Preparation method and application of aluminum tin phosphate molecular sieve catalyst

A technology of aluminum tin phosphate and molecular sieve, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of few application fields and little research on abietic acid oxidation reaction, so as to save the distillation process. , the structure regularity and order, the effect of good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Phosphoric acid, pseudo-boehmite, tin chloride, triethylamine and terpineol were mixed, placed in a hydrothermal kettle, and subjected to microwave crystallization at 200 ° C for 3 hours. After the crystallization was completed, the product was filtered, washed, Drying and calcining at 900°C for 2 hours to obtain an aluminum tin phosphate molecular sieve catalyst, wherein the molar ratios of phosphoric acid to pseudo-boehmite, tin chloride, triethylamine and terpineol are 1.1:0.8, 1.1:0.2, and 1.1, respectively. :1.4, 1.1:50;

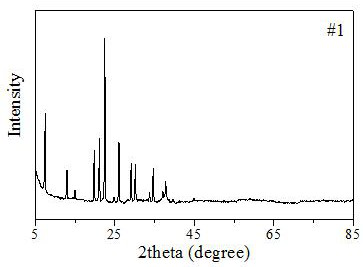

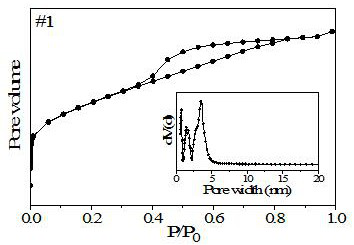

[0025] The catalyst has an AFI topology, namely SnAPO-5 (see figure 1 ), the molar substitution of Sn to aluminum is 17.6%. Average pore size 3.3nm, specific surface area 192m 2 / g, pore volume 0.27cm 3 / g (see figure 2 ).

[0026] The SnAPO-5 molecular sieve catalyst prepared in the present embodiment is used in the catalyzing reaction of L-pimamate oxidation, and specifically includes the following steps:

[0027] Take L-pimamate and pla...

Embodiment 2

[0030] Phosphoric acid, aluminum hydroxide, tin chloride, triethylamine and ethylene glycol were mixed, placed in a hydrothermal kettle, aged for 2 hours, and then microwaved at 180 °C for 5 hours. After the crystallization, the product was filtered, Washing, drying, and calcining at 300 °C for 5 h to obtain an aluminum tin phosphate molecular sieve catalyst, wherein the molar ratios of phosphoric acid to aluminum hydroxide, tin chloride, triethylamine, and ethylene glycol are 1.1:0.6, 1.1:0.4, and 1.1, respectively. :1.2, 1.1:40;

[0031] The catalyst has an AFI topology, namely SnAPO-5, the molar substitution of Sn to aluminum is 31.5%; the average pore size is 2.1 nm, and the specific surface area is 173 m 2 / g, pore volume 0.22cm 3 / g.

[0032] The SnAPO-5 molecular sieve catalyst prepared in the present embodiment is used to catalyze the abietic acid oxidation reaction, and specifically includes the following steps:

[0033] Take abietic acid and place it in a four-por...

Embodiment 3

[0036] Phosphoric acid, aluminum hydroxide, tin chloride, triethylamine and propylene glycol were mixed, placed in a hydrothermal kettle, aged for 3 hours, and then microwaved for 5 hours at 160 °C. After the crystallization, the product was filtered, washed, Drying and calcining at 600°C for 4 hours to obtain an aluminum tin phosphate molecular sieve catalyst, wherein the molar ratios of phosphoric acid to aluminum hydroxide, tin chloride, triethylamine, and propylene glycol are 1.1:0.9, 1.1:0.1, 1.1:1.1, and 1.1, respectively. :20;

[0037] The catalyst has an AFI topology, namely SnAPO-5, with a molar substitution of Sn to Al of 7.7%. Average pore size 2.4nm, specific surface area 145m 2 / g, pore volume 0.19cm 3 / g.

[0038] The SnAPO-5 molecular sieve catalyst prepared in the present embodiment is used to catalyze the oxidation reaction of levopimaric acid, and specifically includes the following steps:

[0039] Take L-pimamate and place it in a four-port reactor, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com