Environment-friendly energy-saving industrial waste gas combustion treatment device and control method thereof

A technology for industrial waste gas and treatment device, which is applied in the field of environmental protection and energy saving industrial waste gas combustion treatment device and its control field, can solve problems such as affecting the efficiency of waste gas combustion treatment, and achieve the effects of saving energy, improving combustion efficiency and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

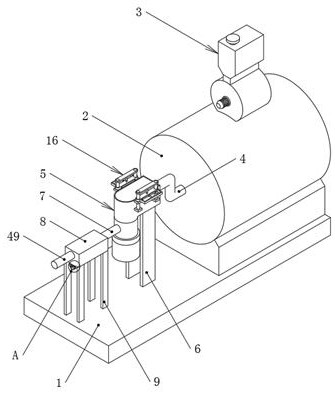

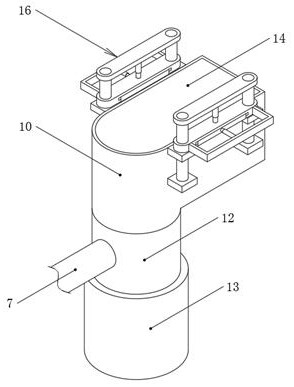

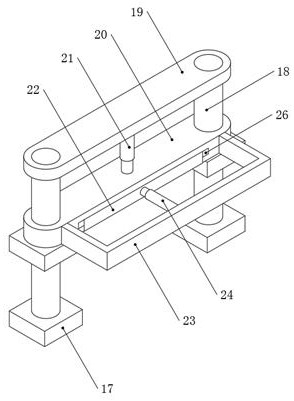

[0038] like figure 1 As shown, the present invention is an environmental protection and energy-saving type industrial waste gas combustion treatment device, comprising a base 1 and a waste gas combustion cylinder 2 arranged on the base 1 for burning industrial waste gas. The catalyst dosing mechanism 3, the end of the exhaust gas combustion cylinder 2 is connected with a filter slag discharge member 5 for filtering industrial waste gas through the first connecting pipe 4, and the filter slag discharge member 5 is arranged on the base 1 through the first bracket 6 , the filter slag discharge member 5 is connected with a waste gas heating filter cartridge 8 for pre-drying industrial waste gas through the second connecting pipe 7, and the waste gas heating filter cartridge 8 is arranged on the top of the base 1 through the second bracket 9, and the waste gas heating filter cartridge 8 An air inlet pipe 493 is provided on one end of the upper part 8 away from the second connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com