A kind of anti-scratch black bright PC/ABS alloy and preparation method thereof

A scratch-resistant and scratch-resistant technology, applied in the polymer field, can solve the problems of decreased impact strength of materials, decreased material toughness, whitish visual appearance, etc., and achieves good dispersibility, colorability, and scratch resistance. Good, bright looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

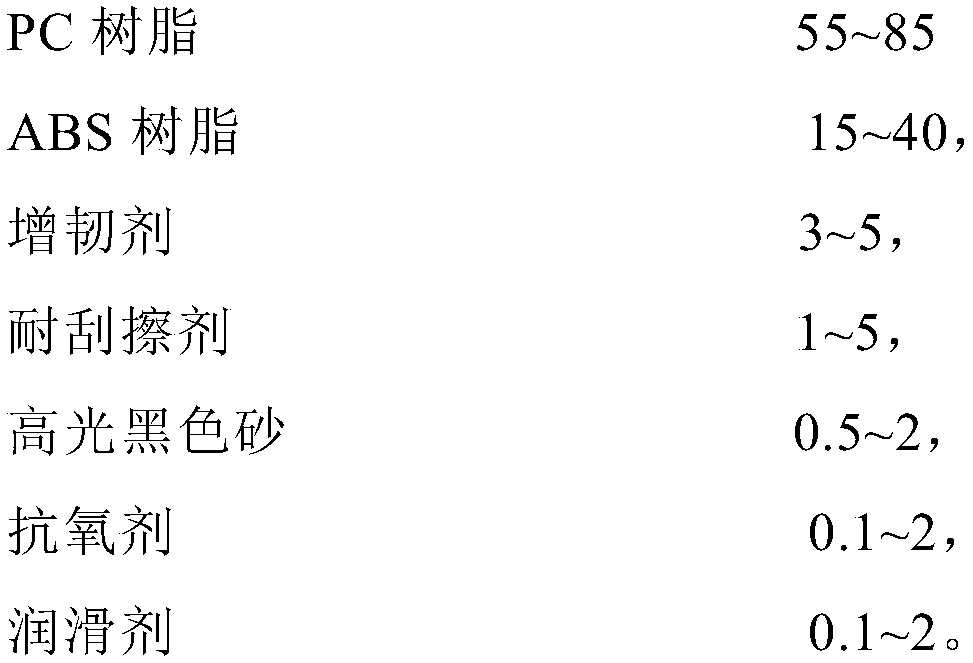

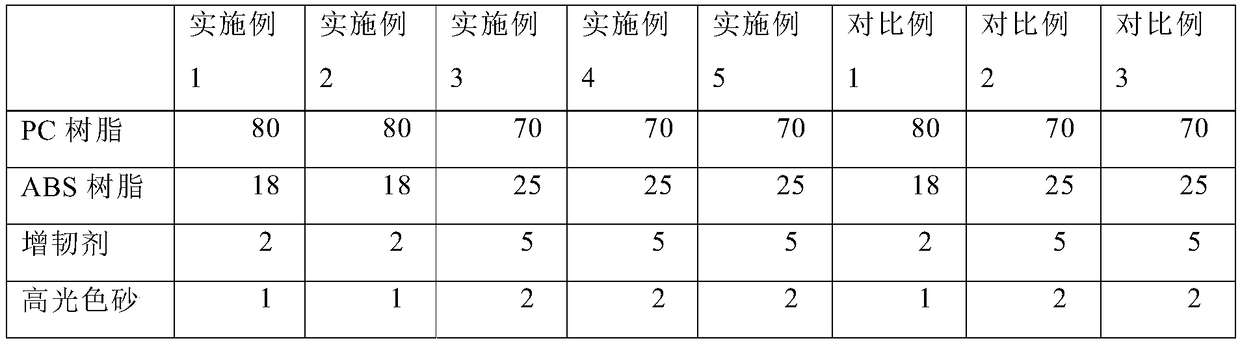

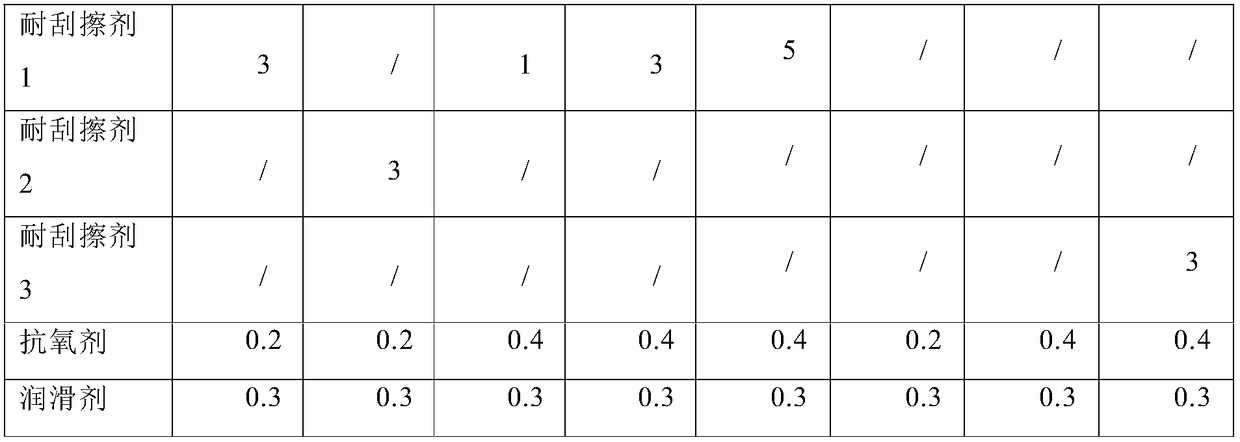

Method used

Image

Examples

Embodiment 6

[0042] A scratch-resistant black bright PC / ABS alloy, which is prepared from the following components and raw materials in parts by weight: PC resin 55, ABS resin 40, toughening agent 3, scratch-resistant agent 1, high-gloss black sand 0.5, anti-scratch Oxygen 0.1, lubricant 0.1. Wherein, the PC resin used is bisphenol A polycarbonate resin, and the melt index under the condition of 300° C. / 1.2 kg is 10 g / 10 min. The ABS resin is a graft copolymer composed of acrylonitrile-butadiene-styrene, the melt index is 15g / 10min under the condition of 220°C / 10kg, and the weight percentage of rubber is 45%. The toughening agent is a terpolymer of methyl methacrylate, butadiene and styrene. The anti-scratch agent is PE-g-SAN, in which the Mn molecular weight of the PE main chain is 2000. The high-gloss black sand is composed of carbon black and a dispersant, the weight percentage of the carbon black is greater than 90%, and the dispersant is pentaerythritol stearate. The antioxidant is...

Embodiment 7

[0047]A scratch-resistant black bright PC / ABS alloy, which is prepared by using the following components and raw materials in parts by weight: PC resin 85, ABS resin 15, toughening agent 5, scratch-resistant agent 5, high-gloss black sand 2, anti-scratch Oxygen 2, lubricant 2. The PC resin is bisphenol A polycarbonate resin, and its melt index at 300°C / 1.2kg is 22g / 10min. The ABS resin is a graft copolymer composed of acrylonitrile-butadiene-styrene, the melt index is 30g / 10min under the condition of 220°C / 10kg, and the weight percentage of rubber is 55%. The toughening agent is a terpolymer of methyl methacrylate, butadiene and styrene. The anti-scratch agent is PE-g-SAN, in which the Mn molecular weight of the PE main chain is 5000. The high-gloss black sand is composed of carbon black and a dispersant, the weight percentage of the carbon black is greater than 90%, and the dispersant is pentaerythritol stearate. The antioxidant is 3-(3,5-di-tert-butyl-4-hydroxyphenyl) n-o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com