Microcapsule as well as preparation method and application thereof

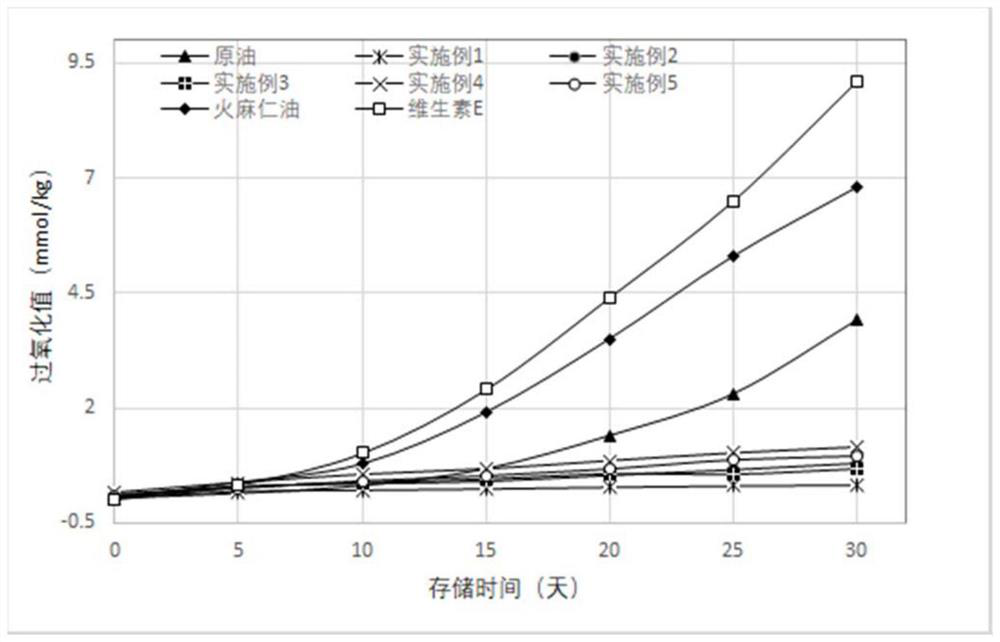

A technology for microcapsules and wall materials, applied in the field of microcapsules and their preparation, can solve the problems of difficulty in uniformly adding water-soluble products, limitations in wide application, poor stability, etc., and achieve three indicators of lowering blood lipids, improving immunity and resistance The effect of oxidative denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a microcapsule, and the formula of the microcapsule is shown in Table 1.

[0051] Table 1

[0052] name mass percentage OSA starch 50% Inulin 10% hemp oil 20% Vitamin E 20%

[0053] The preparation method of the microcapsules comprises the following steps:

[0054] (1) Mix OSA starch, inulin and water in proportion (the solid content is about 20%), heat to 50°C, and stir evenly to obtain a wall material solution;

[0055] (2) mix the hemp seed oil, vitamin E and the wall material solution in proportion, stir and mix well; homogenize 3 times with a pressure of 180bar, and then homogenize 3 times with a pressure of 550bar to obtain an emulsion;

[0056] (3) The emulsion is spray-dried at a temperature of 50° C., the inlet air temperature is 170° C., the outlet air temperature is 80° C., and the feeding rate is 0.5 L / h to obtain the microcapsules.

[0057] The measured water content of the microcapsules wa...

Embodiment 2

[0059] The present embodiment provides a microcapsule, and the formulation of the microcapsule is shown in Table 2.

[0060] Table 2

[0061] name mass percentage OSA starch 34% Maltodextrin 33% hemp oil 30% Vitamin E 3%

[0062] The preparation method of the microcapsules comprises the following steps:

[0063] (1) Mix OSA starch, maltodextrin and water in proportion (the solid content is about 20%), heat to 60°C, and stir evenly to obtain a wall material solution;

[0064] (2) mixing hemp seed oil, vitamin E and the wall material solution in proportion, stirring and mixing; homogenizing 2 times at a pressure of 250 bar, and then homogenizing 5 times at a pressure of 400 bar to obtain an emulsion;

[0065] (3) The emulsion is kept at a temperature of 60°C for spray drying (SD-1500 sprayer dryer, Shanghai Wodi Intelligent Assembly Co., Ltd.), the air inlet temperature is 220°C, and the air outlet temperature is 70°C, The feed rate was...

Embodiment 3

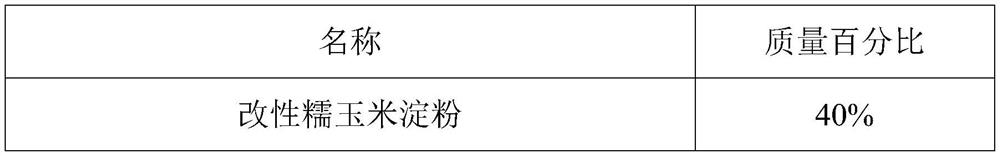

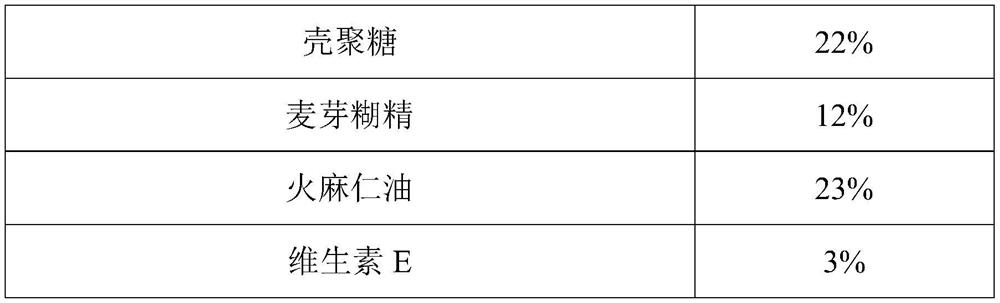

[0068] The present embodiment provides a microcapsule, and the formulation of the microcapsule is shown in Table 3.

[0069] table 3

[0070] name Proportion Modified tapioca starch 40% Chitosan 40% hemp oil 16% Vitamin E 4%

[0071] The preparation method of the microcapsules comprises the following steps:

[0072] (1) Mix the modified tapioca starch and chitosan with water in proportion (the solid content is about 20%), heat to 60°C, and stir evenly to obtain a wall material solution;

[0073] (2) mix hemp seed oil, vitamin E and the wall material solution in proportion, stir and mix evenly; homogenize 3 times with a pressure of 220bar, and then homogenize 5 times with a pressure of 400bar to obtain an emulsion;

[0074] (3) The emulsion was kept at a temperature of 55°C for spray drying (SD-1500 sprayer dryer, Shanghai Wodi Intelligent Assembly Co., Ltd.), the air inlet temperature was 220°C, and the air outlet temperature was 80°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pov | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com