Super-smooth high-voltage cable semi-conductive internal shielding material and preparation method thereof

A high-voltage cable, semi-conductive technology, applied in the field of semi-conductive inner shielding of ultra-smooth high-voltage cables and its preparation, can solve the problem of thermal-oxidative aging, the surface finish of the cable is difficult to meet the ultra-smooth requirements, the electrical properties and mechanical properties are difficult to meet the requirements at the same time, etc. problems, to achieve the effect of improving surface properties, good conductive network structure, and increasing wetting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

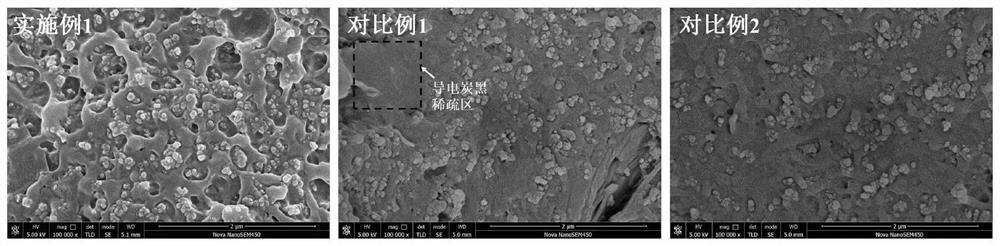

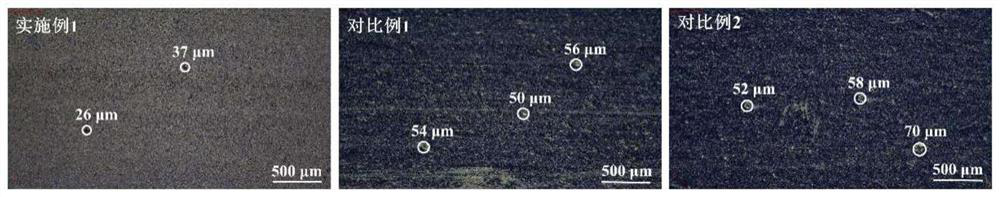

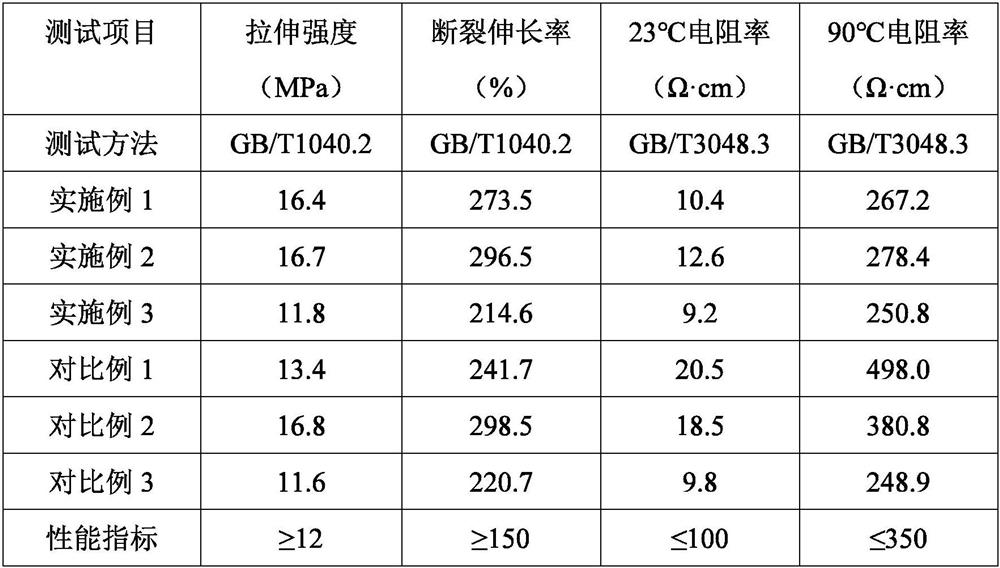

Examples

preparation example Construction

[0039] The present application also discloses a preparation method of the high-voltage cable semiconductive inner shielding material, the preparation method comprising the following steps:

[0040] (1) remove moisture from the conductive carbon black according to the weight ratio, mix it with the dispersant of the weight ratio, and carry out the dispersant coating treatment of the conductive carbon black;

[0041] (2) The conductive carbon black pretreatment obtained in step (1) is continuously mixed with the weight ratio coupling agent, lubricant part and antioxidant under a high-speed mixer, and the speed of the high-speed mixer is controlled within 100-200rpm. between. Then add the base material with the set weight ratio and continue to mix evenly at 45-50°C;

[0042] (3) the mixture obtained in step (2) is melt-extruded in a twin-screw extruder, extrusion temperature is 160° C., and the rotation speed of the main engine is 100 rpm, and then the pellets are obtained by wat...

Embodiment 1

[0044] As an embodiment of the present invention, a semi-conductive inner shielding material for an ultra-smooth high-voltage cable and a preparation method thereof are provided. The semi-conductive inner shielding material for high-voltage cables includes, in parts by weight, 63 parts of base material, 32 parts of conductive carbon black, 1 part of dispersant, 1 part of coupling agent, 1.5 parts of lubricant, 0.8 part of antioxidant, and 0.8 parts of cross-linking agent. 1.2 servings. The total number of the crosslinking agent and the antioxidant is 2 parts, and the mass ratio is 1.5:1.

[0045] The base material is EBA resin, the BA content is 17 wt %, the melt index at 190° C. and 2.16 kg is 8.5 g / min, and the elongation at break is 800%.

[0046] The conductive carbon black is high-purity conductive carbon black, the DBP absorption value is 148ml / 100g, the ash content is 0.2%, the 325-mesh sieve residue content is 6ppm, and does not contain impurity elements such as sulfu...

Embodiment 2

[0057] As a semi-conductive inner shielding material for ultra-smooth high-voltage cables in an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is that the total number of crosslinking agents and antioxidants is 2.2 parts (0.8 parts of antioxidants). , 1.4 parts of crosslinking agent), the mass ratio is 1.75:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com