Method for generating alpha-glucan with specific molecular weight by utilizing three-aqueous-phase system to spontaneously regulate and control hydrolysis and application of alpha-glucan

A dextran and molecular weight technology, applied in the field of α-glucan, can solve problems such as the inability to control the molecular weight of α-glucan, and achieve the effects of mild conditions, improved economic benefits, and simple recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

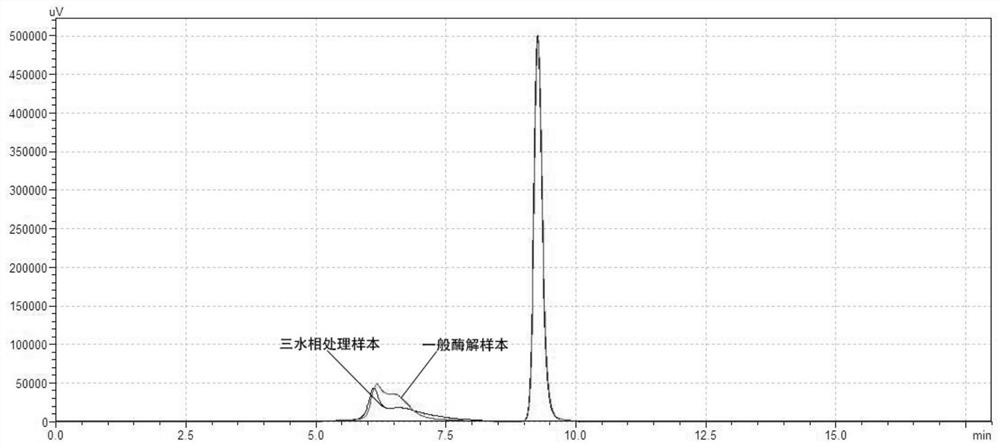

[0028] Example 1: The method for spontaneously regulating and hydrolyzing α-glucan with a weight-average molecular weight of about 100 kDa by using a three-water phase system

[0029] Reagents such as polyethylene glycol, polypropylene glycol, potassium dihydrogen phosphate, magnesium sulfate, acetic acid, and sodium acetate used in this example are all analytically pure.

[0030] The α-glucanase is derived from the Pichia pastoris engineering bacteria provided by the China Type Culture Collection, the preservation number is CCTCC No: M2013096; the Pichia pastoris engineering bacteria and the α-glucanase The preparation method of glucanase has been disclosed in patent 2013102877278. Alpha-glucan was prepared by single batch fermentation in shake flasks from Leuconostoc mesenteroides with a deposit number of GDMCC1.473 (Leuconostoc mesenteroides was purchased from the Guangdong Provincial Microbial Culture Collection Center), and the specific fermentation process was a 5L ferme...

Embodiment 2

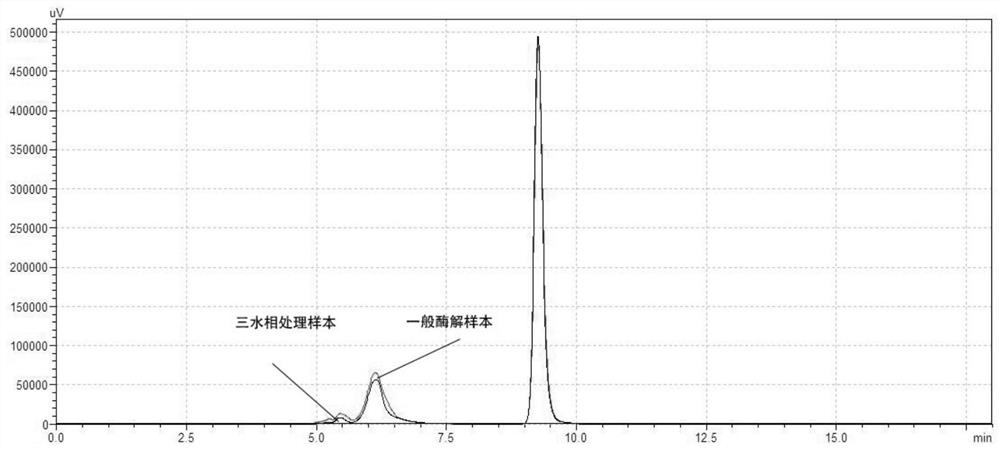

[0037] Embodiment 2: Utilize the method for spontaneously regulating and hydrolyzing the α-glucan with a weight-average molecular weight of about 500kDa by using the three-water system

[0038] Reagents such as polyethylene glycol, polypropylene glycol, potassium dihydrogen phosphate, sodium chloride, ammonium sulfate, sodium sulfate, magnesium sulfate, acetic acid, and sodium acetate used in this example are all analytically pure.

[0039] The glucanase is derived from the Pichia pastoris engineering bacteria provided by the China Type Culture Collection, the preservation number is CCTCC No: M2013096; the Pichia pastoris engineering bacteria and α-glucans with the preservation number CCTCC NO: 2013096 The preparation method of carbohydrase has been disclosed in patent 2013102877278. The α-glucan was purchased from Leuconostoc mesenteroides with the deposit number GDMCC1.473 (from the Guangdong Provincial Microbial Culture Collection). The specific fermentation process is: 5L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com