Device and method for preparing silicon dioxide aerogel felt and silicon dioxide aerogel felt

A technology of airgel felt and silicon dioxide, which is applied to the device for coating liquid on the surface, pretreatment of the surface, coating, etc., can solve the problems of low efficiency, long reaction cycle, increased production cost, etc., and achieve high quality , The effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

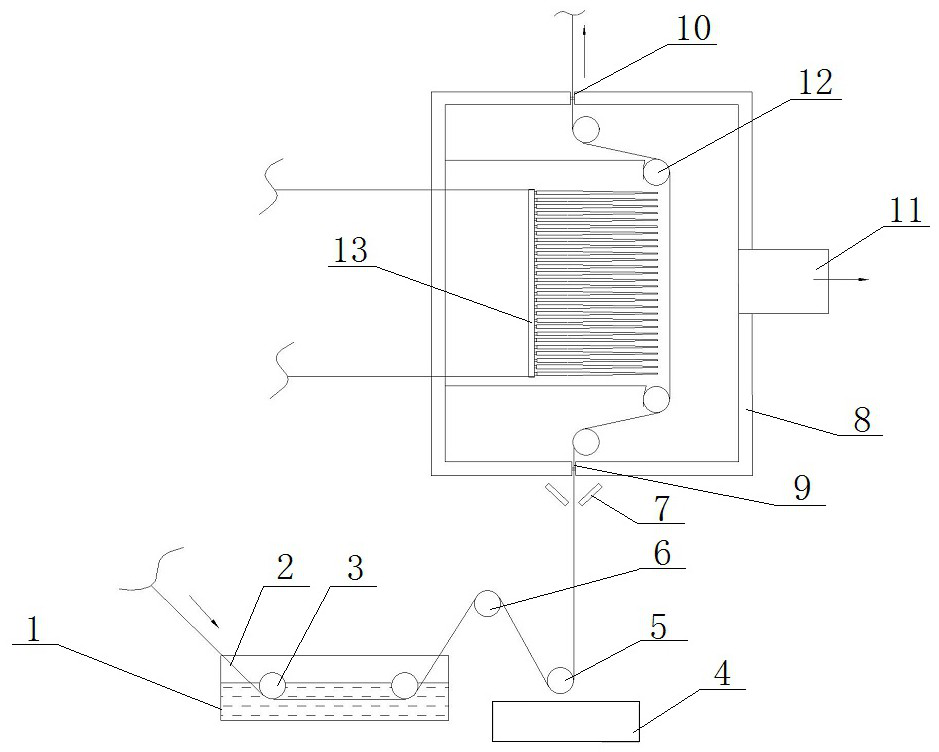

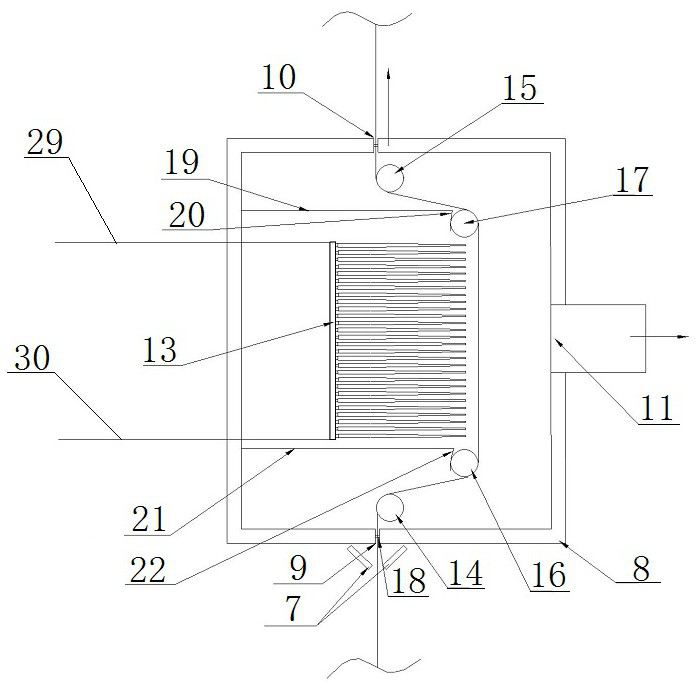

[0043] Below in conjunction with the accompanying drawings and specific embodiments, a device for preparing silica aerogel felt at atmospheric pressure of the present invention is described in further detail:

[0044] like figure 1 As shown, a device for preparing a silica aerogel felt according to the present invention includes a dipping tank 1 , a liquid collecting tank 4 , and a hydrophobic drying box 8 . Wherein, the dipping tank 1 is used to hold a sol, and in this embodiment, the sol is a silica sol. The dipping tank 1 is provided with a pressing roller 3, which is used to press the fiber mat 2 into the sol, so that the fiber mat 2 and the sol are fully combined. Roller 3, the unrolled fiber mat 2 is pressed into the dip tank by two pressing rollers 3 so that the sol in the dip tank 1 is fully impregnated on the fiber mat 2. There is a sol replenishing tank (not shown in the figure) beside the dipping tank 1, which is used to continuously replenish the sol in the dippi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com