Method for testing and evaluating energy consumption performance of steel-composite material anti-collision facility structure

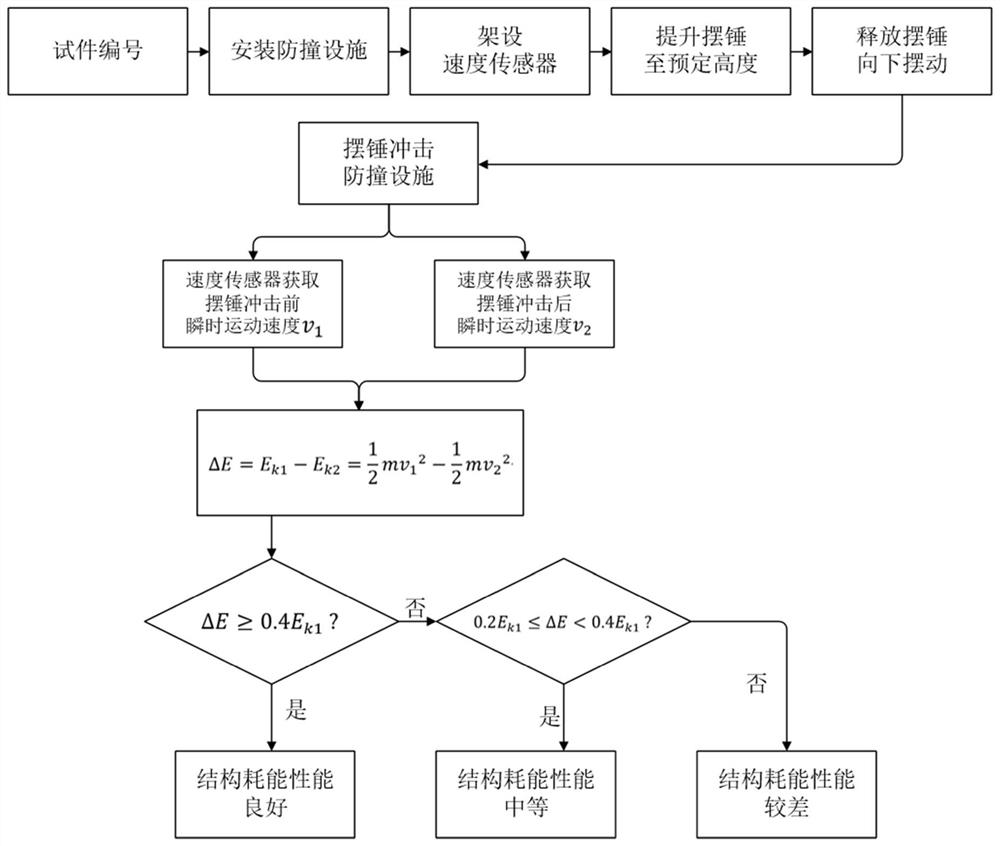

A composite material and anti-collision technology, which is applied in the testing of machine/structural components, impact testing, material analysis, etc., can solve the problems of insufficient energy consumption capacity of anti-collision facilities, affecting the safe operation of bridges, damage and destruction of pier columns, etc., to achieve The effect of data extraction and calculation is convenient, the evaluation steps are clear and easy, and the floor space is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

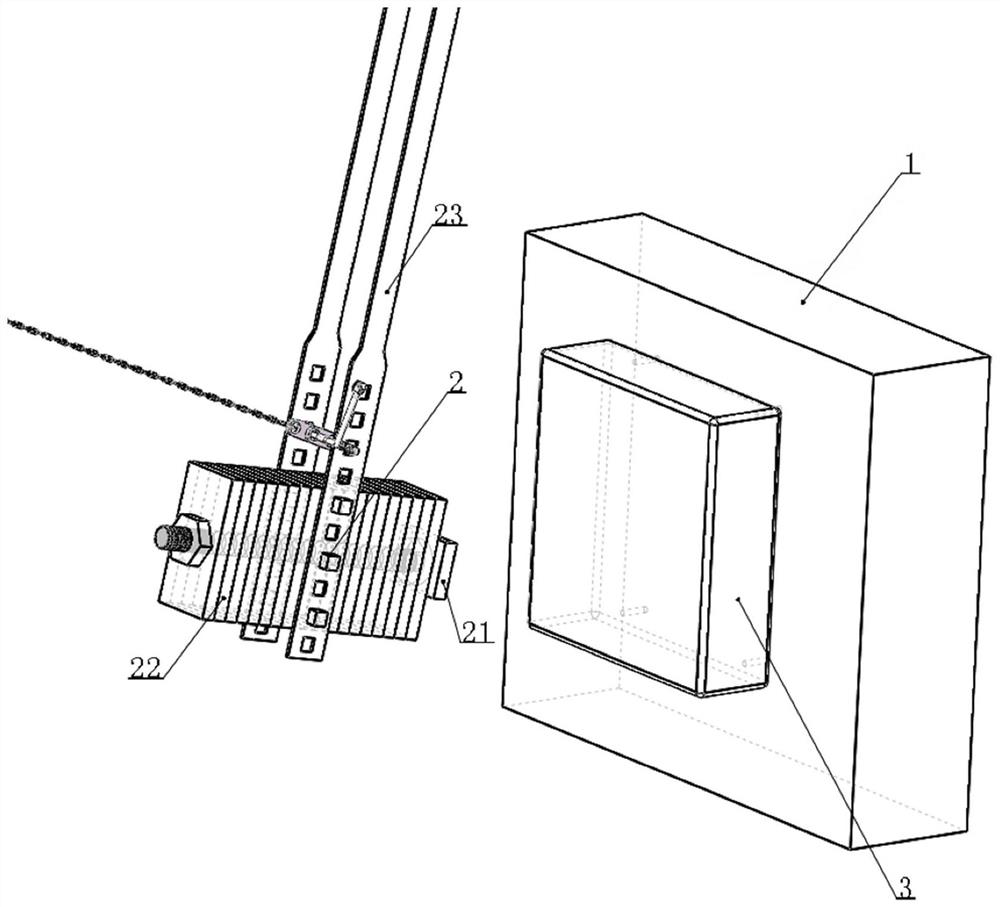

[0032] Step 1: Install a certain number of mass counterweights 22 for the pendulum device 2 to make the mass reach 1000kg.

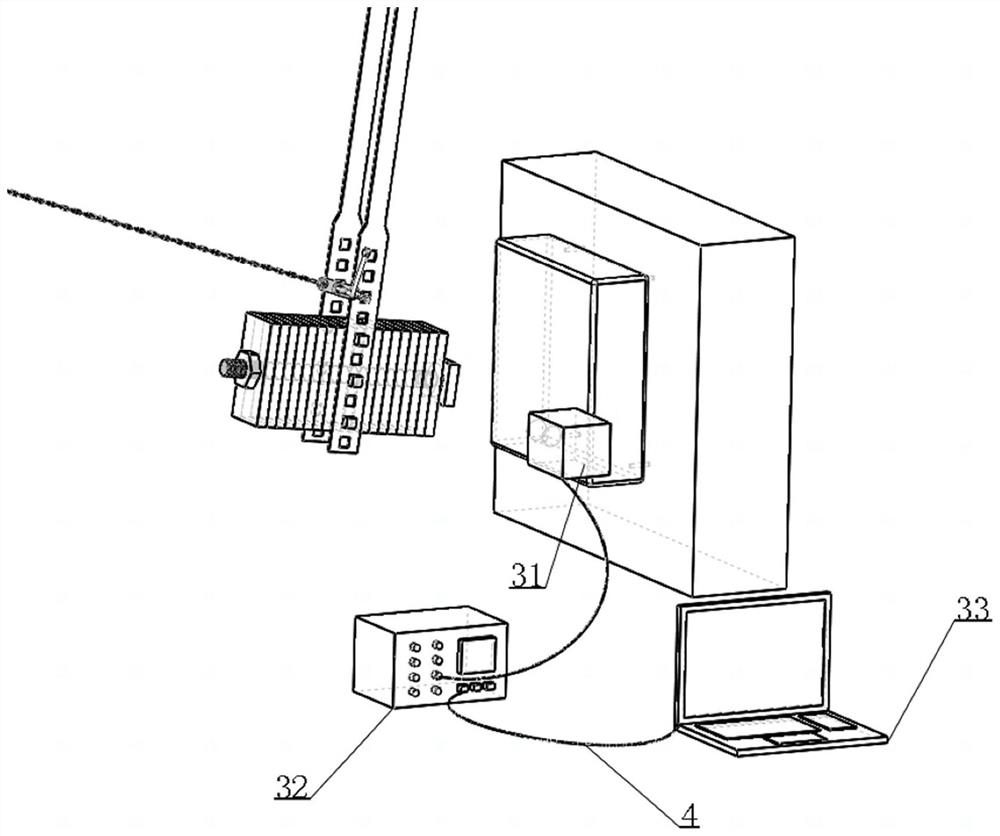

[0033] A steel-composite anti-collision facility 3 is arranged on the concrete rigid wall 1, and a speed sensor 31 is arranged at a corresponding position on the side of the concrete rigid wall 1 close to the impact point. The speed sensor 31 is a photogate speed sensor.

[0034] The data of the speed sensor 31 is transmitted to the data acquisition instrument 32, and after signal processing, enters the data storage device 33 for storage.

[0035] Step 2: Number and fix a certain type of steel-composite anti-collision facility with a thickness of 300mm; according to the structural and mechanical properties of the steel-composite anti-collision facility, select a suitable pendulum mass of 1000kg and an impact height of 0.459 m, the theoretical speed when it swings to the lowest point is 3m / s. The 1000kg pendulum is lifted to a height of 0.459m by the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com