Method for passivating tin oxide/perovskite interface layer of perovskite solar cell by magnesium iodide

A solar cell, magnesium iodide technology, applied in circuits, electrical components, electrical solid devices, etc., can solve problems that have not been proved by research reports, and achieve the effect of reducing defect concentration, improving conductivity, current and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

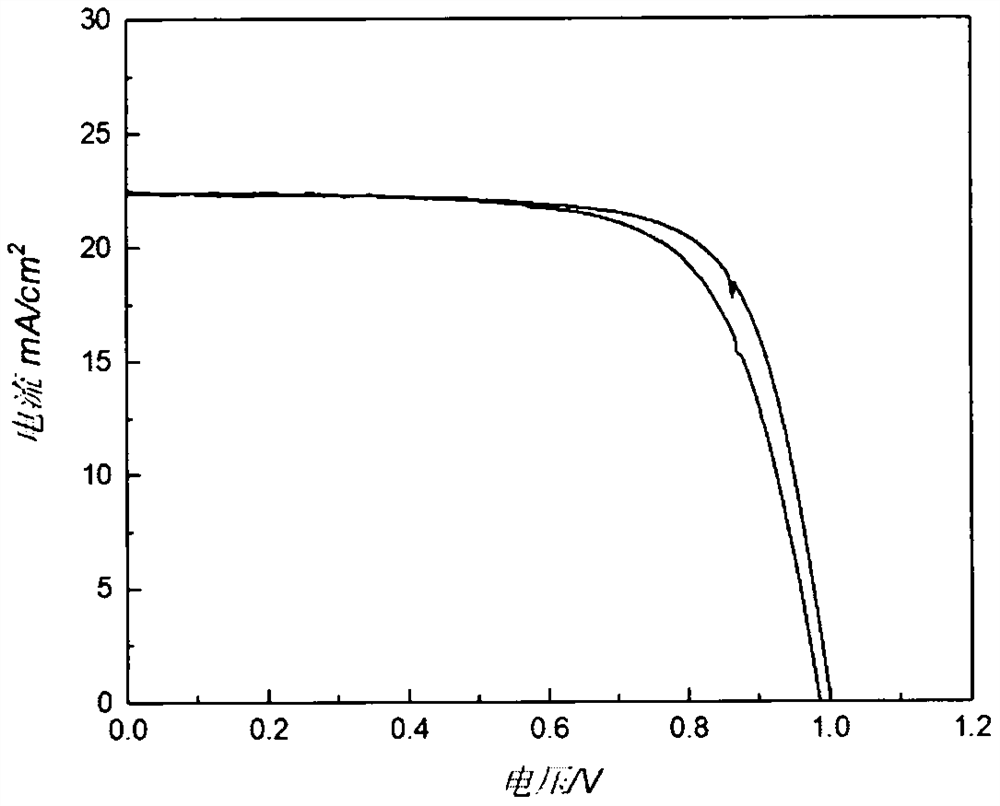

Embodiment 1

[0018] This embodiment provides a method for introducing and preparing divalent magnesium ions at the interface of the electron transport layer / perovskite layer. Cut the ITO glass into a size of 15mm×20mm, and 4mm×20mm of it is etched with zinc powder and 2M dilute hydrochloric acid. After waiting for 5 minutes, rinse with clean water. Clean the glass surface with a lint-free cloth or cotton and dish soap. Put the small pieces of ITO glass into the glass cleaning rack for cleaning in turn, add deionized water, acetone, and absolute ethanol for ultrasonic cleaning for 20 minutes, and tape the cleaned ITO conductive glass with ultraviolet ozone for 30 minutes. with SnO 2 Aqueous solution (15% SnO 2 Aqueous gel: deionized water = 1:4), filtered before use. Spin coating the prepared SnO on the spin coater 2 Aqueous solution, rotating speed 3000rpm for 20s, then annealed at 180°C for 30min on a heating plate, and then cooled to room temperature. The ethanolic magnesium iodide ...

Embodiment 2

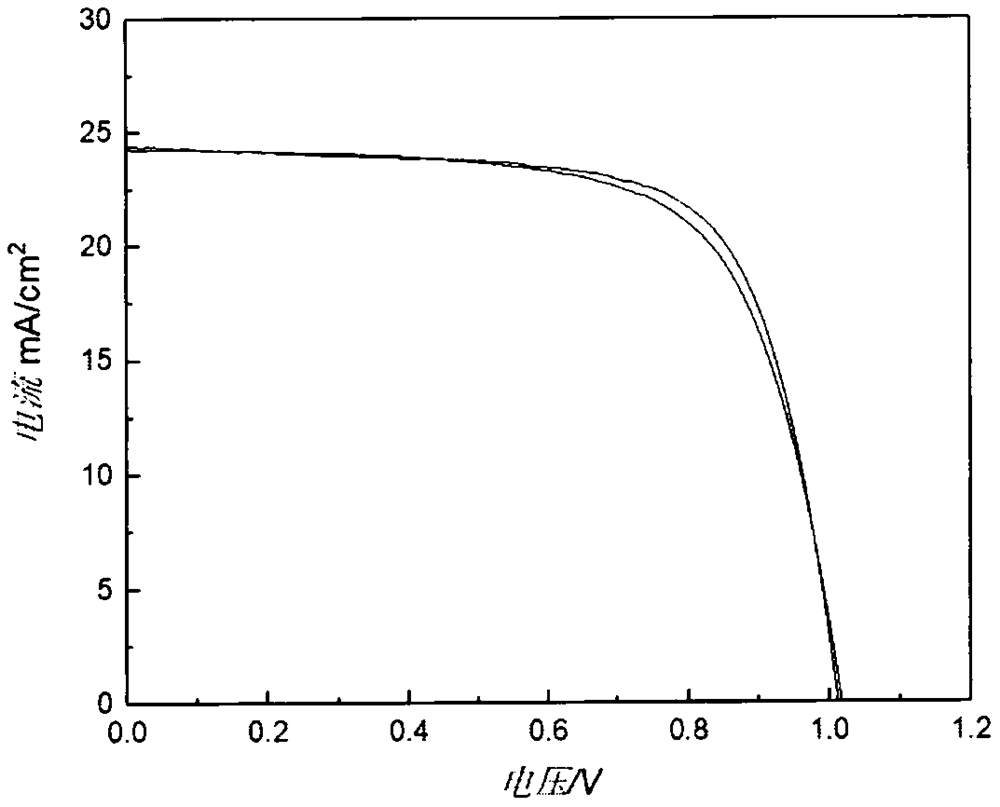

[0020] This embodiment provides a method for introducing and preparing divalent magnesium ions at the interface of the electron transport layer / perovskite layer. Cut the ITO glass into a size of 15mm×20mm, and 4mm×20mm of it is etched with zinc powder and 2M dilute hydrochloric acid. After waiting for 5 minutes, rinse with clean water. Clean the glass surface with a lint-free cloth or cotton and dish soap. Put the small pieces of ITO glass into the glass cleaning rack for cleaning in turn, add deionized water, acetone, and absolute ethanol for ultrasonic cleaning for 20 minutes, and tape the cleaned ITO conductive glass with ultraviolet ozone for 30 minutes. with SnO 2 Aqueous solution (15% SnO 2 Aqueous gel: deionized water = 1:4), filtered before use. Spin coating the prepared SnO on the spin coater 2 Aqueous solution, rotating speed 3000rpm for 20s, then annealed at 180°C for 30min on a heating plate, and then cooled to room temperature. The ethanolic magnesium iodide ...

Embodiment 3

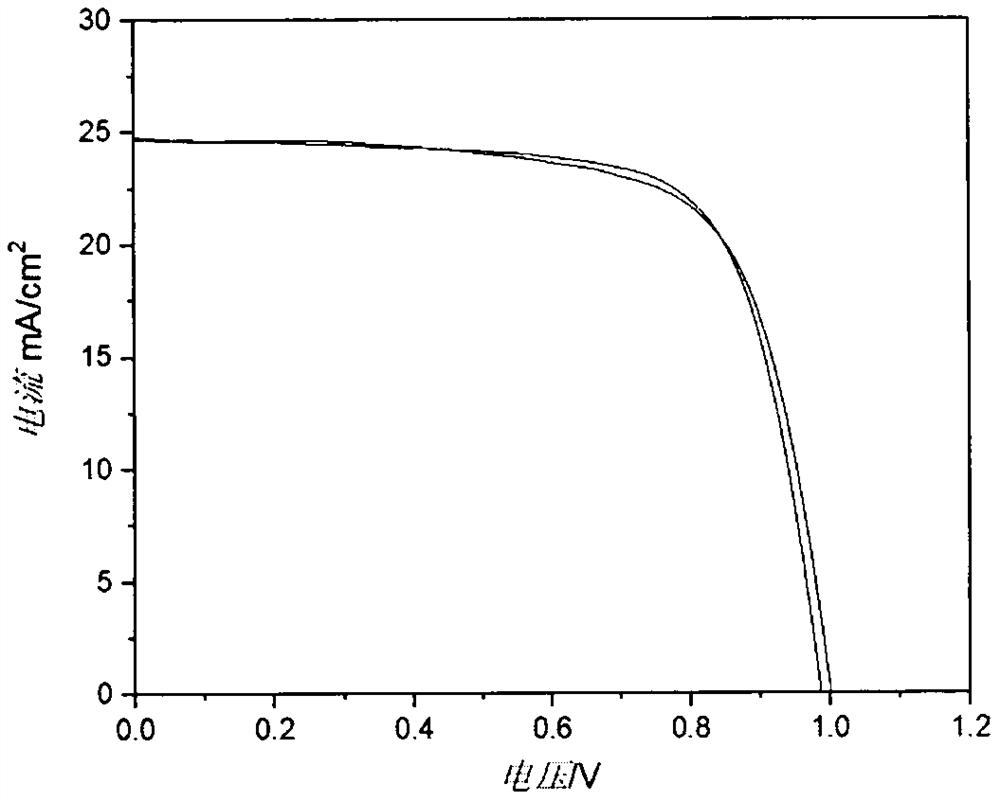

[0022] This embodiment provides a method for introducing and preparing divalent magnesium ions at the interface of the electron transport layer / perovskite layer. Cut the ITO glass into a size of 15mm×20mm, and 4mm×20mm of it is etched with zinc powder and 2M dilute hydrochloric acid. After waiting for 5 minutes, rinse with clean water. Clean the glass surface with a lint-free cloth or cotton and dish soap. Put the small pieces of ITO glass into the glass cleaning rack for cleaning in turn, add deionized water, acetone, and absolute ethanol for ultrasonic cleaning for 20 minutes, and tape the cleaned ITO conductive glass with ultraviolet ozone for 30 minutes. with SnO 2 Aqueous solution (15% SnO 2 Aqueous gel: deionized water = 1:4), filtered before use. Spin coating the prepared SnO on the spin coater 2 Aqueous solution, rotating speed 3000rpm for 20s, then annealed at 180°C for 30min on a heating plate, and then cooled to room temperature. The ethanolic magnesium iodide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com