Calcium carbide purified ash treatment method and device

A treatment method and technology for purifying ash, which are applied in the directions of cement production and process efficiency improvement, etc., can solve the problems of not dealing with the magnesium content of purified ash, air pollution of combustion gas, adverse effects of cement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

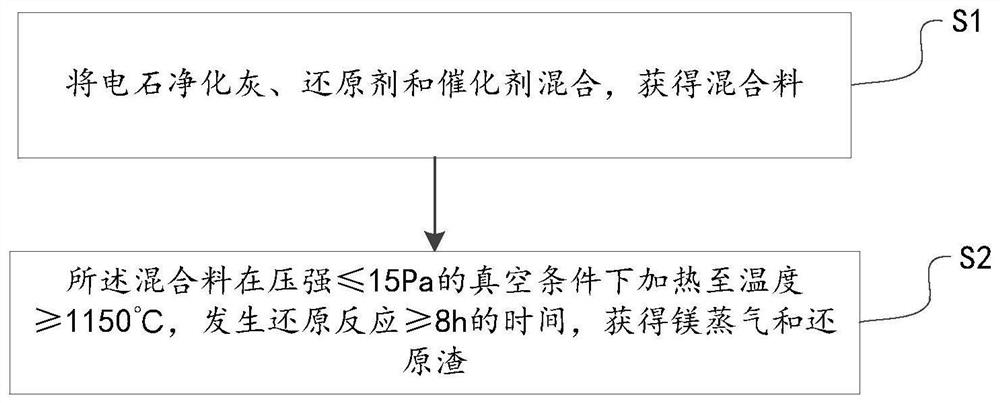

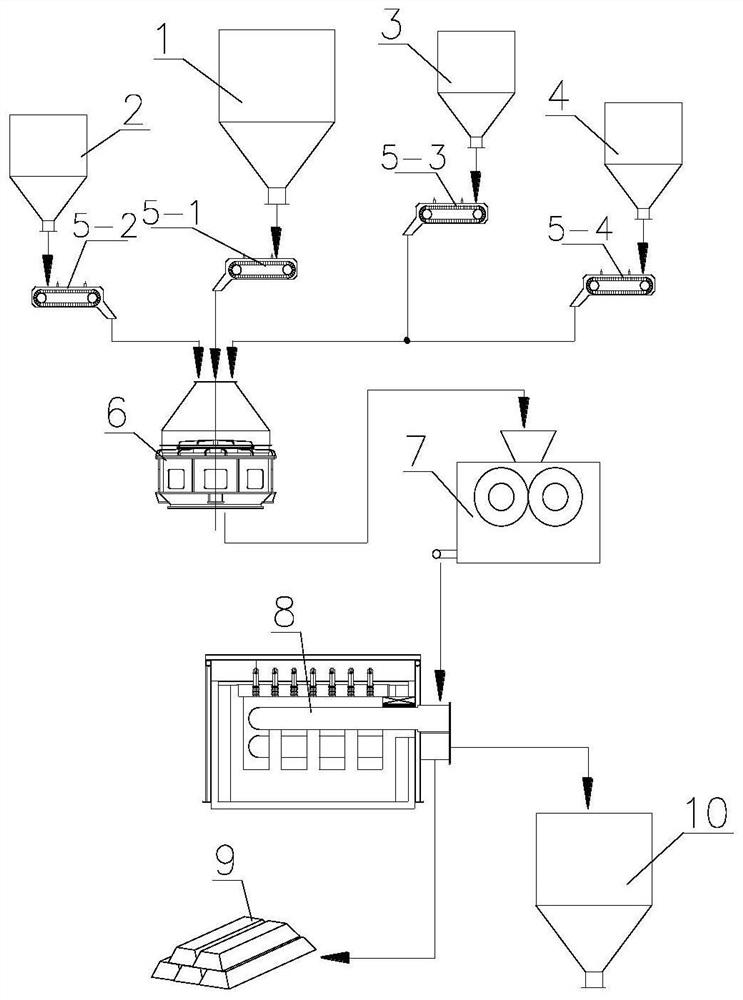

[0044] As an implementation manner of the examples of the present invention, the mixture of calcium carbide purified ash, reducing agent and catalyst to obtain a mixture includes:

[0045] The calcium carbide purified ash, reducing agent and catalyst are mixed and pelletized to obtain a mixture with a particle size of 20-40mm.

[0046] Ball making can increase the effective contact area between raw materials, provide the kinetic conditions of reduction reaction, promote the reduction reaction, shorten the reduction reaction time, and improve production efficiency; and the ball will not loose after the reaction is over, so the reduction reaction process The gaps between the balls provide channels for the diffusion of magnesium vapor generated by reduction, which is beneficial to the collection of magnesium vapor. By making balls, the shape of the obtained mixture may be spherical, ellipsoidal, or apricot-shaped, so the particle size here can be understood as the maximum length ...

Embodiment 1

[0064] Embodiment 1 provides a kind of processing method of calcium carbide purification ash, specifically as follows:

[0065] The composition (mass fraction) is MgO: 37.36%, CaO: 40.9%, SiO 2 : 8.12%, the rest is purified ash of impurities, combined with quicklime obtained by calcining limestone, standard 75# ferrosilicon, CaF 2 The mass fraction is 95% fluorite, and the mass ratio is 100:30:18:1, and then evenly mixed to make a 40x25x12mm almond-shaped pellet mixture. Put 200kg of mixed material in a φ350x4000mm reduction tank and seal it; use the electric heating cylinder coil to heat the reduction tank to 1180°C, and at the same time use a vacuum unit to evacuate the inside of the reduction tank. Up to 28.6kg metal magnesium and 167kg dicalcium silicate (2CaO·SiO 2 ) main component of the reduction slag, the reduction slag is used to make cement, and metal magnesium is reused.

Embodiment 2

[0067] Embodiment 2 provides a kind of processing method of calcium carbide purification ash, specifically as follows:

[0068] The composition (mass fraction) is MgO: 35.58%, CaO: 44.69%, SiO 2 : 9.6%, the rest is purified ash of impurities, combined with quicklime obtained by calcining limestone, standard 75# ferrosilicon, CaF 2 The mass fraction is 95% fluorite, and the batching ratio is 99:26:17:1.2, and then evenly mixed to make a 40x25x12mm apricot core pellet mixture. Put 200kg of mixed material into a φ350x4000mm reduction tank and seal it; use the electric heating cylinder coil to heat the reduction tank to 1190°C, and at the same time use a vacuum unit to evacuate the inside of the reduction tank. The vacuum degree is controlled at 15Pa, and the reduction is kept for 9 hours. 28.1kg metal magnesium and 169kg dicalcium silicate (2CaO·SiO 2 ) main component of the reduction slag, the reduction slag is used to make cement, and metal magnesium is reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com