Preparation method of 09MnNiD seamless steel pipe suitable for low temperature

A technology of seamless steel pipe and low temperature, which is applied in the field of seamless steel pipe manufacturing, can solve the problems of poor surface quality of steel pipe, impact energy not meeting the requirements of use, etc., and achieve the effects of short production cycle, energy saving and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

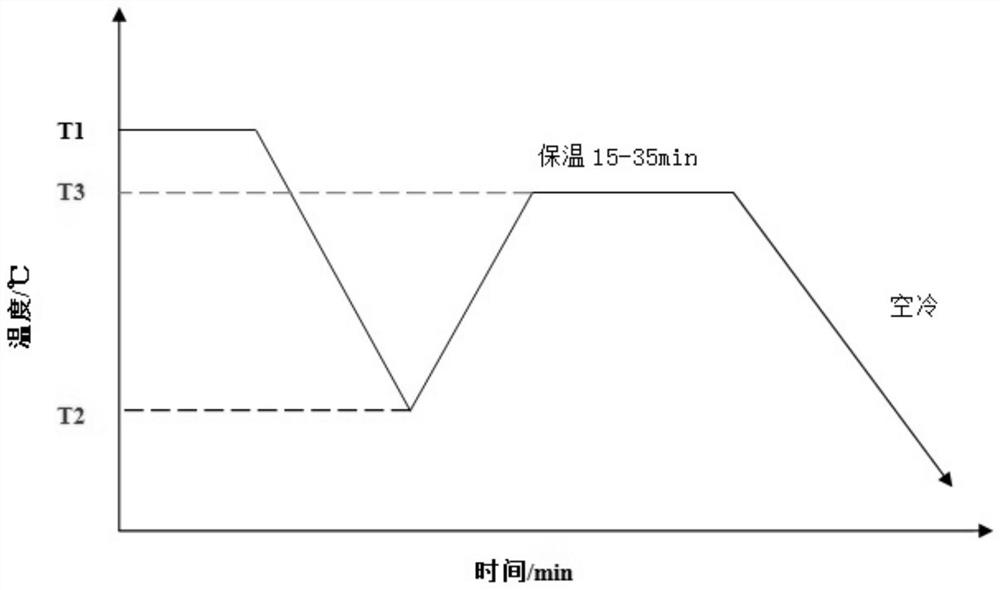

[0045] The invention provides a preparation method of a 09MnNiD seamless steel pipe suitable for low temperature, which comprises the operations of hot rolling and normalizing the pipe blank. in,

[0046] Hot rolling includes uniform heating treatment, piercing treatment, and tube rolling treatment of the tube blank;

[0047] The normalization treatment includes the steel pipe cooling treatment, reheat treatment, reduction and sizing treatment, and finishing treatment for the steel pipe after the pipe rolling treatment.

[0048]In a specific embodiment of the present invention, the tube blank is prepared by sequentially subjecting the production raw materials to smelting treatment, refining treatment, vacuum treatment, die casting treatment, ingot heating treatment, round steel rolling treatment, slow cooling treatment and finishing treatment.

[0049] The raw material for production is one or two mixtures of scrap steel and molten iron. The composition of the scrap steel sa...

Embodiment

[0082] The invention provides a preparation method of a 09MnNiD seamless steel pipe suitable for low temperature, which comprises the following steps of hot rolling and normalizing the pipe blank. in,

[0083] The tube blank is prepared by sequentially subjecting the production raw materials to smelting treatment, refining treatment, vacuum treatment, die casting treatment, ingot heating treatment, rolling round steel treatment, slow cooling treatment and finishing treatment.

[0084]The preparation process of the tube blank includes: the raw material for production is scrap steel, which is smelted in an electric furnace to obtain molten molten steel, and the ladle furnace is used to refine the molten molten steel, and the whole process is blown with Ar to stir to obtain the refined molten steel; in the process of blowing Ar, Al is added to the molten steel powder, CaSi powder diffusion deoxidation and calcium treatment; place the refined molten steel in a vacuum furnace for v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com