Silicone adhesive, silicone film and backlight unit

A silicone and adhesive technology, applied in the direction of adhesive, film/sheet adhesive, film/sheet release liner, etc., can solve the problem of high transparency, low reflectivity, high visibility, low weather resistance, It is not easy to process and other problems, and achieves the effect of being conducive to double-sided bonding, high transparency and low reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

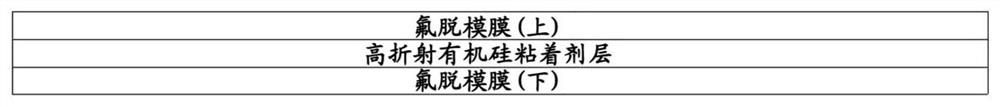

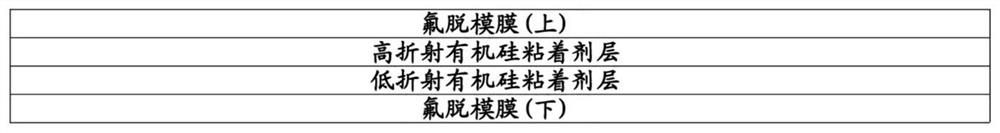

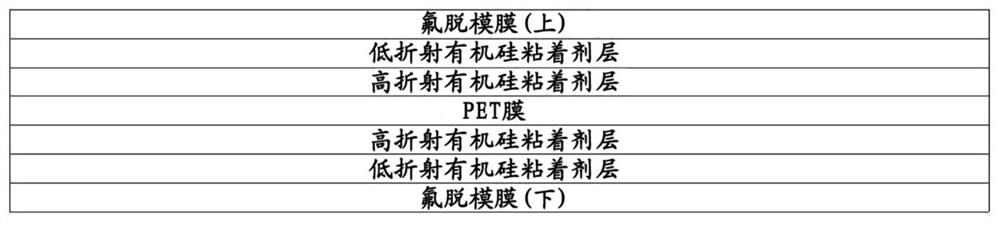

Image

Examples

Embodiment 1 ~ Embodiment 4

[0119] [Example 1] to [Example 4] and [Comparative Example 1]

[0120] The components described in the following Table 1 were uniformly mixed to manufacture a silicone adhesive. Examples 1 to 4 used the composite polymer resin represented by Chemical Formula 1. In particular, Example 1 used a composite polymer resin bonded with zirconia as a metal oxide, and Example 2 used a composite polymer resin bonded with titanium oxide. , Example 3 uses a composite polymer resin combined with zinc oxide, the catalyst uses a platinum-based catalyst, and the solvent uses toluene. Example 4 is the same as Example 1 except that the contents of catalyst and solvent are different. As Comparative Example 1, an adhesive was produced using the silsesquioxane resin of the following Chemical Formula 5 in place of the composite polymer resin represented by the Chemical Formula 1. Moreover, as Reference Example 1, in order to manufacture a low-refractive-index silicone adhesive, the adhesive was ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com