Lubricating and plugging filtrate reducer for drilling fluid and preparation method of lubricating and plugging filtrate reducer

A technology of fluid loss control agent and drilling fluid, which is applied in the field of drilling fluid, can solve the problems of ineffective fluid loss control, poor environmental protection, environmental impact, etc., to improve temperature resistance and salt resistance, easy to control, and enhance plugging performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

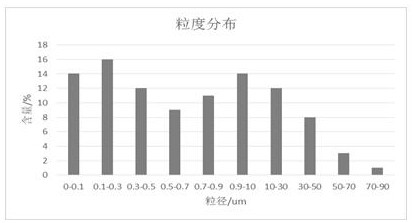

Image

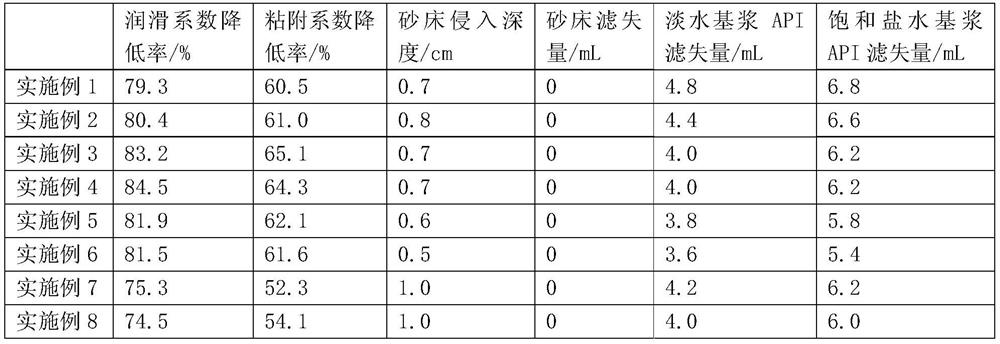

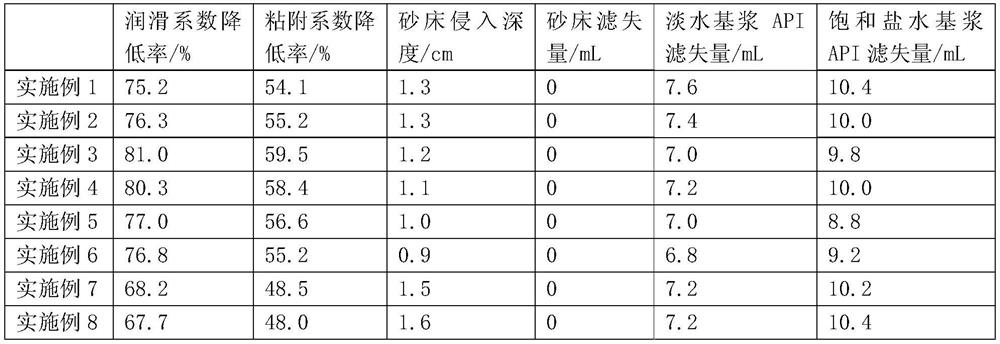

Examples

specific Embodiment 1

[0017] The lubricating plugging fluid loss control agent for drilling fluid is prepared according to the following method:

[0018] (1) Oil phase preparation:

[0019] Under normal temperature conditions, add 70 parts of white oil and 30 parts of paraffin into the reaction kettle, slowly add 15 parts of compound emulsifier under stirring at 90 r / min, and stir for 50 min to obtain an oil phase, which is for later use;

[0020] (2) Water phase preparation:

[0021] Add 80 parts of water to another reaction kettle, turn on stirring, the rotating speed is 90r / min, stir for 30min, then slowly add 8 parts of acrylic acid, 9 parts of acrylamide, 8 parts of 2-acrylamido-2-methylpropanesulfonic acid parts, 6 parts of styrene, 0.6 part of graphene oxide, adjust the pH value to 7, stir for 50min to obtain an aqueous phase, for subsequent use;

[0022] (3) Aggregation:

[0023] The water phase obtained in step (2) was slowly added to the oil phase obtained in step (1), the stirring spe...

specific Embodiment 2

[0024] The lubricating plugging fluid loss control agent for drilling fluid is prepared according to the following method:

[0025] (1) Oil phase preparation:

[0026] Under normal temperature conditions, add 70 parts of white oil and 30 parts of paraffin into the reaction kettle, slowly add 20 parts of compound emulsifier under stirring at 90 r / min, and stir for 50 min to obtain an oil phase, which is for later use;

[0027] (2) Water phase preparation:

[0028] Add 80 parts of water to another reaction kettle, turn on stirring, the rotating speed is 90r / min, stir for 30min, then slowly add 9 parts of acrylic acid, 10 parts of acrylamide, 9 parts of 2-acrylamido-2-methylpropanesulfonic acid parts, 7 parts of styrene, 0.8 parts of graphene oxide, adjust the pH value to 7, stir for 50min to obtain an aqueous phase, for subsequent use;

[0029] (3) Aggregation:

[0030] The water phase obtained in step (2) was slowly added to the oil phase obtained in step (1), the stirring spe...

specific Embodiment 3

[0031] The lubricating plugging fluid loss control agent for drilling fluid is prepared according to the following method:

[0032] (1) Oil phase preparation:

[0033] Under normal temperature conditions, add 80 parts of white oil and 20 parts of paraffin into the reaction kettle, slowly add 15 parts of compound emulsifier under stirring at 90 r / min, and stir for 50 min to obtain an oil phase, which is for later use;

[0034] (2) Water phase preparation:

[0035] Add 90 parts of water to another reaction kettle, turn on stirring, the rotating speed is 90r / min, stir for 40min, then slowly add 8 parts of acrylic acid, 9 parts of acrylamide, 8 parts of 2-acrylamido-2-methylpropanesulfonic acid parts, 6 parts of styrene, 0.6 part of graphene oxide, adjust the pH value to 7, stir for 60min to obtain an aqueous phase, for subsequent use;

[0036] (3) Aggregation:

[0037] The water phase obtained in step (2) was slowly added to the oil phase obtained in step (1), the stirring spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com