Magnetic separation and deinking method for waste paper

A waste paper and magnetic separation technology, which is applied in waste paper processing, paper making, paper recycling, etc., can solve the problems of increased difficulty in deinking and difficulty in achieving the desired effect, so as to save raw materials and energy, benefit the national economy, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

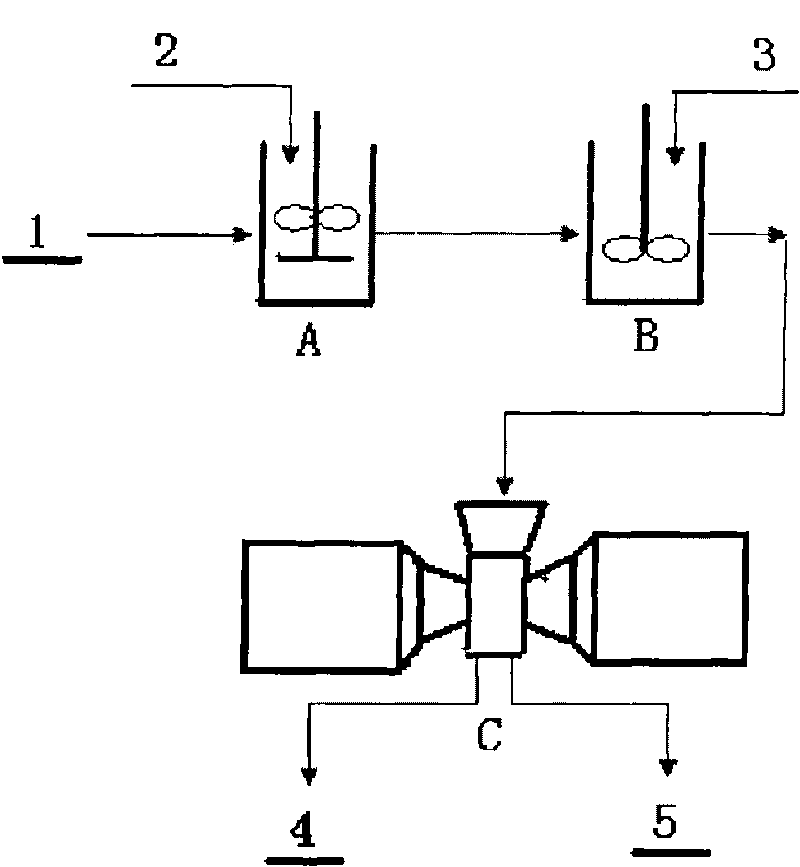

Image

Examples

Embodiment 1

[0030] The raw material of waste paper is waste copy paper, the magnetite is magnetite, and the coagulant is modified polyacrylamide, which is modified by quaternization of polyacrylamide, with a molecular weight of 5 million to 20 million. First make polyacrylamide into a dispersion solution with a certain mass fraction, heat it and keep it at a constant temperature, add the amine-aldehyde reaction solution made of formaldehyde and dimethylamine, stir, react, then cool, add bromoethane to quaternize Reagents, modified, and finally precipitated with acetone, the resulting reaction product is the coagulant used.

[0031] Add waste paper and 0.2wt% magnetite magnetic seeds into the pulper, then add water, sodium silicate and NaOH to pulp, wherein water is added to make the pulp concentration 10wt%, and the amount of sodium silicate is 10wt%, adjusted with NaOH pH to 7. After the waste paper is pulped, it is diluted with water to a pulp concentration of 4wt%, and 0.1wt% coagulan...

Embodiment 2~5

[0037] The raw material of waste paper is waste magazine paper. The operation method, equipment and product testing are the same as in Example 1, and the coagulant is the same as in Example 1. It is modified polyacrylamide. The specific experimental conditions and experimental results are listed in Table 2.

[0038] The experimental conditions of table 2, embodiment 2-5

[0039] Experimental conditions

Example 2

Example 3

Example 4

Example 5

Magnetic species

0.05wt%

magnetite

0.03wt%

magnetite

0.2wt%

0.1wt% artificial

Ferrite Particles

Sodium silicate

2wt%

5wt%

8wt%

10wt%

The slurry was adjusted to pH with NaOH

7

9

10

8.5

After pulping, dilute with water to a pulp concentration of

0.5wt%

2.0wt%

3.5wt%

4.0wt%

Coagulant, wt% (dry paper weight)

0.01

0.025

0.05

0.1

Coagulation time of magnetic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com