Manufacturing method of semiconductor laser vertical ridge structure capable of accurately controlling height

A technology of precise control and manufacturing method, applied to the structure of optical waveguide semiconductors, etc., can solve the problems of easy loose deformation, carbonization and shedding of photoresist, and failure, so as to improve the output efficiency of single-mode laser, reduce the current injection area, The effect of improving the verticality and smoothness of the side wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

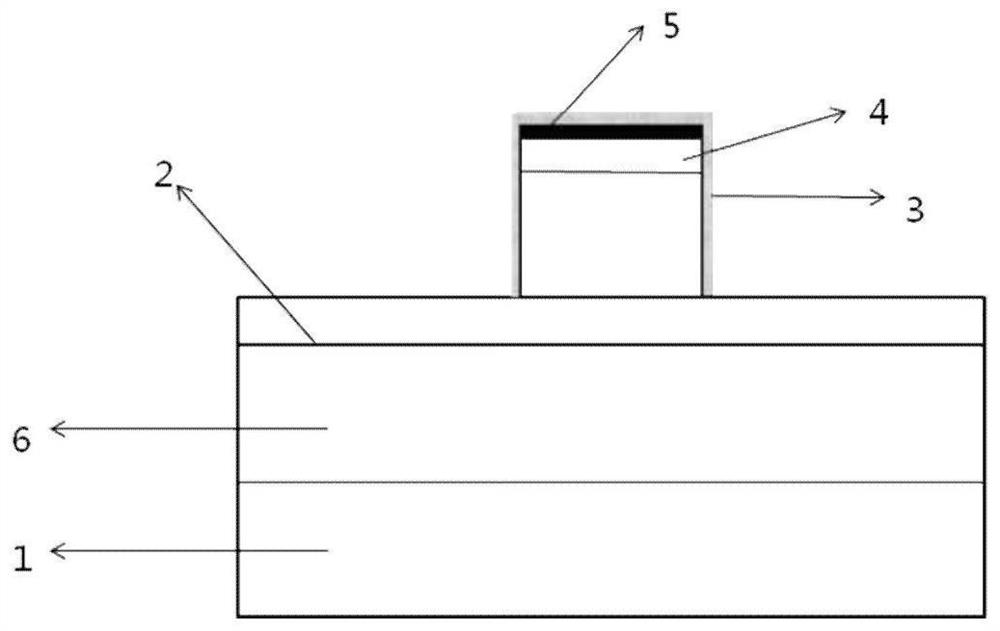

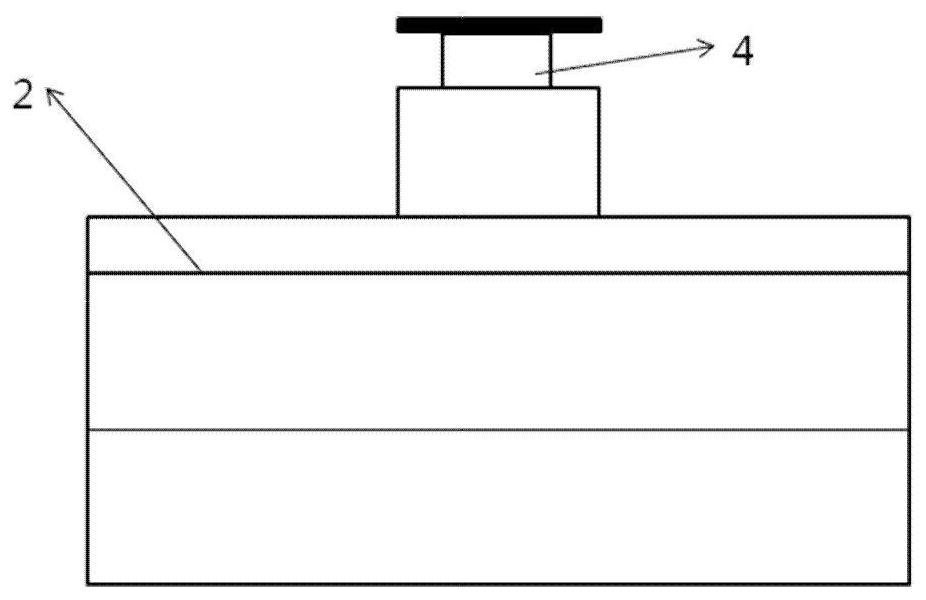

[0055] This embodiment provides a method for fabricating a vertical ridge structure of a semiconductor laser that can precisely control the height. The operation steps are as follows:

[0056] (1) The lower confinement layer, the lower waveguide layer, the active layer, the upper waveguide layer, the etching barrier layer 2, the upper confinement layer and the GaAs contact layer 4 are grown sequentially from bottom to top on the substrate 1. The etching barrier layer is selected according to the The material film layer that is difficult to corrode by hydrochloric acid solution according to the principle of natural corrosion;

[0057] (2) Deposition of SiO on the epitaxial wafer by PVD or PECVD 2 Do dry etching once mask 5, the thickness of one mask 5 is

[0058] (3) spin-coating photoresist 3 on the epitaxial wafer with the mask, the thickness of the photoresist is A periodic photoresist mask pattern adapted to the size of the ridge stripe is obtained by photolithography ...

Embodiment 2

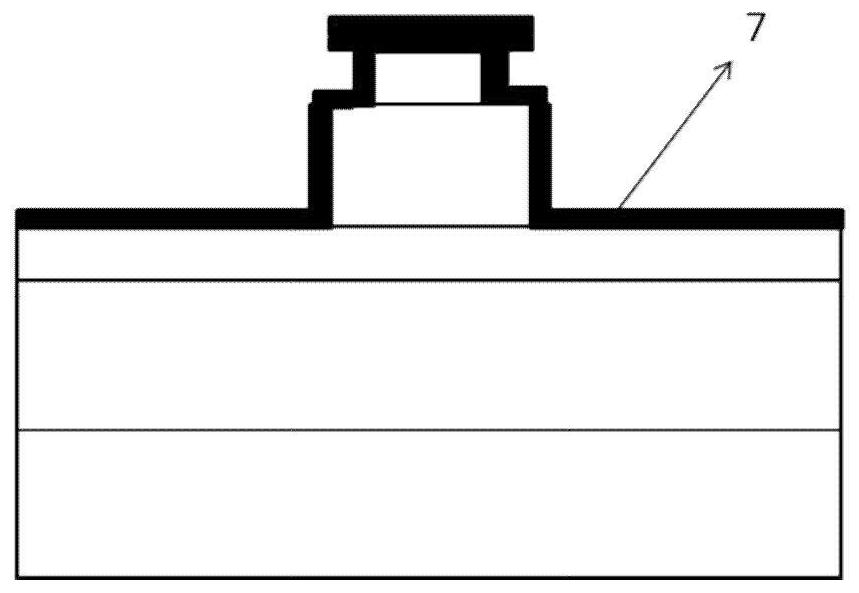

[0071] A method for manufacturing a vertical ridge structure of a semiconductor laser that can precisely control the height, the operation steps are as described in Embodiment 1, the difference is that the thickness of the primary mask in step (2) is The thickness of the photoresist in step (3) is In step (5), the etching depth is greater than that of the etching barrier layer In step (8), the thickness of the secondary mask is SiO in step (12) 2 The thickness of the current blocking layer is Thickness of photoresist in step (13)

Embodiment 3

[0073] A method for manufacturing a vertical ridge structure of a semiconductor laser that can precisely control the height, the operation steps are as described in Embodiment 1, the difference is that in step (3), the size of the ridge stripe is 5 μm in width;

[0074] Step (7), GaAs special etching solution composition and mass ratio are H 3 PO 4 :H 2 O=2:3;

[0075] In step (8), the thickness of the secondary mask is

[0076] In step (10), hydrochloric acid solution components and mass ratio are HCl:H 2 O=1:5, the corrosion time is 10-200 seconds;

[0077] In step (11), silicon dioxide etching liquid component and mass ratio are HF:H 2 O=1:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com