High-temperature anti-oxidation high-strength nickel-tungsten-cobalt-chromium alloy and preparation method thereof

A high-temperature anti-oxidation, cobalt-chromium alloy technology, which is applied in the field of metal materials, can solve the problems of increased creep resistance, reduced stacking fault energy, and reduced creep rate, etc., to suppress the formation of pores and oxide inclusions, and good high-temperature oxidation resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

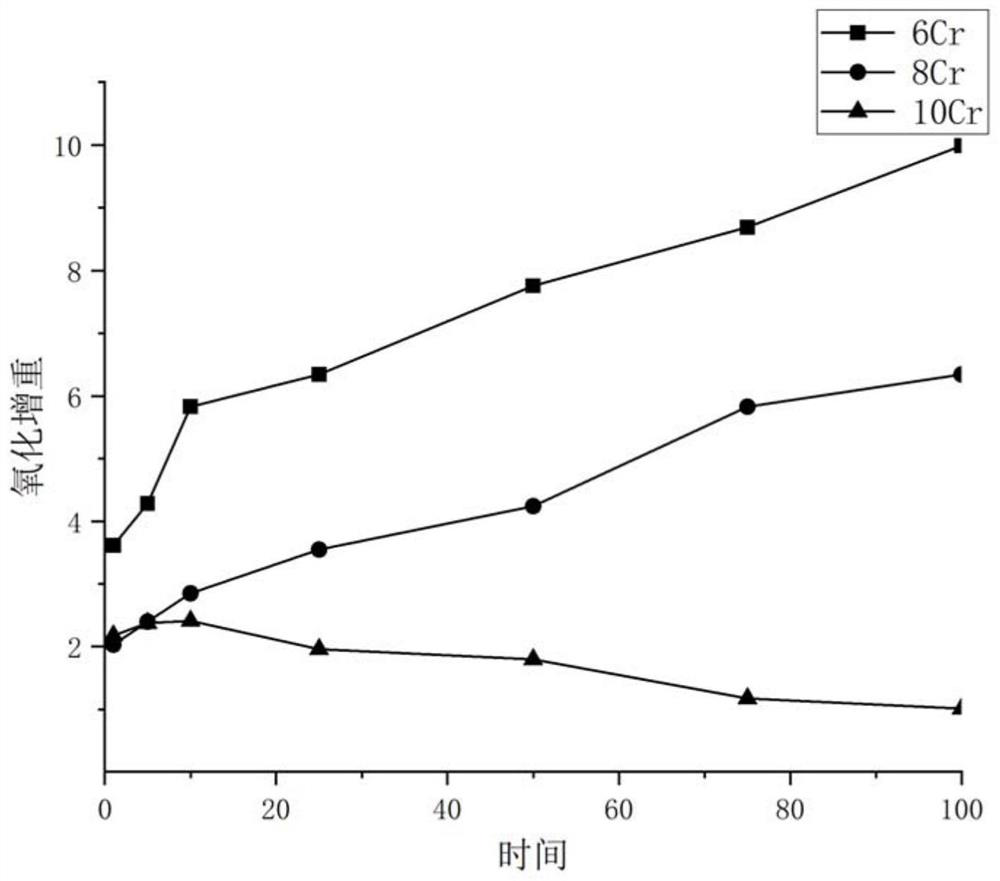

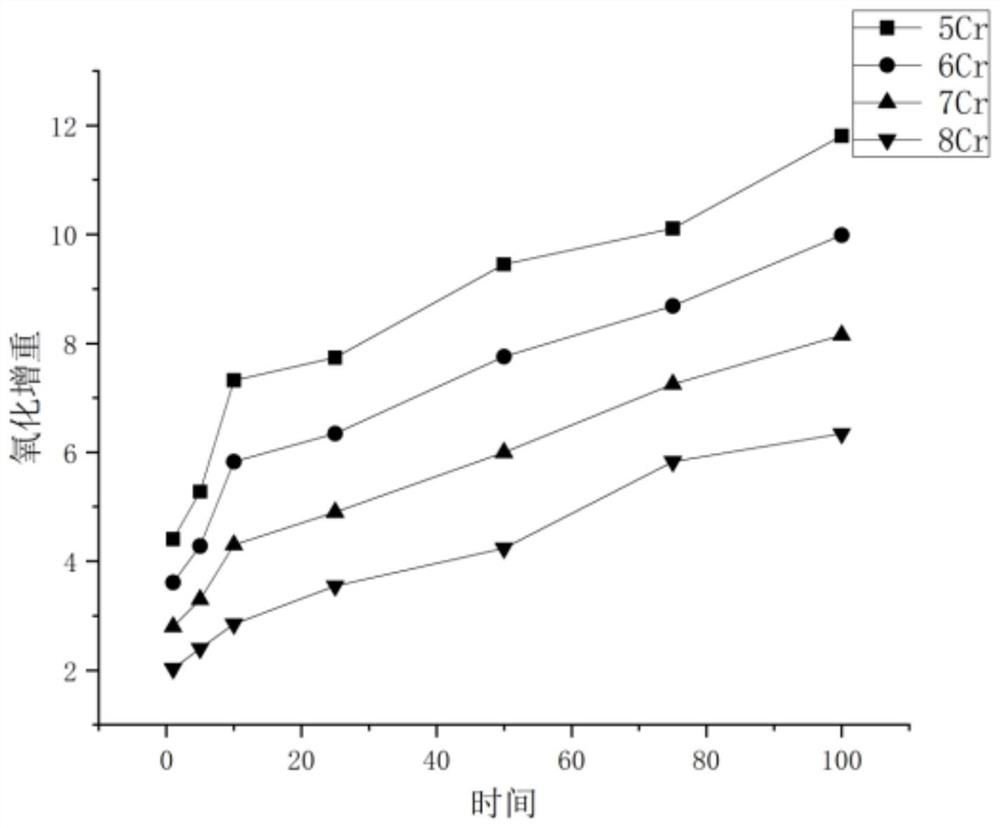

[0051] A preparation method of a high-temperature oxidation-resistant and high-strength nickel-tungsten-cobalt-chromium alloy. The chemical composition of the high-temperature oxidation-resistant and high-strength nickel-tungsten-cobalt-chromium alloy is: W: 36wt.%, Co: 15wt.%, Cr : 10wt.%, the oxygen content is controlled within 15ppm, and the balance is Ni and inevitable impurities.

[0052] The preparation method comprises the following steps:

[0053] S1, raw material preparation stage

[0054] According to the mass percentage of raw material chemical components in the high-temperature oxidation-resistant and high-strength nickel-tungsten-cobalt-chromium alloy, the ingredients are batched and weighed. The dosage of deoxidizer C is 0.06wt.% of the quality of the nickel-tungsten-cobalt-chromium alloy to obtain the prepared nickel-tungsten-cobalt alloy Chromium raw material and deoxidizer C;

[0055] S2, vacuum melting stage

[0056] The nickel-tungsten-cobalt-chromium raw...

Embodiment 2

[0065] A method for preparing a high-temperature oxidation-resistant and high-strength nickel-tungsten-cobalt-chromium alloy, wherein the chemical composition of the high-temperature oxidation-resistant and high-strength nickel-tungsten-cobalt-chromium alloy is: W: 40wt.%, Co: 18wt.%, Cr : 8wt.%, the oxygen content is controlled within 15ppm, and the balance is Ni and inevitable impurities.

[0066] The preparation method comprises the following steps:

[0067] S1, raw material preparation stage

[0068] According to the high temperature oxidation resistance and high strength nickel-tungsten-cobalt-chromium alloy, the raw material chemical components are batched and weighed according to the mass percentage. The amount of deoxidizer C is 0.07wt.% of the quality of the nickel-tungsten-cobalt-chromium alloy to obtain the prepared nickel-tungsten-cobalt alloy Chromium raw material and deoxidizer C;

[0069] S2, vacuum melting stage

[0070] The nickel-tungsten-cobalt-chromium r...

Embodiment 3

[0079] A method for preparing a high-temperature oxidation-resistant and high-strength nickel-tungsten-cobalt-chromium alloy, wherein the chemical components of the high-temperature oxidation-resistant and high-strength nickel-tungsten-cobalt-chromium alloy are: W: 38wt.%, Co: 20wt.%, Cr : 6wt.%, the oxygen content is controlled within 15ppm, and the balance is Ni and inevitable impurities.

[0080] The preparation method comprises the following steps:

[0081] S1, raw material preparation stage

[0082] According to the high temperature oxidation resistance and high strength nickel-tungsten-cobalt-chromium alloy, the raw material chemical composition mass percentage is batched and weighed, and the amount of deoxidizer C is 0.065% of the quality of the nickel-tungsten-cobalt-chromium alloy to obtain the prepared nickel-tungsten-cobalt-chromium raw material. and deoxidizer C;

[0083] S2, vacuum melting stage

[0084] The nickel-tungsten-cobalt-chromium raw material prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com