Method for improving blackness of plate surface of sheared sheep garment product

A technology for product board and sheep shearing, applied in dyeing, tanning, textiles and papermaking, etc., can solve the problems of aggravating the difficulty of sewage treatment, low absorption rate of black dyes, increasing production costs, etc. Difficulty, uniform color, full color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

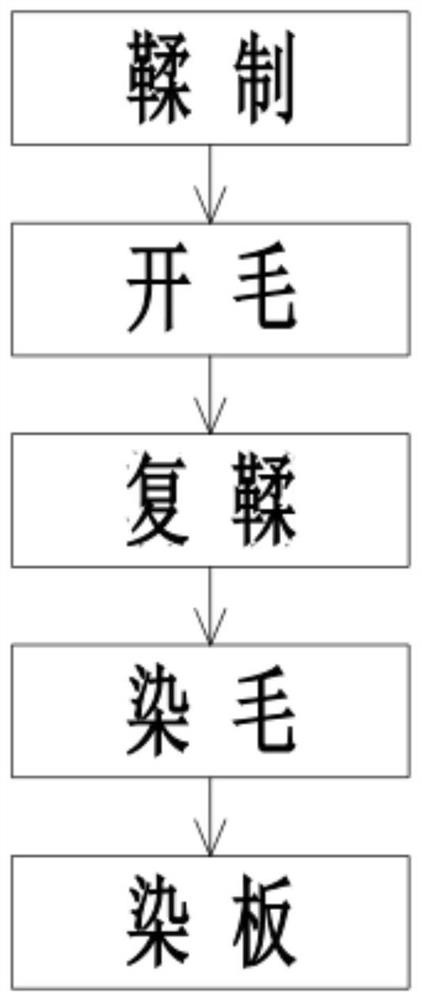

[0057] like figure 1 As shown in the figure, a method for improving the blackness of the board surface of a sheep shearling garment product includes the following steps:

[0058] 1) Add 38°C water to the inclined drum, liquid ratio 1:18, temperature 38°C, add 2g / L MgO, rotate for 30min, add 0.5g / L GC, 0.5g / L ML-N, 0.5g / L L SL, 0.5g / L TIS, 0.5g / L 55 / C rotate for 60min, add formic acid 1g / L, rotate for 20min, add chrome powder 3g / L, aluminum tanning agent ALF 2g / L, rotate for 90min, then add sodium formate 2g / L, rotate for 30min, add 0.5g / L of baking soda, rotate for 90min, adjust pH to 3.8-4.0, drain.

[0059] 2) Add 40°C water to the inclined drum, the liquid ratio is 1:18, the temperature is 38°C, add 10g / L anhydrous sodium sulfate, 2g / L ammonia water and 0.5g / L MN-L, and measure the pH after rotating for 120min For 6.5-7, let it stand, after the stand is completed, perform the transfer and stop treatment, and drain the water after the transfer and stop treatment; the stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com