Preparation method of double-layer microneedle patch for atopic dermatitis

A technology for atopic dermatitis and microneedle patches, applied in the field of biomedical materials, can solve the problems of poor treatment effect, microneedle patches without atopic dermatitis, and insufficient mechanical properties of microneedle patches, which are not easy to achieve Immune rejection, relief of symptoms of atopic dermatitis, strong biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

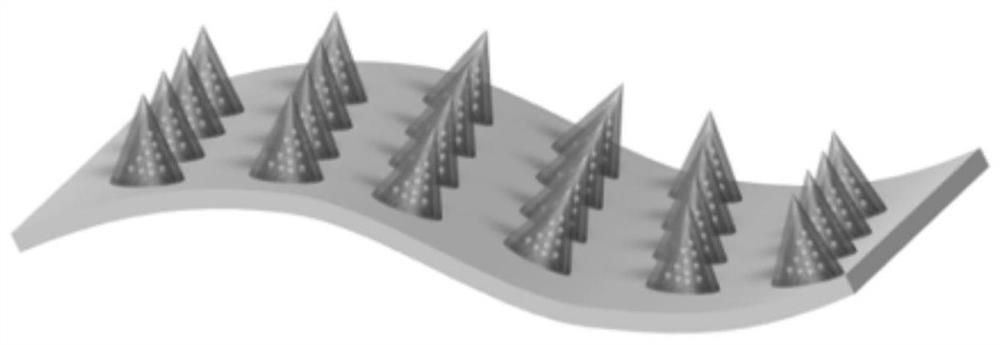

[0032] The invention provides a preparation method of a double-layer microneedle patch for atopic dermatitis, comprising the following steps:

[0033] 1) Preparation of inner layer microneedles: Fill the microneedle tip inner layer raw material solution containing the therapeutic drug into a small template with needle-like holes, after the microneedle tip inner layer raw material solution is solidified, fill the microneedle backing layer raw material solution into the template, and demould after drying to obtain the inner layer microneedle patch;

[0034] 2) Preparation of double-layer microneedles: Fill the microneedle tip outer layer raw material solution into a large template with needle-shaped holes, scrape off the excess solution, press the inner layer microneedle patch into the large template, and dry it. After demoulding, a double-layer microneedle patch was prepared.

[0035] The microneedle tip inner layer raw material solution is selected from one or more of methacr...

Embodiment 1

[0049] A double-layer microneedle patch based on methacrylate gelatin and sodium hyaluronate, prepared according to the following method:

[0050] (1) Preparation of raw material solution for the inner layer of the microneedle tip

[0051] Microneedle tip inner layer raw material solution: prepare gelatin methacrylate with a mass fraction of 30% containing the therapeutic drug (triamcinolone acetonide, concentration of 20 mg / mL) as the microneedle tip inner layer raw material solution, and apply it to the inner layer of the microneedle tip. Add 2-hydroxy-2-methylpropiophenone with a volume fraction of 1% to the raw material solution to form a microneedle raw material solution to be cured and place it in the dark. The raw material solution of the inner layer of the microneedle tip is cured.

[0052] (2) Prepare the raw material solution of the microneedle backing layer and the raw material solution of the outer layer of the microneedle tip

[0053] Microneedle tip outer layer...

Embodiment 2

[0059] A double-layer microneedle patch based on polyethylene glycol diacrylate and polyvinylpyrrolidone, prepared according to the following method:

[0060] (1) Preparation of raw material solution for the inner layer of the microneedle tip

[0061] Microneedle tip inner layer raw material solution: prepare a polyethylene glycol diacrylate with a mass fraction of 20% containing a therapeutic drug (dexamethasone, concentration of 20mg / mL) as a microneedle tip inner layer raw material solution, and apply it to the microneedle tip. 2-hydroxy-2-methylpropiophenone with a volume fraction of 1% is added to the inner layer raw material solution to form a microneedle raw material solution to be cured and placed in the dark. The inner layer raw material solution of the microneedle tip to be cured is irradiated with ultraviolet light Polymerization means that the inner layer of the microneedle tip is solidified from the raw material solution.

[0062] (2) Prepare the raw material sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com