Low-loss spinel microwave ferrite material and preparation method thereof

A ferrite material and spinel technology, which is applied in the field of low-loss spinel microwave ferrite material and its preparation, can solve the problem of inability to prepare composite substrates by co-firing, increased material loss in the transition zone, and large material loss and other problems, to achieve the effect of wide optional range, small electromagnetic loss, and adjustable power capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A low-loss spinel microwave ferrite material whose main phase structure is a spinel structure and whose chemical formula is Ni 1-a-d+e-g Zn a In b Dy c Co d Sn e Mn f Cu g Fe 2-b-c-2e-f-δ O 4 , where: a=0.1, b=0.2, c=0.02, d=0, e=0.1, f=0.04, g=0, δ=0.01.

[0036] Its preparation method is as follows:

[0037] 1. Formulated according to the compositional formula Ni 1-a-d+e-g Zn a In b Dy c Co d Sn e Mn f Cu g Fe 2-b-c-2e-f-δ O 4 , where: a=0.1, b=0.2, c=0.02, d=0, e=0.1, f=0.04, g=0, δ=0.01 for formula design;

[0038] 2. Weigh the materials, formula design results, calculate and weigh the various raw materials required, and the raw materials are analytically pure Fe 2 O 3 , NiO, ZnO, In 2 O 3 , SnO 2 , Dy 2 O 3 , MnCO 3 ;

[0039] 3. In the first ball milling, the weighed raw materials are mixed into the ball mill tank, and the balls and diluent are added. The diluent is deionized water, and the raw materials are wet mixed and ball mille...

Embodiment 2

[0048] A low-loss spinel microwave ferrite material whose main phase structure is a spinel structure and whose chemical formula is Ni 1-a-d+e-g Zn a In b Dy c Co d Sn e Mn f Cu g Fe 2-b-c-2e-f-δ O 4 , where: a=0, b=0.3, c=0.01, d=0.01, e=0, f=0.06, g=0, δ=0.06.

[0049] The preparation method is as follows:

[0050] 1. Formulated according to the compositional formula Ni 1-a-d+e-g Zn a In b Dy c Co d Sn e Mn f Cu g Fe 2-b-c-2e-f-δ O 4 , where: a=0, b=0.3, c=0.01, d=0.01, e=0, f=0.06, g=0, δ=0.06 for formula design;

[0051] 2. Weigh the materials, formula design results, calculate and weigh the various raw materials required, and the raw materials are analytically pure Fe 2 O 3 , NiO, In 2 O 3 , Co 2 O 3 , Dy 2 O 3 , MnCO 3 ;

[0052] 3. In the first ball milling, the weighed raw materials are mixed into the ball mill tank, and the balls and diluent are added, and the diluent is deionized water.

Embodiment 3

[0061] A low-loss spinel microwave ferrite material whose main phase structure is a spinel structure and whose chemical formula is Ni 1-a-d+e-g Zn a In b Dy c Co d Sn e Mn f Cu g Fe 2-b-c-2e-f-δ O 4 , where: a=0.1, b=0.1, c=0.01, d=0.01, e=0, f=0.1, g=0.1, δ=0.1.

[0062] Its preparation method is as follows:

[0063] 1. Formulated according to the compositional formula Ni 1-a-d+e-g Zn a In b Dy c Co d Sn e Mn f Cu g Fe 2-b-c-2e-f-δ O 4 , where: a=0.1, b=0.1, c=0.01, d=0.01, e=0, f=0.1, g=0.1, δ=0.1 for formula design;

[0064] 2. Weigh the materials, formula design results, calculate and weigh the various raw materials required, and the raw materials are analytically pure Fe 2 O 3 , NiO, ZnO, In 2 O 3 , Co 2 O 3 , Dy 2 O 3 , CuO, MnCO 3 ;

[0065] 3. In the first ball milling, the weighed raw materials are mixed and put into the ball mill tank, and the balls and diluent are added.

[0066]4. Pre-sintering, drying the slurry, passing through ...

PUM

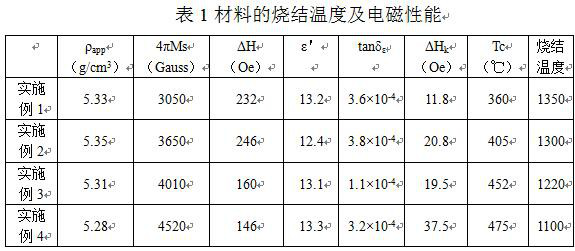

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com