A kind of preparation method of black dye

A technology of black dyes and dye monomers, applied in dyeing methods, organic dyes, textiles and papermaking, etc. It can solve the problems of poor blackness and poor hand feeling of black dyes, and achieve good hand feeling, excellent color fastness and dyeing performance , Guarantee the effect of jet blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples. For the experimental methods that do not specify specific conditions in the following examples, select according to conventional methods and conditions, or according to the product instructions.

[0021] In the embodiment of the present invention,

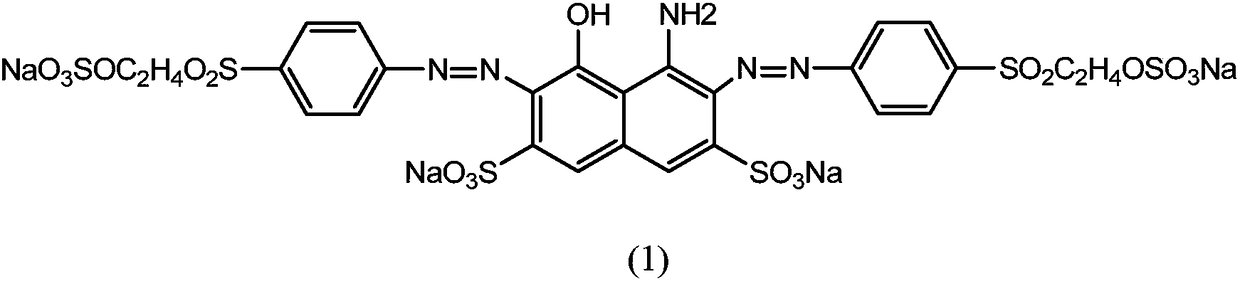

[0022] Dye monomer A is C.I. reactive black 5 (commercially available conventional product);

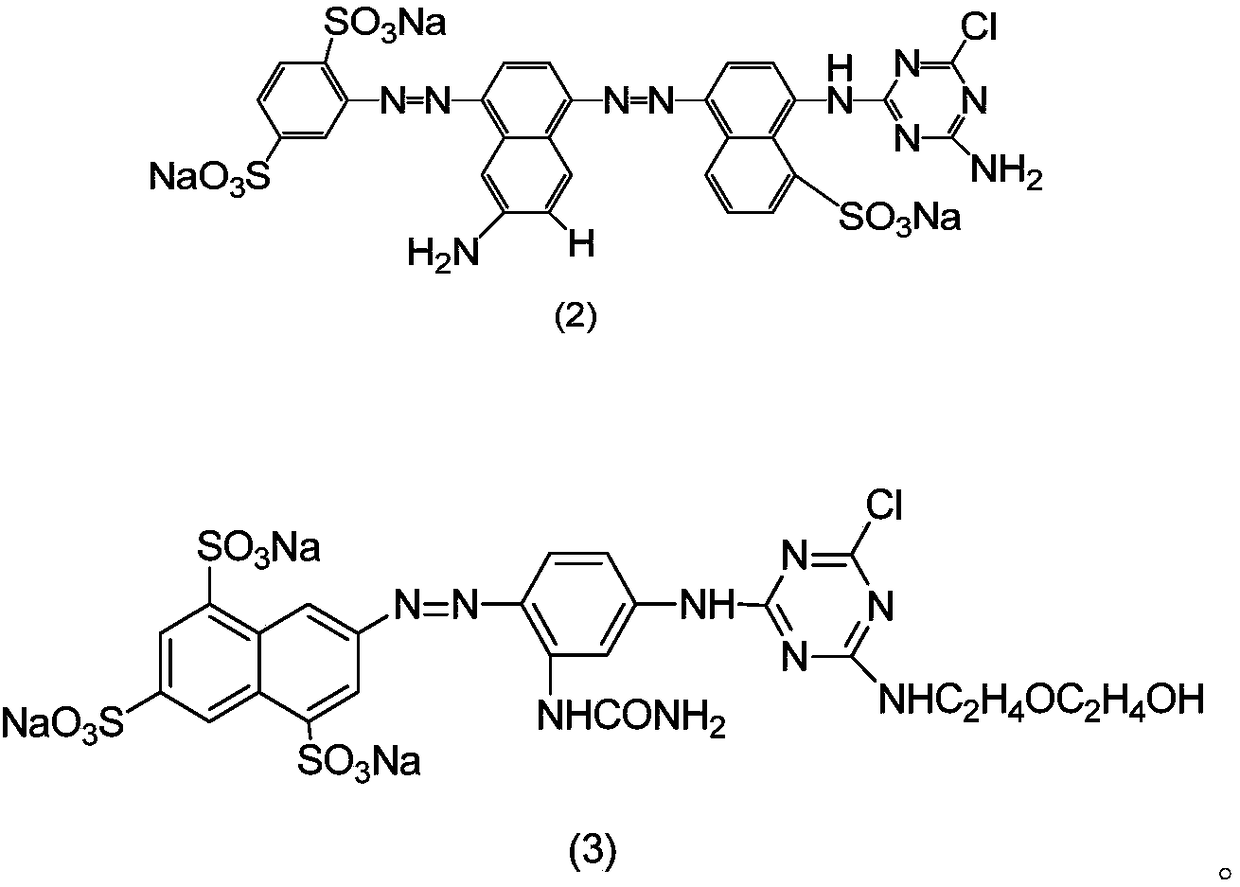

[0023] Dye monomer B is Ciba Reactive Brown P-6R;

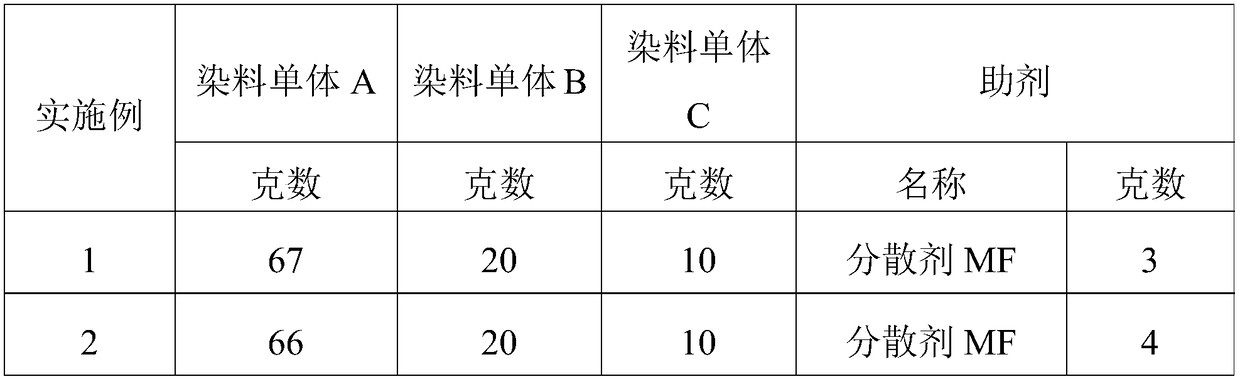

[0024] Dye monomer C is Ciba Reactive Yellow P-2RN.

[0025] Example Mix the dye monomer A, dye monomer B, dye monomer C and co-solvent, and adopt the commonly used monomer powder blending method in this industry. The powder blending needs to ensure that the lower part of the material returns to the upper part. 3 times, with a total mixing time of 3 hours. For the above mixing methods, samples should be taken from the top, middle and bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com