System for repairing organic contaminated soil by soil ventilation-vertical desorption furnace

A technology of organic pollution and soil, applied in the restoration of polluted soil, etc., can solve the problems that cannot meet the complexity and diversity of organic pollutants, no organic pollution soil remediation system, small specific heat capacity, etc., to prevent secondary pollution , The equipment process is simple and effective, and the effect of low investment cost

Active Publication Date: 2012-07-04

NANJING AGRICULTURAL UNIVERSITY

View PDF1 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this patent, the temperature of the hot air is generally lower than 350°C, and because the specific heat capacity of the air is small, the temperature of the soil after heating will not be too high, so it can only treat benzene and benzene series with a low boiling point in the polluted soil, which cannot meet the requirements of the city. Requirements for Complexity and Diversity of Organic Pollutants in Contaminated Sites

Retrieval of relevant literature shows that no literature on the organic contaminated soil remediation system with a structure similar to the present invention has been found before the patent application date

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

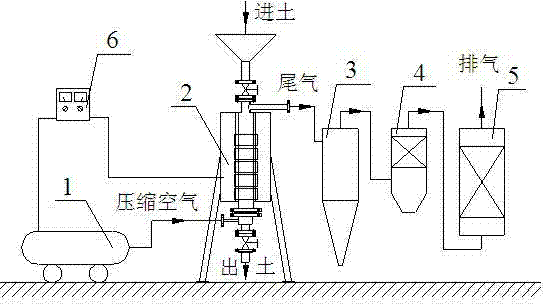

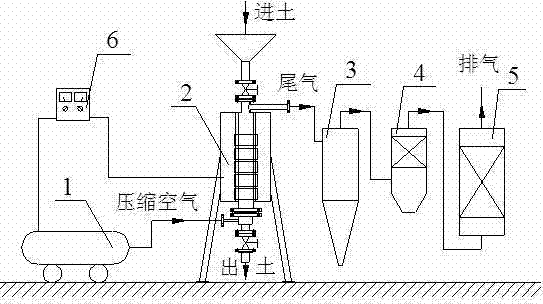

The invention provides a system for repairing the organic contaminated soil by a soil ventilation-vertical desorption furnace, comprising a thermal desorption system, a tail gas treatment system and a control system, wherein the thermal desorption system consists of an air compressor 1 and a vertical desorption furnace 2; the tail gas treatment process consists of a cyclone dust collector 3, a dehumidifier 4 and an adsorption tower 5; and the control system 6 can realize the effective control of the soil heating temperature. The system can be used for repairing the organic contaminated soil in which the main contaminants are volatile / semivolatile.

Description

technical field [0001] The present invention relates to a system for remediating soil polluted by volatile / semi-volatile organic compounds, more specifically a soil ventilation-vertical desorption furnace for remediating organic polluted soil by using soil ventilation and electric heating methods soil system. Background technique In recent years, with the acceleration of industrialization and urbanization in our country, urban planning, urban expansion, adjustment of functional areas and urban layout, a large number of polluting enterprises have been relocated, and a large number of polluted industrial sites have been left behind. The resulting environmental pollution accidents and The harm to human health has become a major factor restricting the development and utilization of urban land. According to the survey, the pollutants left by the relocation of polluting enterprises mainly involve organic pollutants and heavy metals, among which volatile / semi-volatile organic po...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B09C1/00B09C1/06

Inventor 孔火良高彦征张攀

Owner NANJING AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com