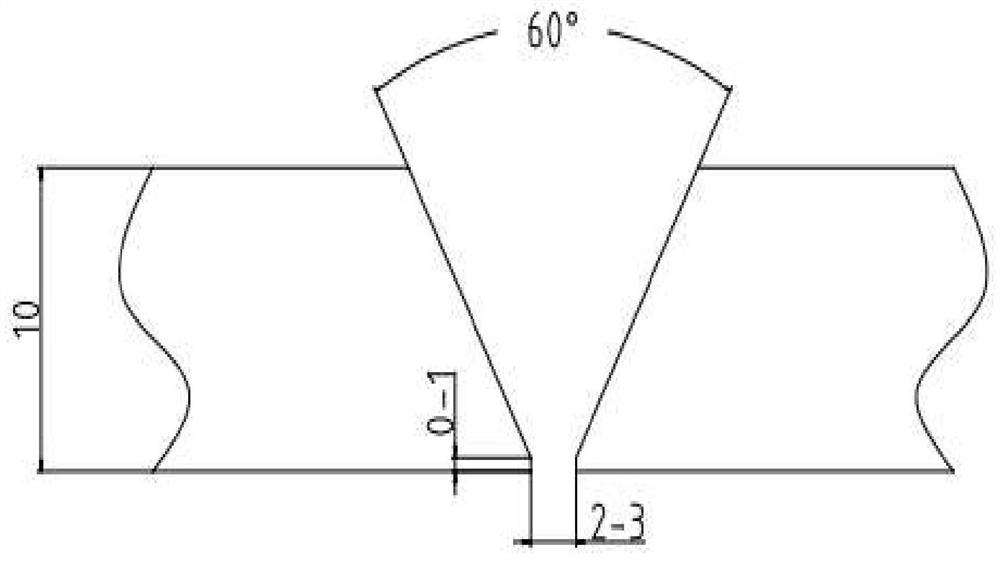

[0032] (1) Bevel processing: V-shaped bevels are made on Q235B low-alloy steel by lathe processing. The bevel angle is 30° on one side, the blunt edge is 0-1mm, and the gap is 2-3mm. The pipe roundness needs to be corrected during the groove processing. , to ensure that the amount of misalignment is less th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com