Phenolic resin composition and its preparation method and application in the preparation of stamping die

A phenolic resin and stamping die technology, applied in the field of polymer composite materials, can solve the problems of low production efficiency, high temperature, long curing time, etc., and achieve the effect of low use cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

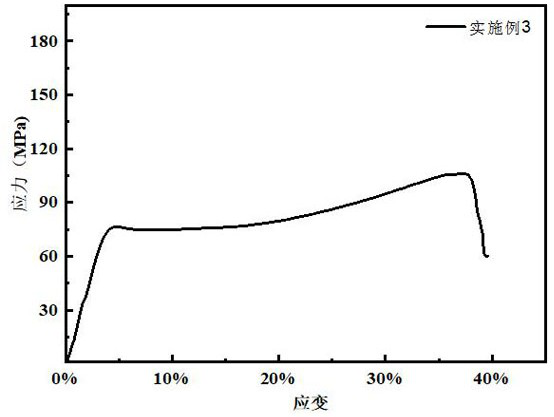

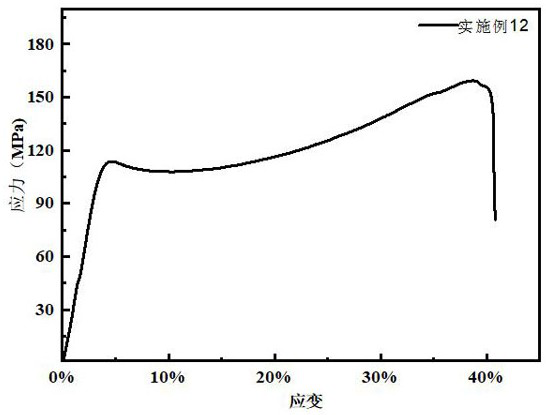

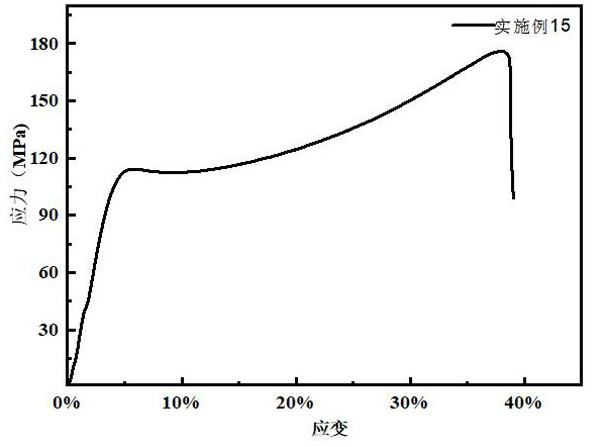

[0040] Example: A phenolic resin composition, the composition includes, according to mass g, 10~40g of phenolic resin, 10~40g of styrene-butadiene rubber, 5~12g of iron powder, 6~8g of carbon-based material, and 7g of non-ferrous metal powder. ~13g, metal oxide 0.2~3g, basalt fiber 10~13g and dispersant 2.4~5.3g. The carbon-based material is selected from carbon nanotubes and / or carbon fibers; the non-ferrous metal powder is selected from at least one of Zr, Ni or Cu; the metal oxide is Al 2 O 3 , TiO 2 , Ni 2 O 3 , Fe 3 O 2 or at least one of CoO. The modified phenolic resin is a polyimide-modified phenolic resin, and the mass ratio of the phenolic resin to the polyimide in the polyimide-modified phenolic resin is 1:0.125~2. The iron powder is selected from reduced iron powder and / or electrolytic iron powder, and the mesh number of the iron powder is selected from 800-1600 mesh. The iron powder includes 2-4 parts of 1600-mesh electrolytic iron powder, 1-3 parts of 160...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com