Copper foil improvement method

A technology of copper foil and template, applied in the field of copper foil improvement, can solve the problems such as the pressing quality of copper foil needs to be improved, and achieve the effects of improving the forming quality, the surface cleanliness, and the degree of lamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

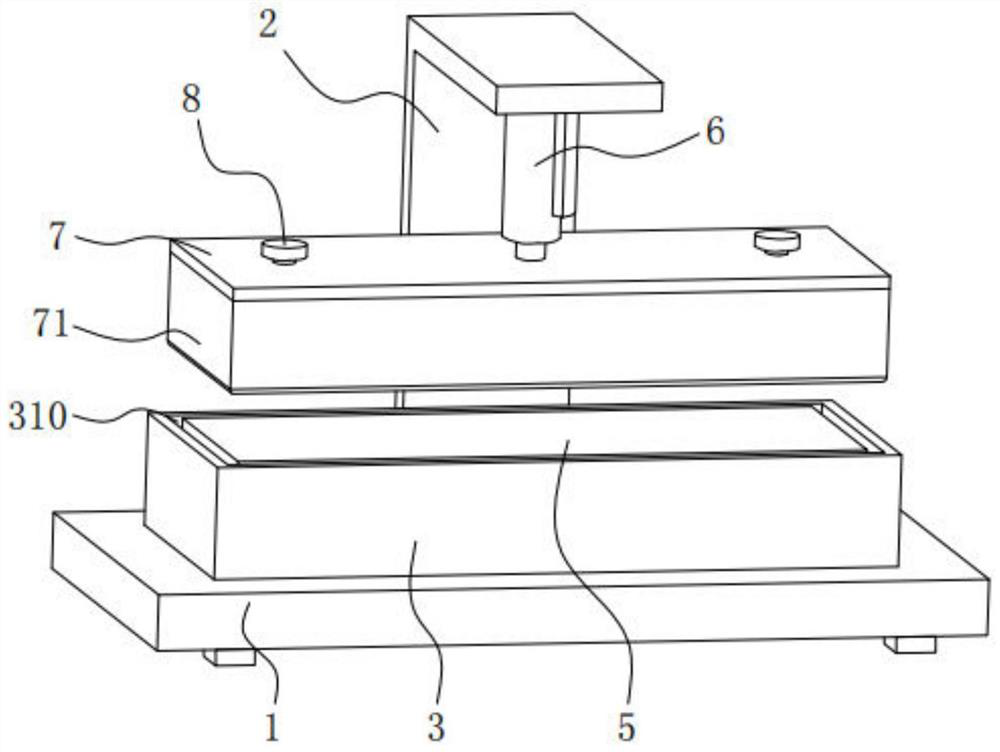

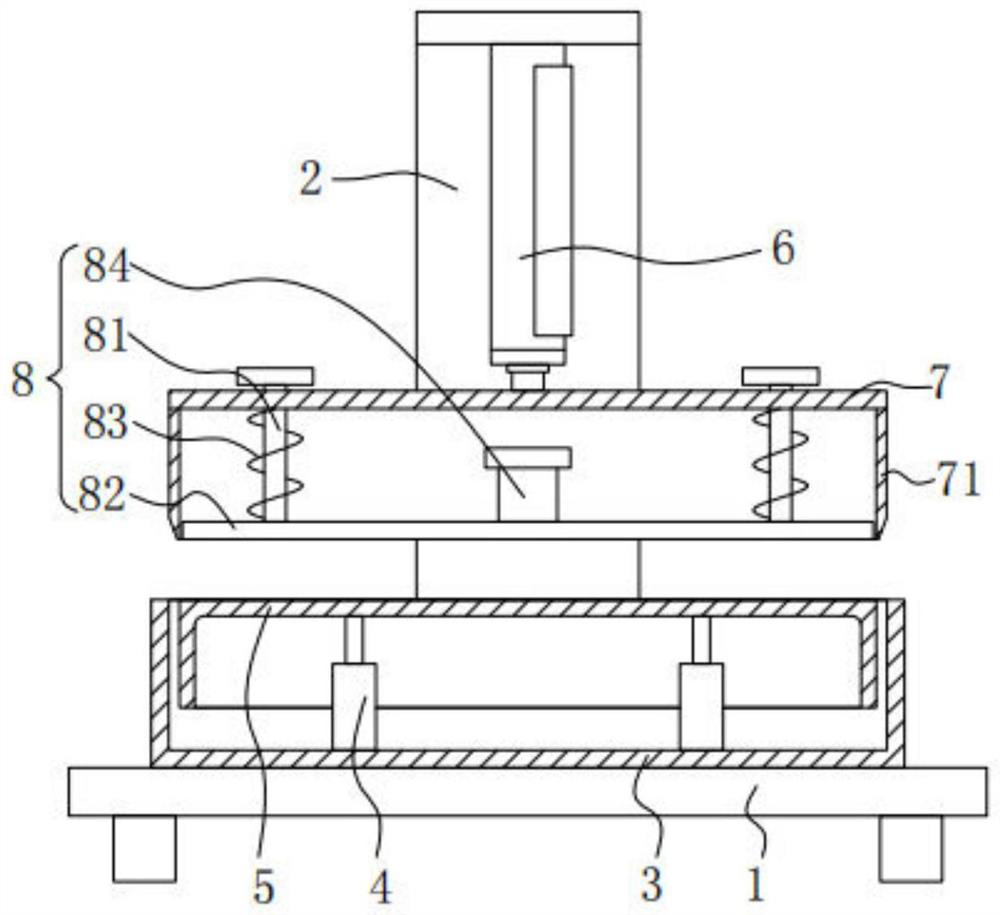

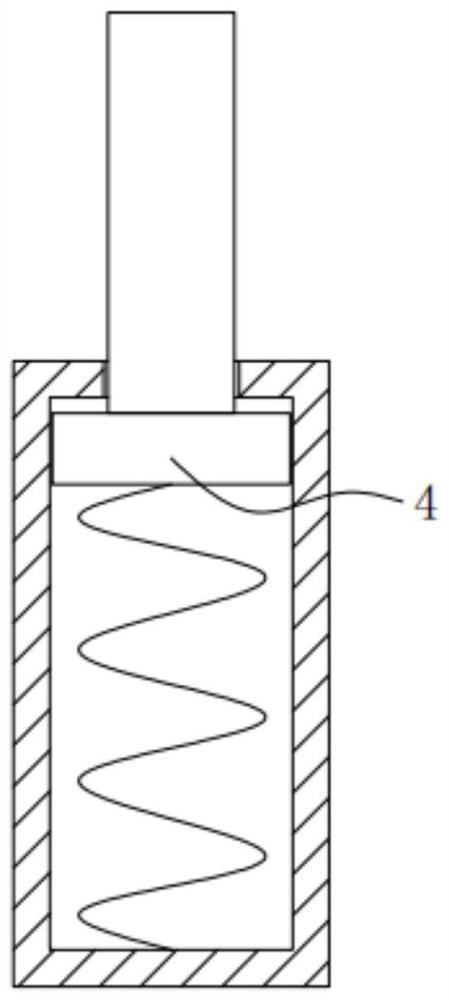

[0059] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1 It is a three-dimensional diagram of the first embodiment of the pressing device to be used in the copper foil improvement method provided by the present invention; figure 2 for figure 1 The schematic diagram of the overall structure shown; image 3 for figure 2 The schematic diagram of the structure of the spring expansion part shown; Figure 4 It is a schematic structural diagram of the pressing device that needs to be used in the copper foil improvement method provided by the present invention in a closed state; Figure 5 It is a schematic structural diagram of the pressing device to be used in the copper foil improvement method provided by the present invention in a pressing state.

[0060]A method for improving copper foil, the pressing device used in the step S3 includes: a mounting seat 1; a fixing frame 2, the fixing frame 2 is fixedly installed on the mounting sea...

Embodiment 2

[0081] see Image 6 ,Also includes:

[0082] A preheating mechanism 9, the preheating mechanism 9 includes a fan 91, a drainage pipe 92 and a heater 93, the fan 91 is fixedly installed on the pressing box 3, and a drainage is installed at the input end of the pressing box 3 Pipe 92, the input end of the drainage pipe 92 pipes through the pressing box 3 and the fixing frame 2 in turn, and the output end of the pressing box 3 is installed with a heater 93, and the heater 93 is fixedly installed in the On the press box 3.

[0083] It is convenient to preheat the lower template 5 inside the pressing box 3 through the fan 91 and the heater 93 inside the pressing box 3, so as to provide a stable constant temperature environment for the pressing environment. When the equipment is required to dissipate heat, only the When the heater 93 is turned off, the fan 91 can provide a more stable cooling air source for the lower formwork 5, and provide support for rapid cooling after the equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com