Polyester film, protective film and preparation method thereof

A technology of polyester film and protective film, which is applied in the direction of film/sheet adhesives, chemical instruments and methods, and synthetic resin layered products. problem, to achieve the effect of ensuring visibility, excellent visibility, excellent transparency and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

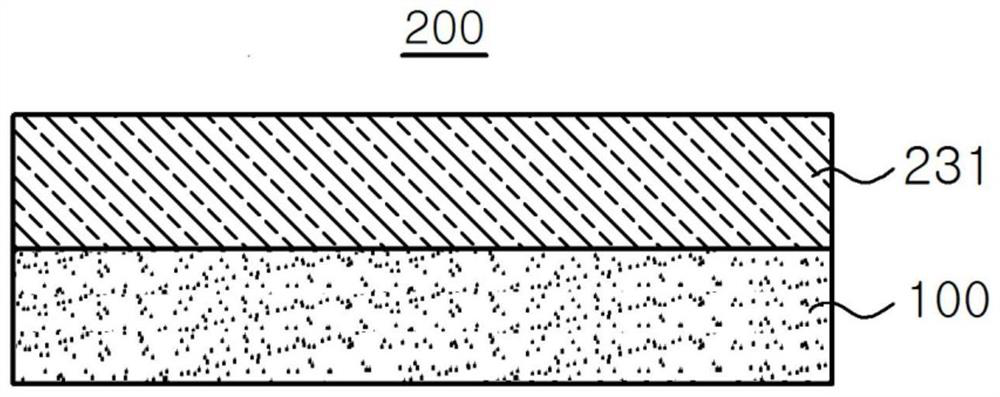

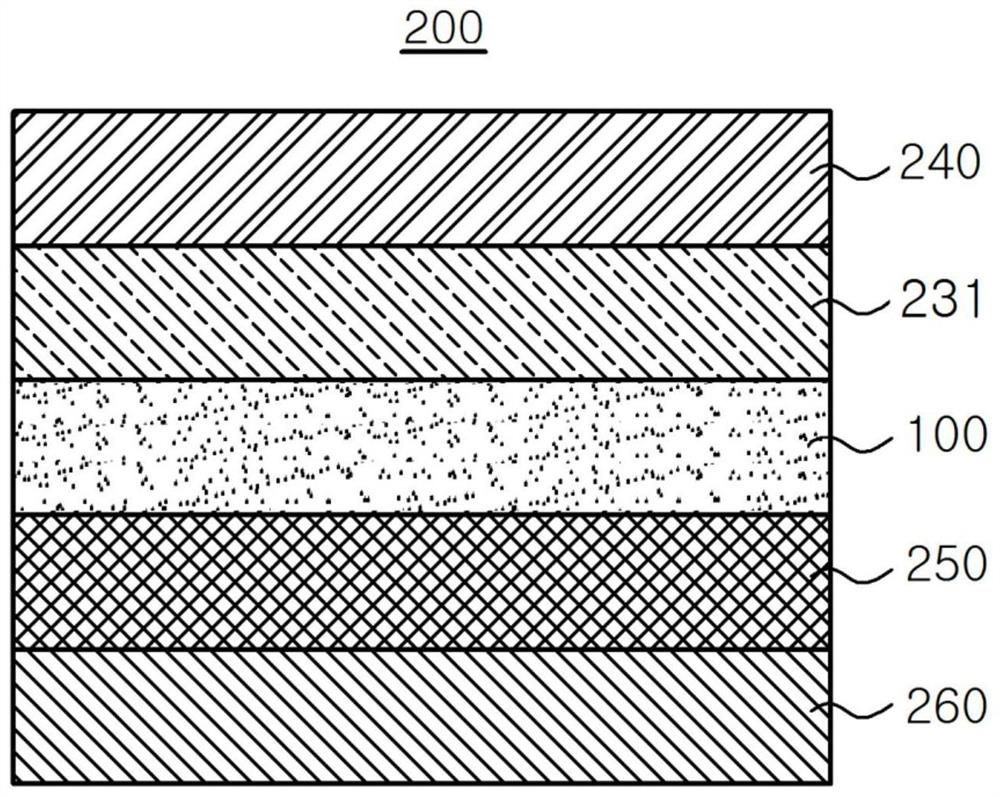

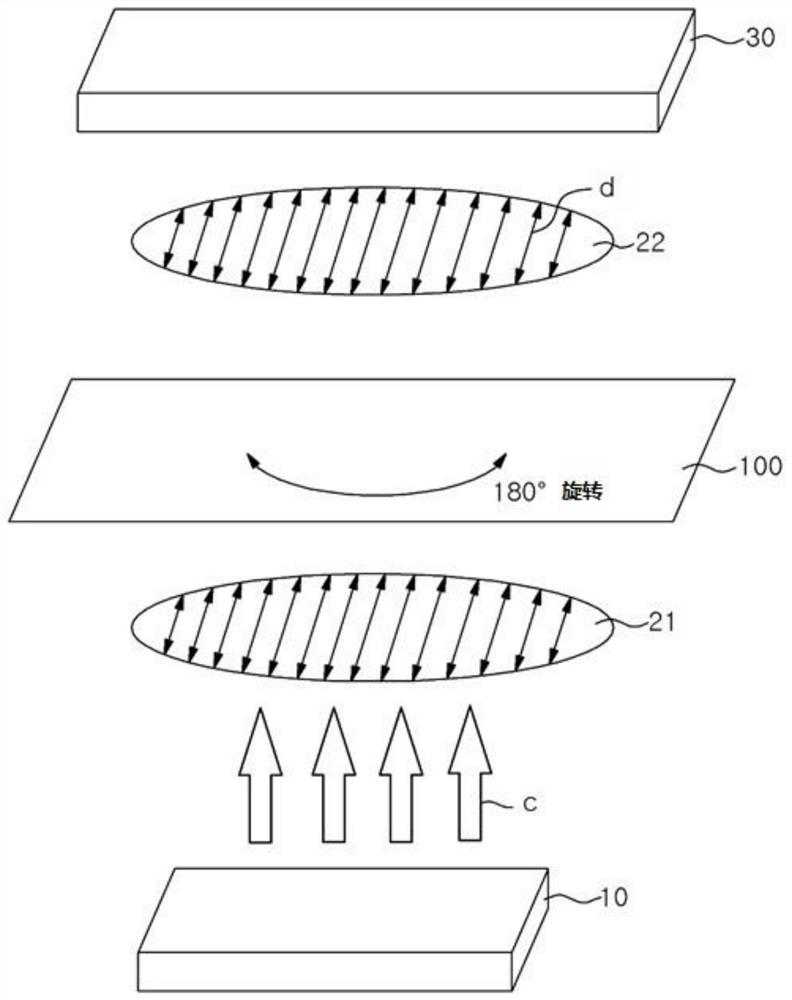

[0156] Preparation method of polyester film

[0157] A method for preparing a polyester film of another example includes: the steps of preparing a mixture of the first polyester resin and the second polyester resin; the step of melt-extruding the above mixture to prepare an unstretched sheet; at 70° C. to 125° C. The above-mentioned unstretched sheet is stretched 1 to 1.5 times along the first direction at a temperature of 100000 , and 3 to 5 times is stretched along the second direction perpendicular to the first direction to prepare a stretched film; and in The step of thermally fixing the above-mentioned stretched film at a temperature of 160° C. to 230° C. to prepare a polyester film, the above-mentioned first polyester resin contains more than 95 mole percent of terephthalic acid as a dicarboxylic acid component and terephthalic acid as a diol component. More than 95 mole percent ethylene glycol, the second polyester resin described above comprises greater than 95 mole pe...

Embodiment approach

[0308] The above is explained in more detail by way of examples. However, the following examples are only for illustrating the present invention, and the scope of the examples is not limited to the following examples.

[0309] Preparation of polyester film

Embodiment 1-1

[0311] 97 weight percent of the first polyester resin and 3 weight percent of the second polyester resin were mixed. The above-mentioned first polyester resin is a polyethylene terephthalate resin (manufacturer: SKC) which is a mixture of ethylene glycol and terephthalic acid in a molar ratio of 1:1. 77 mol% of ethylene glycol, 18 mol% of neopentyl glycol, 5 mol% of diethylene glycol as diol components and 100 mol% of terephthalic acid as dicarboxylic acid components are mixed based on the number of moles , thereby preparing the above-mentioned second polyester resin.

[0312]After the mixture of the first polyester resin and the second polyester resin was melted at a temperature of 270°C and extruded using a T-die, an unstretched sheet was prepared by cooling with a casting roll at 35°C. . The above-mentioned unstretched sheet was transferred at a speed of 16.5 m / min, preheated to 95°C, stretched 1.1 times in the MD direction at a temperature of 85°C, and stretched 4.3 time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com